Environment-friendly seabed reef cleaning construction process

A construction technology and environment-friendly technology, which is applied in the field of marine dredging engineering, can solve the problems of low work efficiency of the hammer impact rock drilling method, achieve the effect of reducing construction cost, reducing impact and improving construction efficiency

Active Publication Date: 2020-11-06

HOHAI UNIV

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Purpose of the invention: In view of the safety and environmental threat problems existing in the current underwater blasting reef clearing method and the low work efficiency of the hammer impact rock drilling method, the present invention provides an environmentally friendly seabed that is safe and environmentally friendly and can effectively improve construction efficiency. Reef Clearing Construction Technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

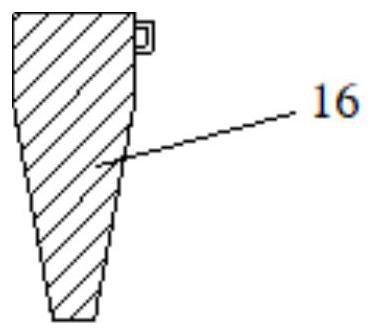

[0059] During the construction of an immersed tube tunnel across the river, there are a large amount of slightly weathered granite within the design elevation range of the foundation trench of the immersed tube tunnel, and its saturated uniaxial compressive strength is between 90 and 150 MPa. Therefore, rock drilling technology is used to perform dynamic crushing on hard reefs.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Login to View More

