Precast concrete component and mounting method

A prefabricated component and concrete technology, which is applied in building construction, construction, and building materials processing, etc., can solve problems such as rising costs, and achieve the effects of improving stability, reducing production costs, and reducing adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

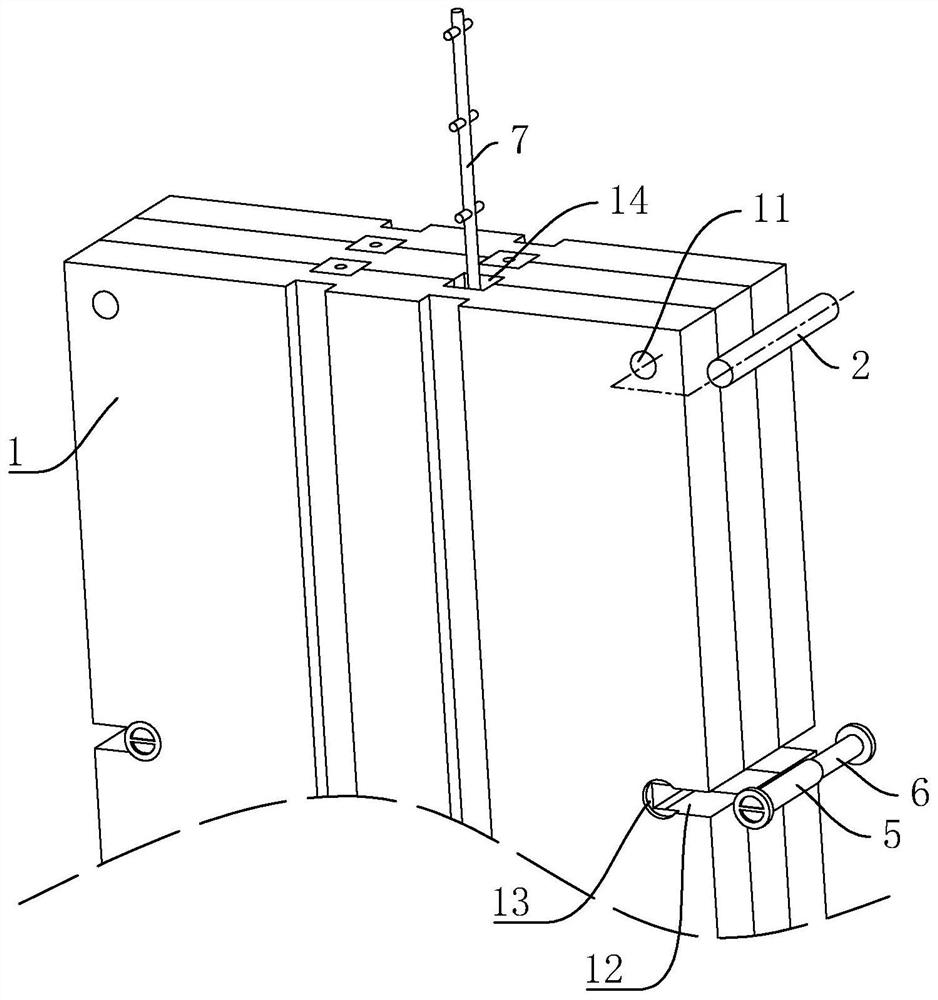

[0039] The following is attached Figure 2-4 The application is described in further detail.

