Coal seam horizontal well hydrodynamic jet reaming coal digging and bag supporting roadway-forming pressure relief method

A hydrodynamic and horizontal wellbore technology, applied in drilling equipment and methods, drilling equipment, directional drilling, etc., can solve the problems of high risk, high difficulty and high cost, and achieve the goal of improving permeability and conductivity and improving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The above-mentioned technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some embodiments of the present invention, not all embodiments.

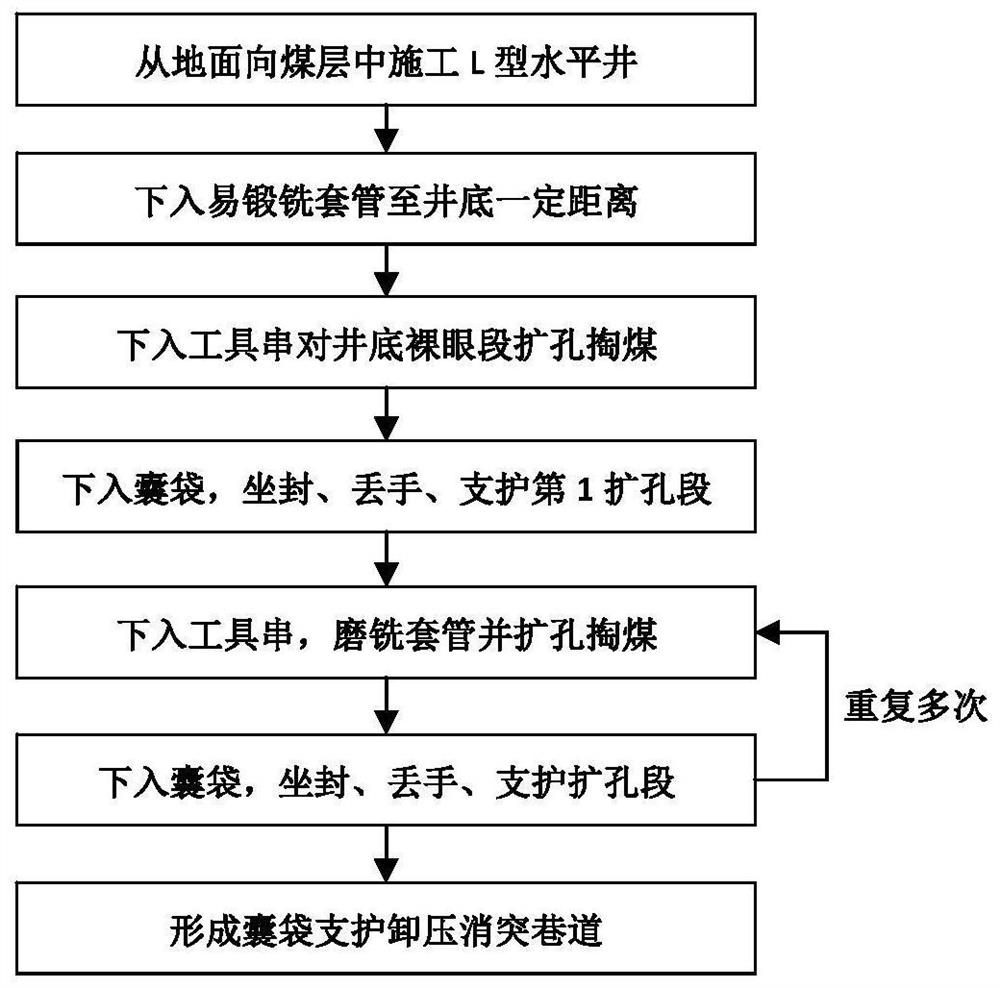

[0037] see Figure 1 to Figure 10 , shows the coal seam horizontal well hydrodynamic jet reaming coal digging and bag support forming roadway pressure relief method of the present invention.

[0038] The coal seam horizontal well hydrodynamic jet reaming hole coal removal and bag support forming roadway pressure relief method may include the following steps:

[0039] Step 1: Construct an L-shaped horizontal well in the coal seam 1, and lower the front end of the horizontal wellbore into a casing 4 made of non-metallic (such as: glass fiber reinforced plastics) for hole protection (see figure 2 ).

[0040] Preferably, the well location of the L-shaped horizontal well fully considers fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com