Support bonding equipment and bonding method

A bonding method and bonding technology, applied in mechanical equipment, lighting and heating equipment, connecting components, etc., can solve the problems of low production efficiency, inability to bond different types of brackets, high cost, etc., and achieve high production efficiency and improve Bonding accuracy and work efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

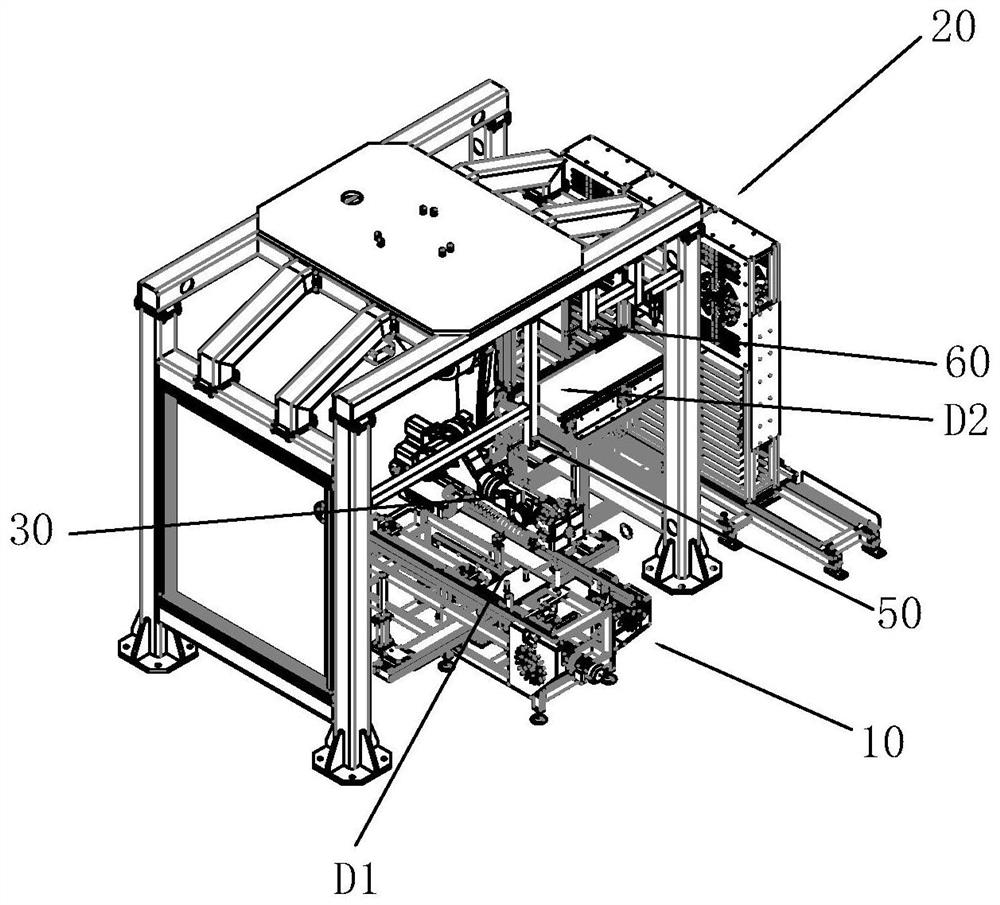

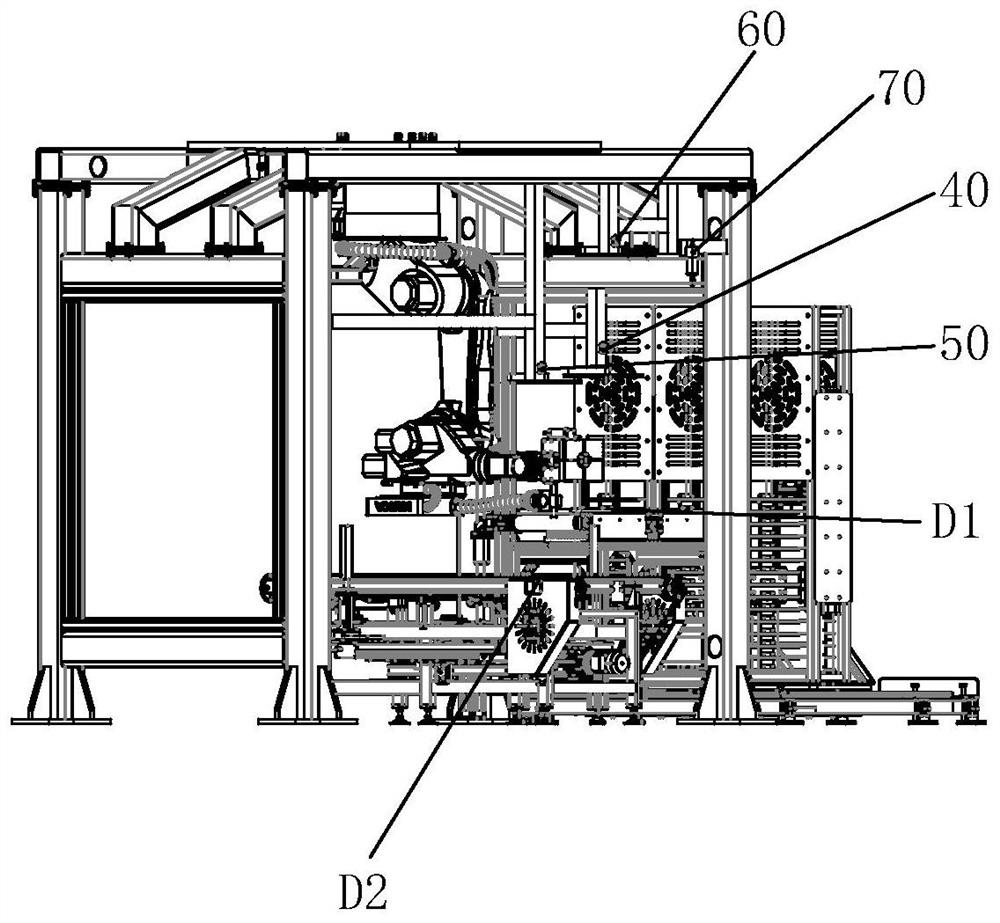

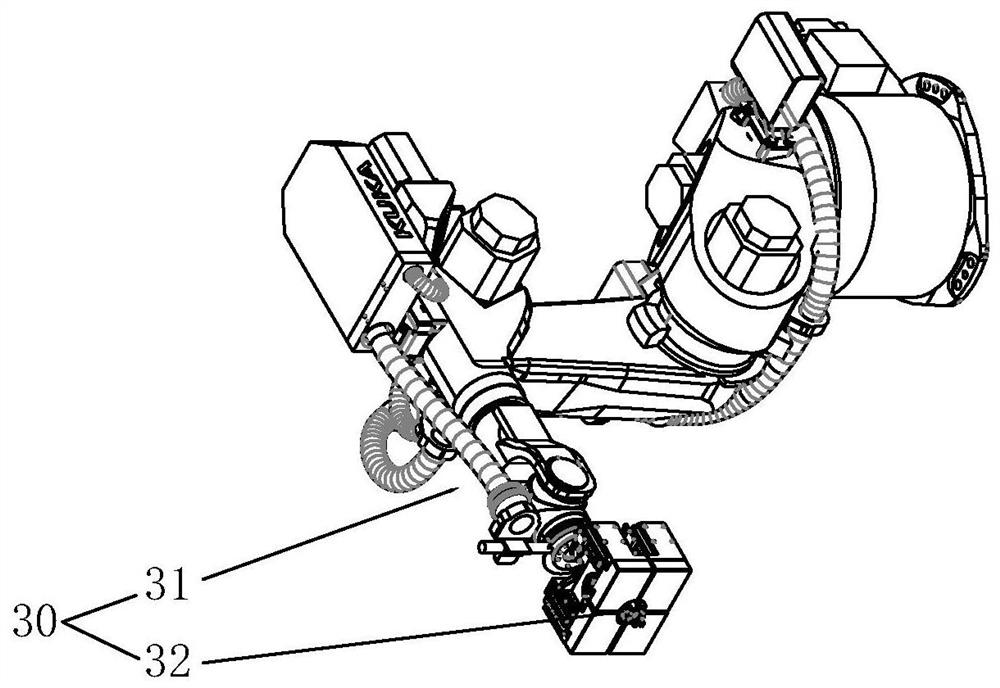

[0034] Please refer to figure 1 , figure 2 , Figure 4 as well as Figure 6, the present embodiment provides a bracket bonding equipment, which is characterized in that it includes: a glass plate conveying device 10, a support 100 conveying device 20, a clamping device 30, and a control device; the glass plate conveying device 10 is used to transport the glass plate to the first position D1; the stent 100 delivery device 20 is used to transport the stent 100 to the second position D2; the clamping device 30 can move to the second position D2 to clamp the stent 100, and stick the stent 100 to the A preset area on the surface of the glass plate at the first position D1; a twistable post 101 is arranged on the side opposite to the bonding surface of the support 100, and the clamping device 30 includes: a manipulator 31. Clamping mechanism 32 and clamping mouth; Clamping mechanism 32 is connected to the working end of described manipulator 31, and has at least one pair of mout...

Embodiment 2

[0054] Please refer to Figures 1 to 6, this embodiment provides a bracket bonding method applied to the above-mentioned bracket bonding equipment. For the structure of the bracket bonding equipment, refer to the content of the embodiment. The bracket bonding method includes the following steps:

[0055] S10. The glass conveying device conveys the glass plate to the first position D1;

[0056] S20. The stent 100 transport device 20 transports the stent 100 to the second position D2;

[0057] S30. The adjustment mechanism 13 lifts up the glass plate located in the first position D1, and adjusts the angle of the preset area on the glass plate relative to the horizontal plane;

[0058] S40. The centering mechanism 12 centers the glass plate lifted by the adjustment mechanism 13;

[0059] S50. The first visual device 40 obtains the first information including the type information of the support 100 and the position information of the column 101 of the support 100, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com