An insensitive warhead pressure relief structure controlled by temperature and pressure

A temperature pressure and pressure relief structure technology, applied in the direction of reducing greenhouse gases, climate sustainability, offensive equipment, etc., can solve the problems of limited strength, inability to adapt to the high penetration and overload environment of the penetration blasting warhead, and achieve good The effect of economic and social benefits

Active Publication Date: 2022-06-03

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

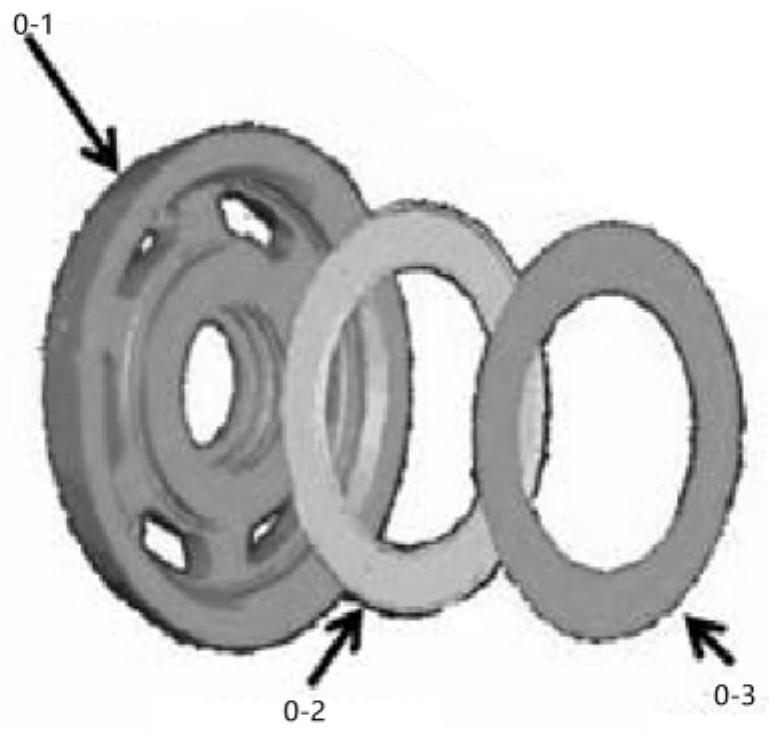

[0004] In summary, the existing airborne aerial bomb blasting warhead pressure relief structure is mainly composed of a preset destruction structure on the warhead shell or on the tail interface and a tail pressure relief structure. Specifically, the tail pressure relief structure is formed by casting Or forged ring structure 0-1, thermoplastic fusible ring 0-2, metal cover 0-3 and fixing screws, such as figure 1 As shown, the thermoplastic fusible ring 0-2 is arranged between the annular ring structure 0-1 and the metal cover 0-3, and the thermoplastic fusible ring 0-2 is fixed on the annular ring structure 0-1 through the metal cover 0-3 , its working principle is that when the pressure of the ammunition increases, the damaged structure disintegrates; when the temperature inside the ammunition rises, the thermoplastic fusible ring 0-2 melts, and the vent hole on the annular ring structure 0-1 is exposed, which plays the role of exhaust gas. , pressure relief, however, the structure itself is limited in strength and cannot adapt to the high penetration overload environment of the penetration blasting warhead, and can only be applied to ordinary blasting warheads. For example, the penetrating warhead of hard targets such as anti-reinforced concrete and ships cannot meet its use requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

[0036] The pressure relief hole is a threaded hole, and the nut cover 4-1 blocks the pressure relief hole by the thread.

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides an insensitive warhead pressure relief structure controlled by temperature and pressure, which can be applied to a high-strength and strongly restrained warhead for penetration and overload. The pressure relief structure of the present invention includes a body socket, which is connected to the tail of the warhead shell and forms an airtight integral structure with the warhead shell to ensure the integrity of the warhead structure during the penetration process; the warhead shell is provided with The pressure relief hole is provided with a charging hole on the body joint sleeve, and the pressure relief hole on the warhead shell is blocked by the pressure relief hole plugging screw composed of a nut cover with a stress groove and a fusible body in the cover, and The charging hole plugging cover with fusible core blocks the charging hole, and when the temperature and pressure reach the design value, the effective pressure relief of the high-strength and strongly restrained warhead that penetrates and overloads is realized.

Description

An insensitive warhead pressure relief structure controlled by temperature and pressure technical field The invention belongs to insensitive penetrating explosive ammunition technical field, be specifically related to a kind of insensitive temperature and pressure control Warhead pressure relief structure. Background technique [0002] During the whole life process of storage, transportation or service, ammunition will inevitably encounter falling, impact, fire or long-term violence. Exposure to unexpected thermal / mechanical stimuli such as high temperature environment will cause the explosive charge to ignite and burn until it explodes or even turns into detonation. Non-shock ignition accident reaction with catastrophic consequences. The evolution process of this non-shock ignition accident reaction is very complex, and is limited by The beam structure strength, inertial confinement ability, inherent intrinsic combustion characteristics of explosives, and crack devel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F42B12/00F42B12/04F42B12/76

CPCF42B12/00F42B12/04F42B12/76Y02E30/30

Inventor 段卓平肖川黄风雷白志玲

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com