Supporting leg structure of pile driver for building

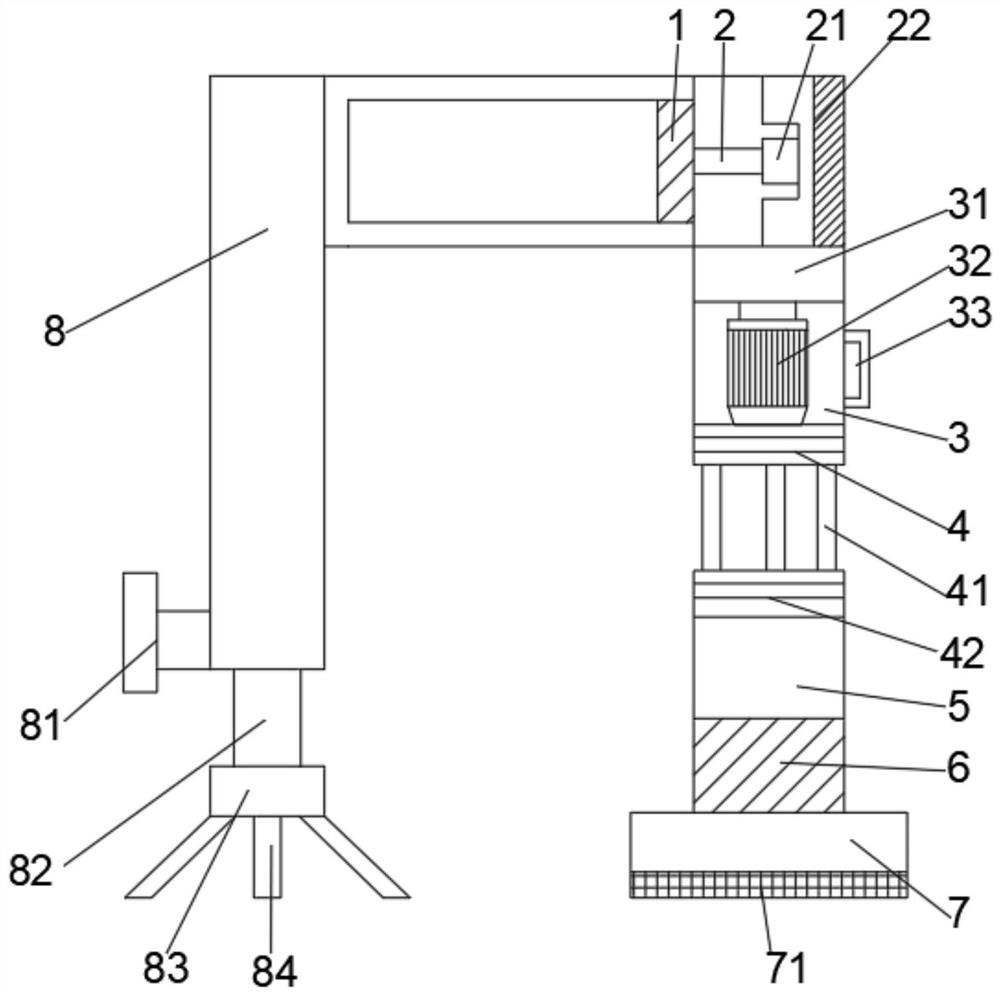

A pile driver and construction technology, applied in construction, infrastructure engineering, sheet pile walls, etc., can solve the problems of inability to achieve precise adjustment, low shock and decompression effect, and affect the piling effect, so as to improve the piling effect, Effect of reducing shaking and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

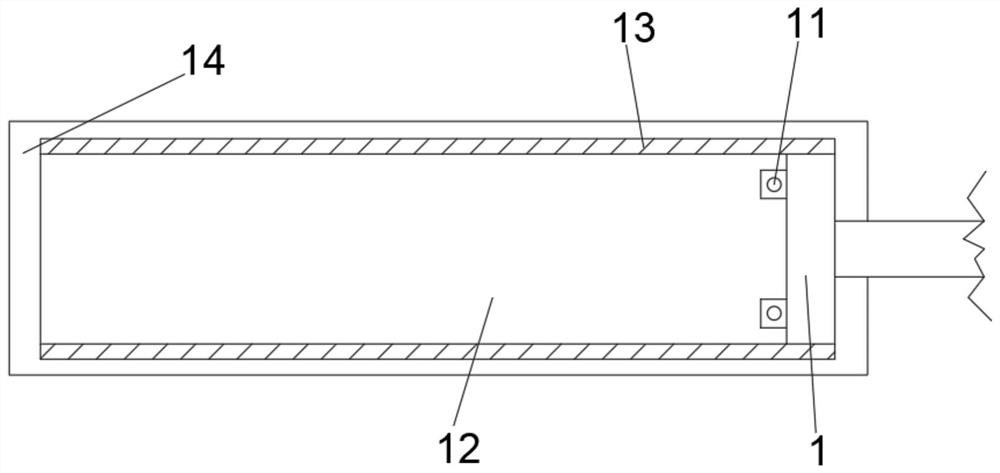

[0022] As a preferred embodiment of the present invention, two installation buttons 11 are connected to the left side of the installation plate 1, and the two installation buttons 11 are distributed symmetrically with the push rod 2 as the center. The moving cavity 12 is provided with sliding grooves 13 on the upper and lower sides of the moving cavity 12, and the upper side of the sliding groove 13 is provided with a mounting frame 14, which facilitates movement and speeds up work efficiency.

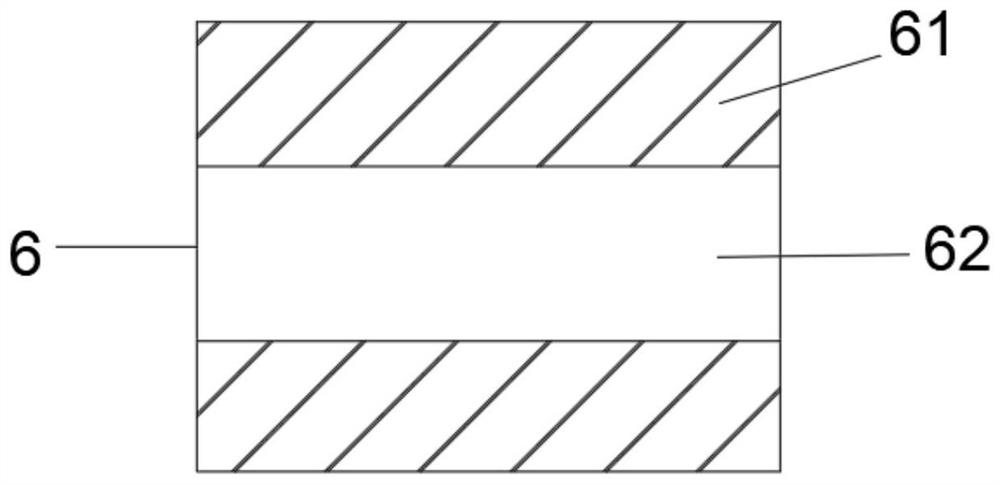

[0023] As a preferred embodiment of the present invention, a connecting plate 62 is arranged in the middle of the decompression pad 6, and cushioning pads 61 are installed on the upper and lower sides of the connecting plate 62 to avoid deformation and movement caused by excessive pressure. , to improve security.

[0024] As a preferred embodiment of the present invention, a rotary switch 81 is provided on the left side of the auxiliary bracket 8, a support rod 82 is connected to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com