Preparation method of LED epitaxial wafer distributed Bragg reflector

A technology of LED epitaxial wafers and Bragg reflectors, which is applied in sputtering coating, ion implantation coating, coating, etc., can solve the problem of poor bonding between the first DBR layer and LED epitaxial wafers, and uneven refractive index of the first DBR layer. Meet the requirements and other issues, to achieve the effect of stable refractive index, not easy to fall off, strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

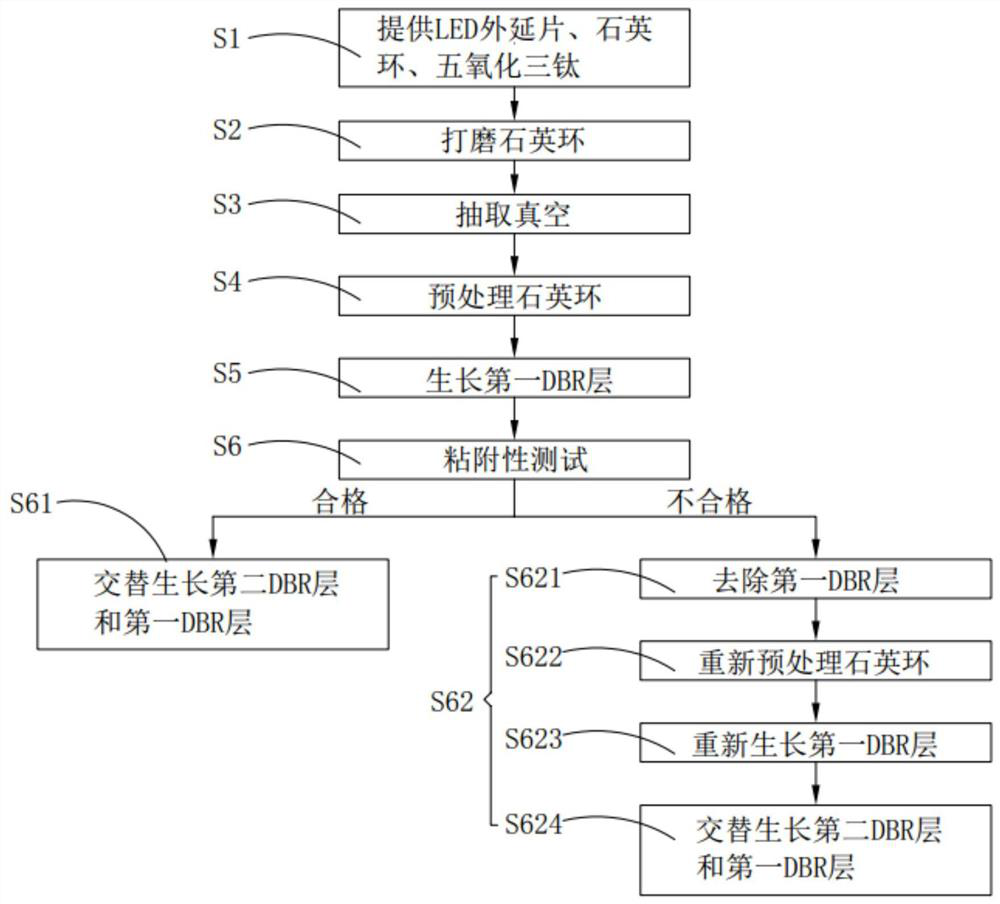

[0029] One embodiment of the present invention provides a method for preparing a distributed Bragg reflector of an LED epitaxial wafer, by which a distributed Bragg reflector having a first DBR layer and a second DBR layer is formed on the back of the LED epitaxial wafer structure. In the present invention, the number of the first DBR layer and the number of the second DBR layer are at least one, and the number of the two is the same.

[0030] The methods include:

[0031] Rotate the quartz around its central axis by a first angle in a first direction, so that the electron beam sweeps the fan-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com