A non-transmission automatic reversing structure based on machinery

A non-transmission, automatic commutation technology, applied in the field of mechanical transmission, can solve the problems of slow commutation speed and unfavorable rapid commutation, and achieve the effects of high commutation efficiency, simple adjustment and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

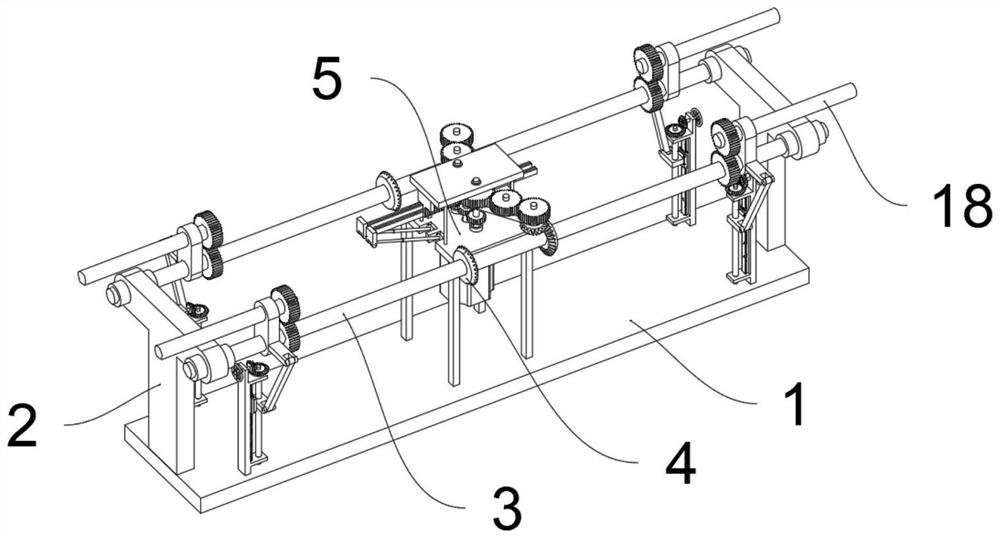

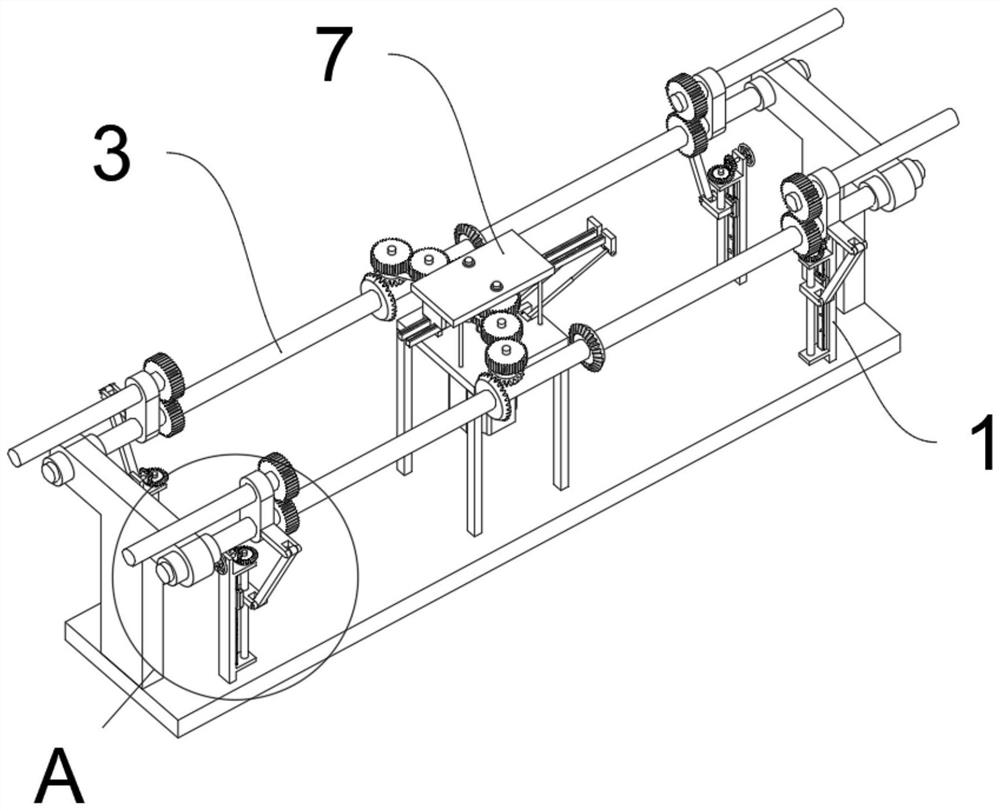

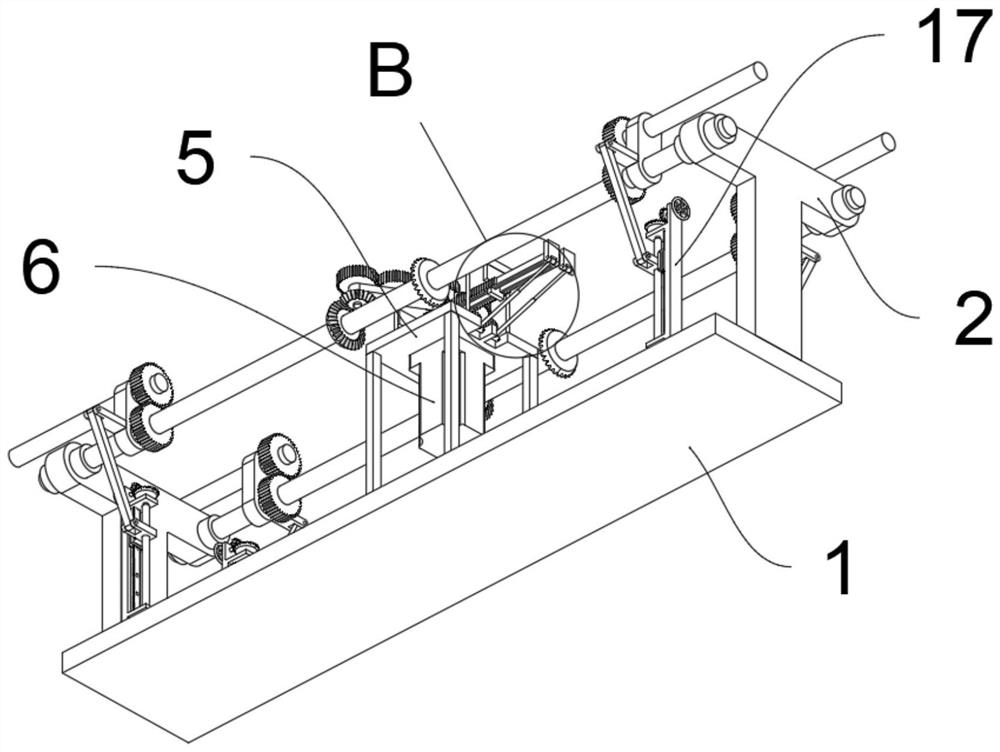

[0031] See Figure 1 to 8One embodiment of the present invention is: one is a mechanical non-conductive automatic automatic commutation structure including a base 1; two side sides of the top of the base 1 are fixedly provided with two sets of driven bobbin 2; from the moving bobbin 2 For the T-shaped structure, the two sets of two sets of driven shafts 2 are rotated between the two sets of driven shafts 3; the outer side of the driven shaft 3 is fixedly disposed with two sets of reversing gear 4, and the reversing gear 4 All are the cone gear, the same side reverse gear 4 tooth surface is opposite; the top of the base 1 is fixed to the frame 5; the intermediate bottom portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com