Aluminum extrusion profile bracket structure

A bracket structure and aluminum extrusion technology, applied in the field of auto parts, can solve the problems of increasing the development cost of the body, unfavorable weight reduction of the body, and increasing the number of parts, and achieve the effects of novel structure, low cost, and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

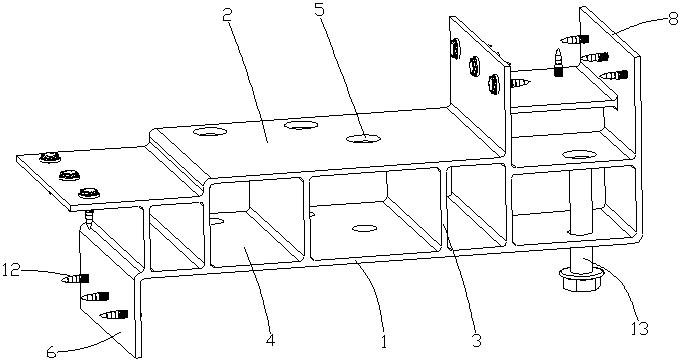

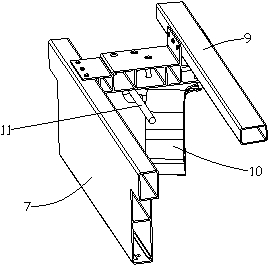

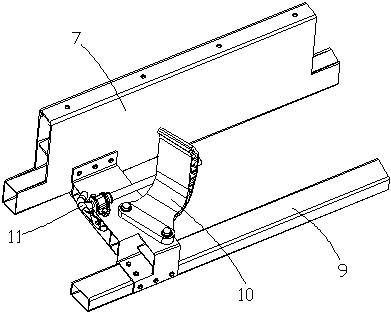

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment: According to Figure 1 to Figure 3 The shown aluminum extruded profile bracket structure includes a support base plate 1 and a support upper plate 2 parallel to each other, and a plurality of intermediate support reinforcement plates 3 are arranged between the support base plate 1 and the support upper plate 2, and the middle A plurality of lightening holes 4 are formed between the support reinforcement plates 3, and the support base plate 1 and the support upper plate 2 are provided with a plurality of bolt connection holes 5, and the left side of the support base plate 1 is provided with a left connection plate 6, so The left connecting plate 6 is perpendicular to the supporting base plate 1, the left connecting plate 6 is provided with a front connecting beam 7, and the right side of the supporting upper plate 2 is provided with a U-shaped connecting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com