A treatment method for efficient and stable treatment of municipal sludge

A technology for stabilization treatment and municipal sludge, applied in pyrolysis treatment of sludge, fertilizer treatment control, chemical instruments and methods, etc., can solve the loss of easily degradable organic matter, it is difficult to support subsequent heap heating and continuous high temperature, and it is not considered. Excessive temperature, inactivation of functional flora, unfavorable organic matter resources, etc., achieves the effect of reducing heat loss, long duration of high temperature, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

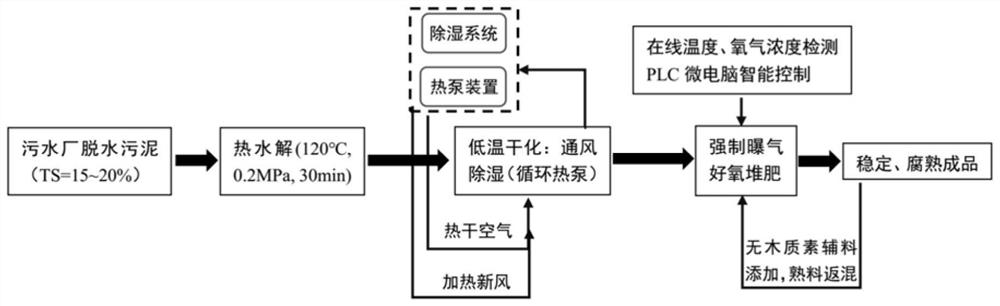

Method used

Image

Examples

Embodiment 1

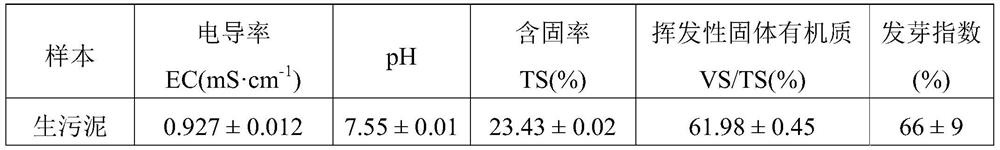

[0039] The results show that the experimental group 1# has a better stabilization effect. After the experimental group 1# entered the compost, it quickly heated up to above 55 ℃ within 24 hours, and the highest temperature was 65.5 ℃. Compared with the control group, the compost body maintained above 55 ℃ for 1.5 times longer to 5.5 days; the experimental group 1# eventually volatilized The degradation rate of perishable solid organic matter reached 48.75% and the control group 1# was 38.21%; the conductivity of the experimental group changed more drastically and the final conductivity was lower, that is, by reflecting the change of salt content, it indicated that the decomposition of perishable organic matter was more thorough and the final free content The salt content was controlled, and the more significant pH rise of the experimental group further indicated that the conversion of nitrogenous substances was more efficient; the germination index of control group 1# was 53% a...

Embodiment 2

[0041] The results showed that, compared with the control group, the temperature of the 2# pile in the experimental group was more rapid, the time of maintaining above 55 °C was extended by 2 times to 8 days, the highest temperature was 64.6 °C, the degradation rate of volatile organic matter solids increased by 13.6%, and the germination index of the final product was increased. It nearly doubled to 157%, indicating that the phytotoxicity of the finished sludge product was removed and had a certain fertilizer effect.

[0042] Further, compared with the experimental group 1#, the degradation rate of volatile solid organic matter in the experimental group 2# was increased by 10.05%, but the ammonia nitrogen release and biodegradation in the experimental group 2# was still relatively active in the later stage of composting, so the salt content of the final product was Compared with the experimental group 1#, the germination index was lower.

Embodiment 3

[0044] The results showed that the temperature of the experimental group 3# increased rapidly to above 55 °C within 48 hours after entering the compost, and the highest temperature was 62.3 °C. The final volatile solid organic matter degradation rate of 3# was 56.47% and that of control group 1# was 49.01%; the final germination index of control group 3# was 83%, while the germination index of experimental group 3# increased to 123% at the end, and it has an excellent garden. Characteristics of nutrient soils.

[0045] Further, compared with the experimental group 1#, the degradation rate of volatile solid organic matter in the experimental group 3# was increased by 7.72%, and the germination index was increased by 30%; and compared with the experimental group 2#, the final volatile organic matter degradation rate in the experimental group 3# was increased by 7.72%. There is no increase but a decrease of 2.33%, and the germination index decreases by 34%, indicating that the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com