Ionic liquid and application thereof in sulfur dioxide absorption

A technology of ionic liquid and sulfur dioxide, which is applied in separation methods, gas treatment, organic chemistry, etc., can solve problems such as insufficient capture capacity, impact on industrial applications, poor cycle performance, etc., and achieve high SO2 absorption, low toxicity, and volatile Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 61.08g of ethanolamine and 61g of water into the flask, take 83.06g of phthalic acid in the constant pressure dropping funnel according to the molar ratio of ethanolamine and phthalic acid of 2:1, slowly titrate at room temperature, and then heat up to 80°C to react after the titration End after 3h. The ionic liquid solution prepared by the reaction is light yellow liquid with good fluidity.

[0026] Mix and dilute the above-mentioned ionic liquid aqueous solution and water at a volume of 1:1, take 5ml of the diluted ionic liquid solution as an absorption liquid and put it in a reaction bottle, adjust the gas flow rate to 50ml / min, and dissolve the SO 2 The gas was connected to the reaction bottle, and the mass of the absorption liquid was weighed every 1 min during the absorption process, and the experiment was stopped after 30 min of absorption. SO per gram of ionic liquid 2 The saturated absorption is 0.64g / g.

Embodiment 2

[0028] Add 105.14g diethanolamine and 105g water in the flask, take 90g 4-methylphthalic acid in constant pressure dropping funnel according to the molar ratio of diethanolamine and 4-methylphthalic acid 2:1, slowly titrate at room temperature After the titration, the temperature was raised to 80°C and the reaction was completed for about 3 hours. The ionic liquid solution prepared by the reaction is dark yellow liquid with good fluidity.

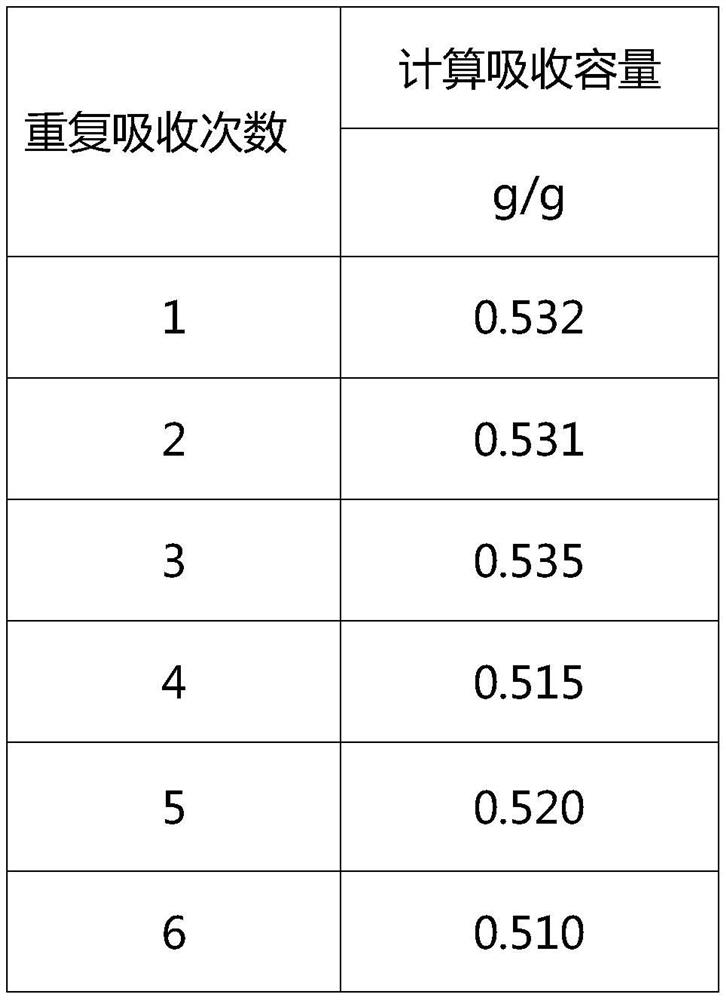

[0029] Mix and dilute the above-mentioned ionic liquid aqueous solution and water at a volume of 1:1, take 5ml of the diluted ionic liquid solution as an absorption liquid and put it in a reaction bottle, adjust the gas flow rate to 50ml / min, and dissolve the SO 2 The gas was connected to the reaction bottle, and the mass of the absorption liquid was weighed every 1 min during the absorption process, and the experiment was stopped after 30 min of absorption. SO per gram of ionic liquid 2 The saturated absorption is 0.54g / g.

Embodiment 3

[0031] Add 129.24g of n-octylamine and 130g of water into the flask, and take 86.09g of n-octylamine and o-cyclohexanedicarboxylic acid at a molar ratio of 2:1 in a constant pressure dropping funnel, and slowly titrate at room temperature After the titration, the temperature was raised to 80°C and the reaction was completed for about 3 hours. The ionic liquid solution prepared by the reaction is dark yellow liquid with good fluidity.

[0032] Mix and dilute the above-mentioned ionic liquid aqueous solution and water at a volume of 1:1, take 5ml of the diluted ionic liquid solution as an absorption liquid and put it in a reaction bottle, adjust the gas flow rate to 50ml / min, and dissolve the SO 2 The gas was connected to the reaction bottle, and the mass of the absorption liquid was weighed every 1 min during the absorption process, and the experiment was stopped after 30 min of absorption. SO per gram of ionic liquid 2 The saturated absorption is 0.60g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com