Knee joint driven by flexible driver

A flexible driver and knee joint technology, applied in the field of bionic robots, can solve problems such as difficult control, large hysteresis, and low driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described below with reference to the accompanying drawings.

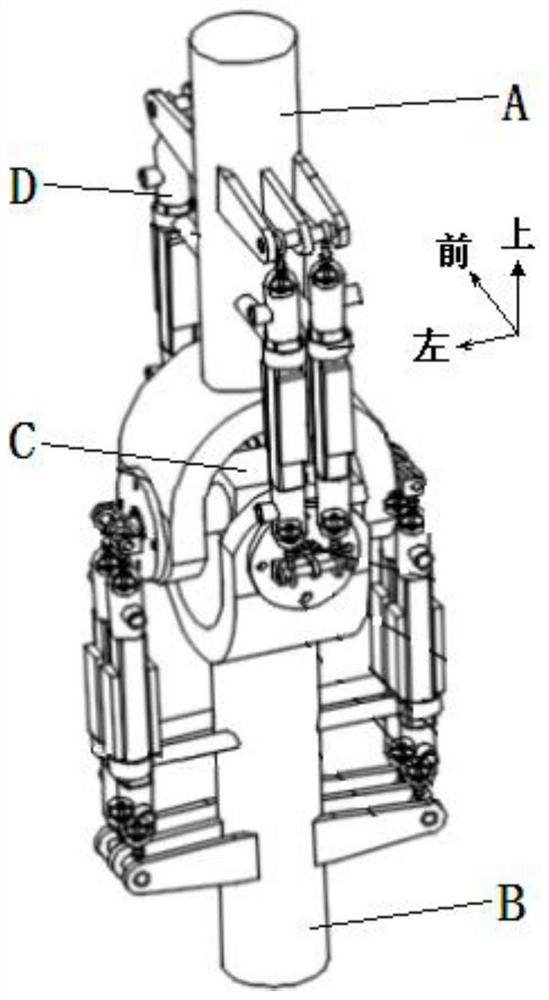

[0054] like figure 1 , Figure 18 and Figure 19 As shown, the present invention consists of a bionic femur A, a bionic tibia B, a bionic cruciate ligament C, and a flexible actuator D, wherein the bionic femur A and the bionic tibia B are arranged up and down, and the bionic cruciate ligament C is located at the bionic femoral condyle 29 and the bionic femur A of the bionic femur A. Between the bionic tibial condyles 38 of the tibia B.

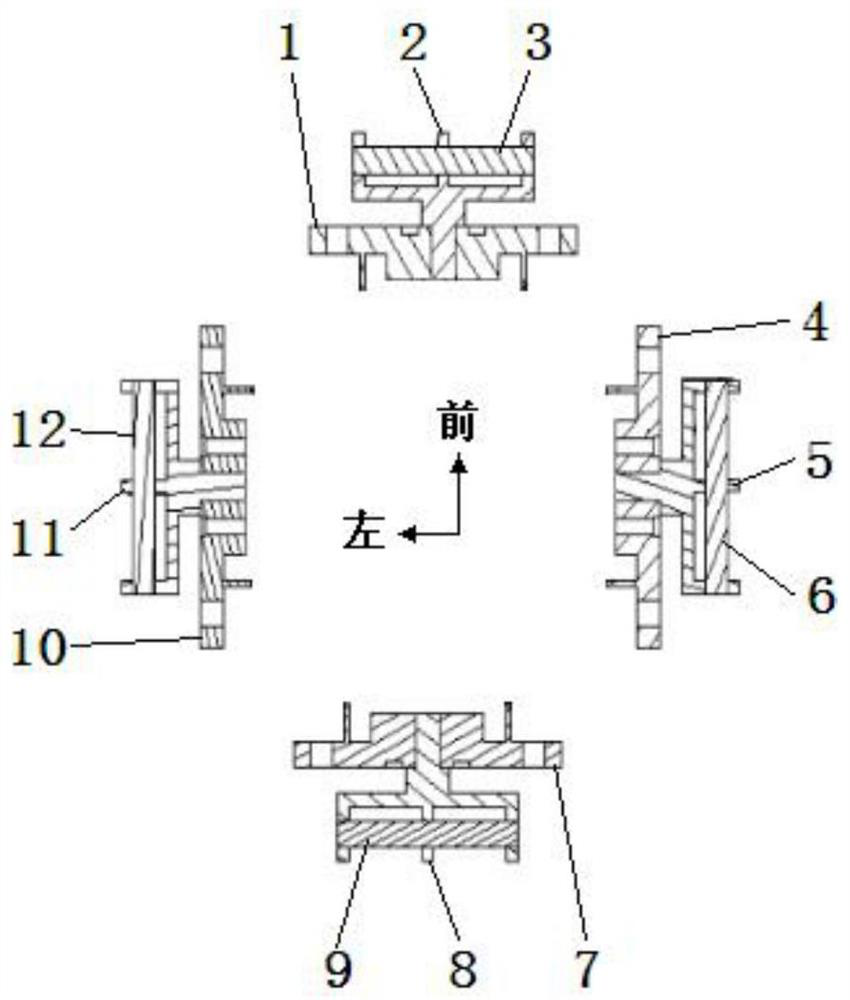

[0055] The outer ring of the anterior bearing 14 in the artificial cruciate ligament C is connected with the anterior hole 52 of the bionic tibia B; the outer ring of the middle and posterior bearing 16 of the artificial cruciate ligament C is connected with the middle and posterior hole 37 of the bionic tibia B by interference; the middle left of the artificial cruciate ligament C The outer ring of the bearing 15 is connected with the left h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com