Abstract

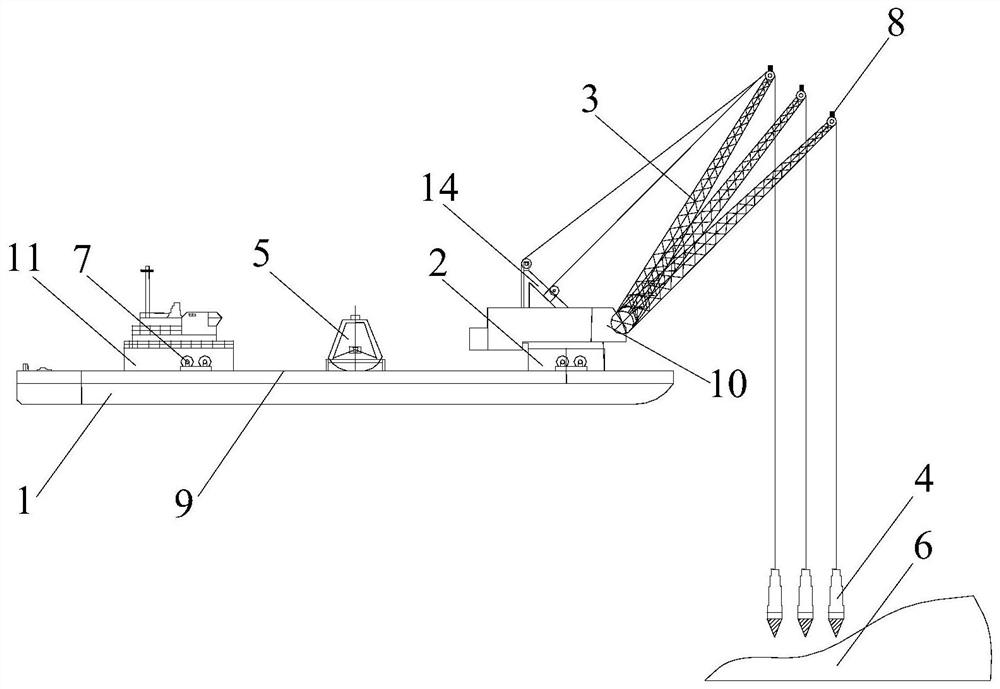

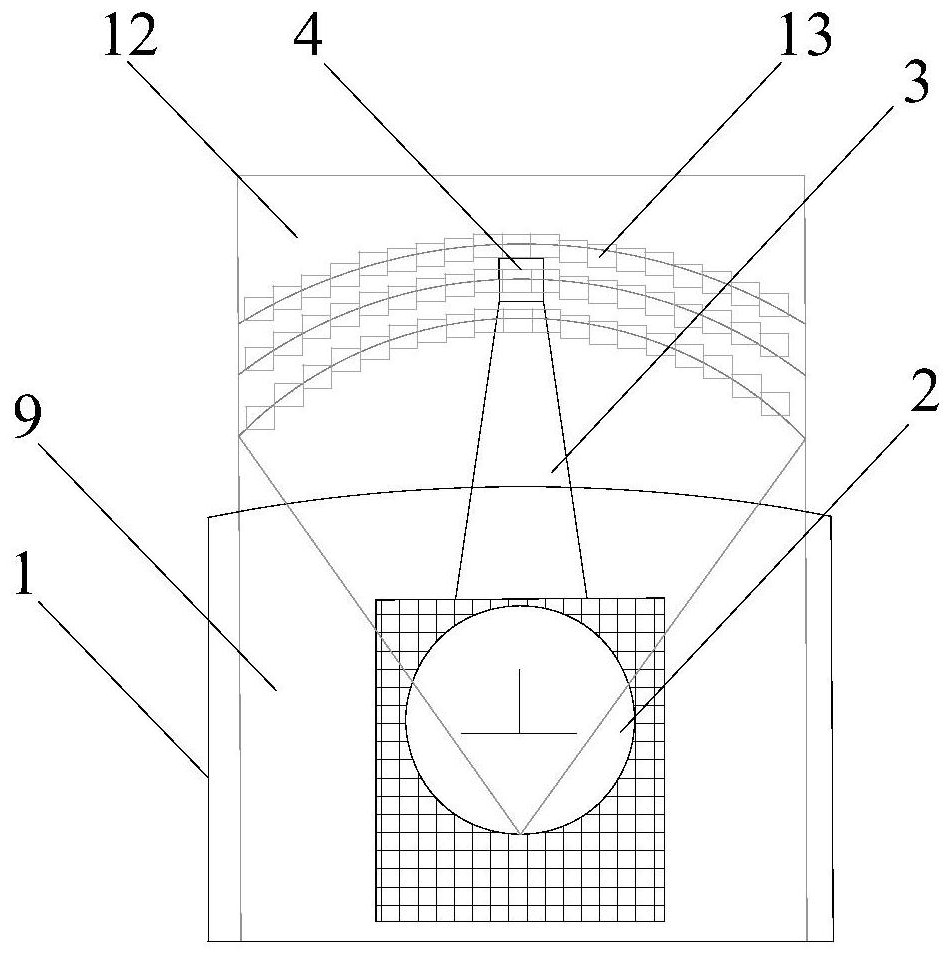

The invention discloses an environment-friendly seabed reef cleaning construction process. The environment-friendly seabed reef cleaning construction process comprises the following steps that an offshore rock drilling platform is driven to a position above a to-be-cleaned reef and then is fixed and located; an industrial test of the crushing effect on a typical area is carried out; according to the test result, rock drilling construction parameter sensitivity analysis is carried out, regression analysis is carried out on the rock drilling effect evaluation index, and rock drilling construction parameters of a reef clearing area are calculated; a three-dimensional geomorphologic map of the reef clearing area is established; rock drilling points are arranged, rock drilling and crushing areconducted at all the rock drilling points through rock drilling rods, and crushed reefs are cleaned through a grab bucket; and the offshore rock drilling platform is driven out of the reef clearing area, the three-dimensional geomorphologic map of the reef clearing area is re-established and analyzed, and construction is stopped until reef clearing is conducted to the designed elevations of all the areas. By means of the construction process, excavation of a seabed foundation trench can be accurately and efficiently achieved, construction errors are effectively reduced, the repeated construction operation condition caused by under-excavation and over-excavation is avoided, the construction efficiency is greatly improved, and the construction cost is reduced.

Description

technical field [0001] The invention relates to a seabed reef cleaning process, in particular to an environment-friendly seabed reef cleaning construction process, which belongs to the technical field of marine dredging engineering. Background technique [0002] In the process of waterway regulation or subsea tunnel foundation trench excavation, in order to meet the needs of shipping water depth and engineering construction, it is necessary to remove the subsea reefs. At present, the most commonly used method is underwater blasting to clear reefs, which is not applicable in areas with strict environmental requirements, such as areas with dangerous goods in the surrounding area or marine ecological protection areas. [0003] Using underwater blasting to clear reefs will not only generate huge blasting vibrations, but also generate water shock waves and swell waves, which pose a greater safety threat to construction workers, construction ships and passing ships. Therefore, du...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02B3/02E02F5/30E02F5/28

CPCE02B3/026E02F5/30E02F5/28

Inventor 王环玲屈晓刘士奇马行生

Owner HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com