Processing method of flower-fragrance mellow-taste dark tea

A technology with a mellow flavor and a processing method, applied in the direction of tea treatment before extraction, can solve the problems of backward processing technology, sour mold, turbid soup, etc., and achieve the effect of increasing the frequency of exercise and increasing the concentration of tea soup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

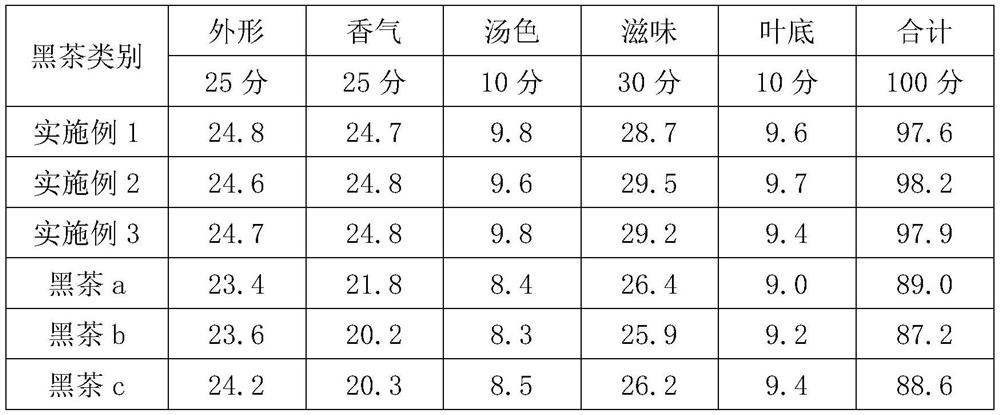

Examples

Embodiment 1

[0030] Drying, fresh leaves are quickly cooled after picking, spread in the sun for 12-15 minutes, temperature 28-35°C, leaf thickness 3.5-4cm, stir twice during the drying process; fresh leaves after drying Move it indoors, let it stand for 6 hours, and turn it by hand every 2 hours. After spreading, the fresh leaves will wither and the water content will be 68%-70%.

[0031] To do greening, the fresh leaves after sun-drying are combined with cold wind withering and greening, and greening is done during the cold wind withering process, and greening is done every 35 minutes.

[0032] Shake green, after the fresh leaves wither, carry out 3 shake green, each shake green interval 35 minutes.

[0033] Spread out, and spread out for 100 minutes after the fresh leaves are shaken green.

[0034] For greening, use a bottle-type frying machine to kill the fresh leaves treated by the fragrance process at 220°C for 4 minutes.

[0035] Knead, knead for 30 minutes immediately after the f...

Embodiment 2

[0041] Drying, fresh leaves are quickly cooled after picking, spread in the sun for 12-15 minutes, temperature 28-35°C, leaf thickness 3.5-4cm, stir twice during the drying process; fresh leaves after drying Move it indoors, let it stand for 6 hours, and turn it by hand every 2 hours. After spreading, the fresh leaves will wither and the water content will be 68%-70%.

[0042] To do greening, the fresh leaves after sun-drying are combined with cold wind withering and greening, and greening is done during the cold wind withering process, and greening is done every 35 minutes.

[0043] Shake green, after the fresh leaves wither, shake green 3 times, each shake green interval 40 minutes.

[0044] Spread, shake the fresh leaves and spread for 110 minutes.

[0045] For greening, use a bottle-type frying machine to kill the fresh leaves treated by the fragrance process at 220°C for 4 minutes.

[0046]Knead, knead for 30 minutes immediately after the fresh leaves are finished, duri...

Embodiment 3

[0052] Drying, fresh leaves are quickly cooled after picking, spread in the sun for 12-15 minutes, temperature 28-35°C, leaf thickness 3.5-4cm, stir twice during the drying process; fresh leaves after drying Move it indoors, let it stand for 6 hours, and turn it by hand every 2 hours. After spreading, the fresh leaves will wither and the water content will be 68%-70%.

[0053] To do greening, the fresh leaves after sun-drying are combined with cold wind withering and greening, and greening is done during the cold wind withering process, and greening is done every 35 minutes.

[0054] Shake green, after the fresh leaves wither, shake green 3 times, each shake green interval 45 minutes.

[0055] Spread, shake the fresh leaves and spread for 120 minutes.

[0056] For greening, use a bottle-type frying machine to kill the fresh leaves treated by the fragrance process at 220°C for 4 minutes.

[0057] Knead, knead for 35 minutes immediately after the fresh leaves are finished, dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com