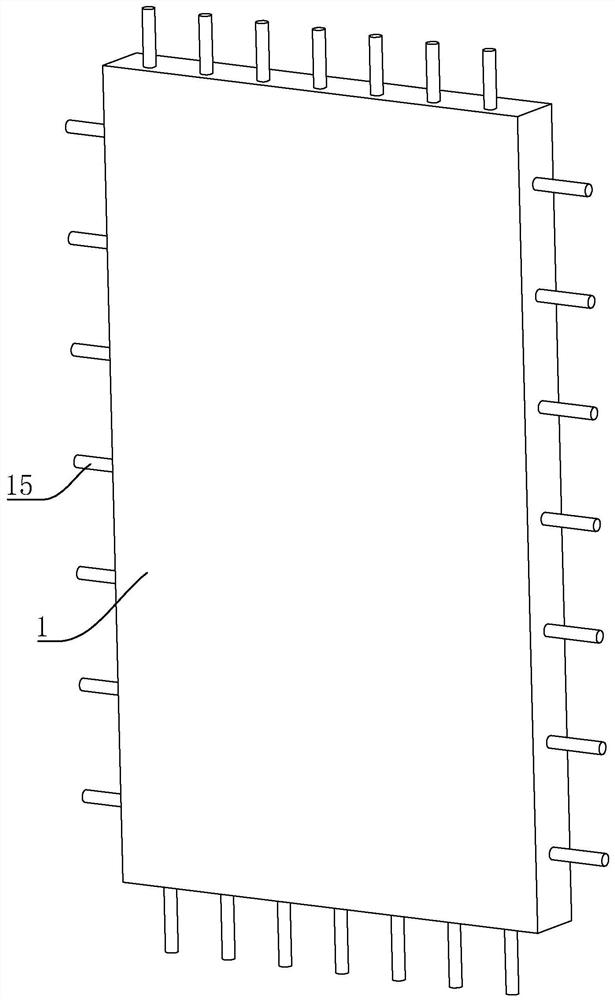

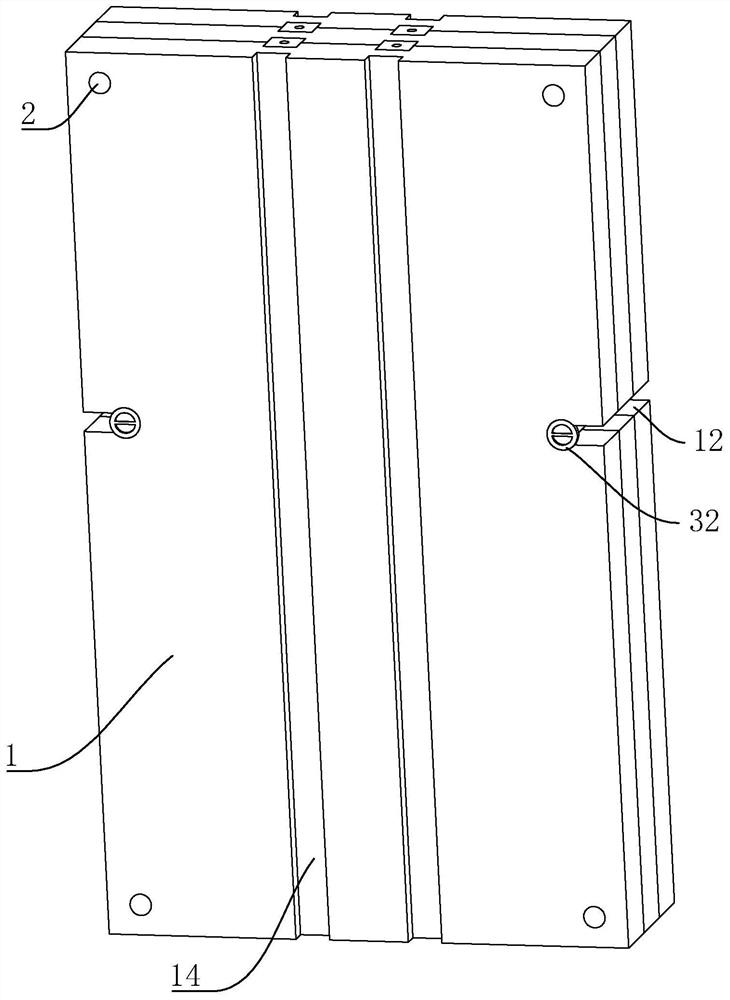

[0040] The embodiment of the present application discloses a concrete prefabricated component. refer to figure 2 , The concrete prefabricated component includes several component bodies 1 made of concrete prefabricated. Several component bodies 1 are stacked in the direction of their thickness. By selecting different numbers of component bodies 1, construction workers can realize the production of concrete prefabricated components of different thicknesses. The component bodies 1 are of conventional size, which means they can be mass-produced, thus reducing the cost of fabrication. Manpower and material costs generated by various molds.

[0041] refer to image 3 One side surface of each component body 1 is respectively provided with positioning holes 11 oppositely along its thickness direction. After adjacent component bodies 1 are laminated, the corresponding positioning holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com