Environment-friendly equipment for waste gas treatment

A technology for environmental protection equipment and exhaust gas treatment, which is applied in the direction of fixed filter element filter, dispersed particle filtration, filtration and separation, etc. It can solve the problems of cumbersome disassembly of the device and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

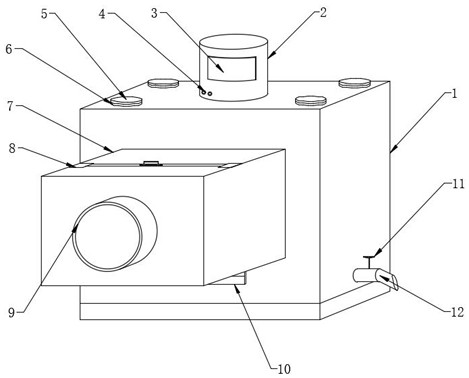

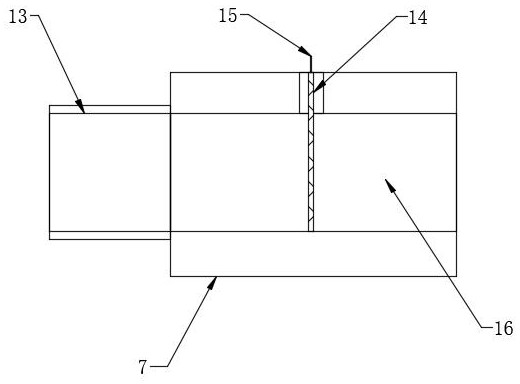

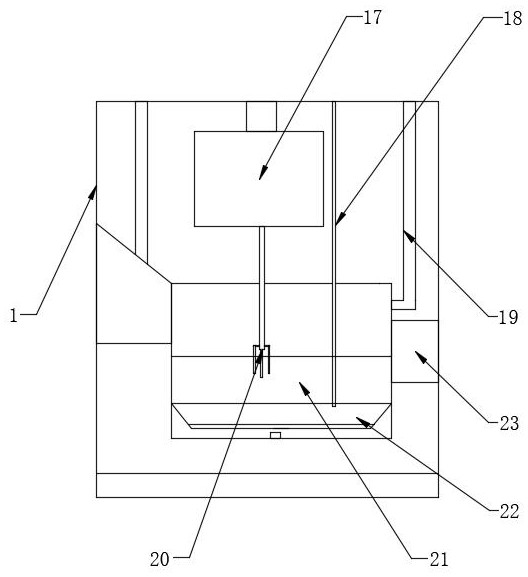

[0027] Embodiment 1: A kind of environmental protection equipment that is used for waste gas treatment, please refer to Figure 1~5 , in the present embodiment, a kind of environmental protection equipment that is used for waste gas treatment, comprises box body 1, and the front of box body 1 is equipped with filter box 7 and pull plate 10, and the front of filter box 7 is provided with connecting ferrule 9, and connecting card The inner side of the sleeve 9 is connected with an air intake channel 11, the edge of the top of the filter box 7 is fixedly connected with a block 8, the top of the box body 1 is installed with a shell 2, and the top of the box body 1 is provided with a liquid inlet hole 6 at a distance of three centimeters from the edge. , a display screen 3 and a button 4 are installed on the front of the housing 2, a drainage pipe 12 is connected to the side of the casing 1, a valve 16 is installed on the top of the drainage pipe 12, and a drive motor 17 and a disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com