Brake bottom plate integrated axle housing assembly

A brake base plate and one-piece technology, applied in the direction of brakes, brake components, rolling resistance optimization, etc., can solve the problems of unfavorable axle housing weight reduction, axle housing weight increase, complex structure, etc., and achieve support strength that is beneficial and saves The effect of parts and structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

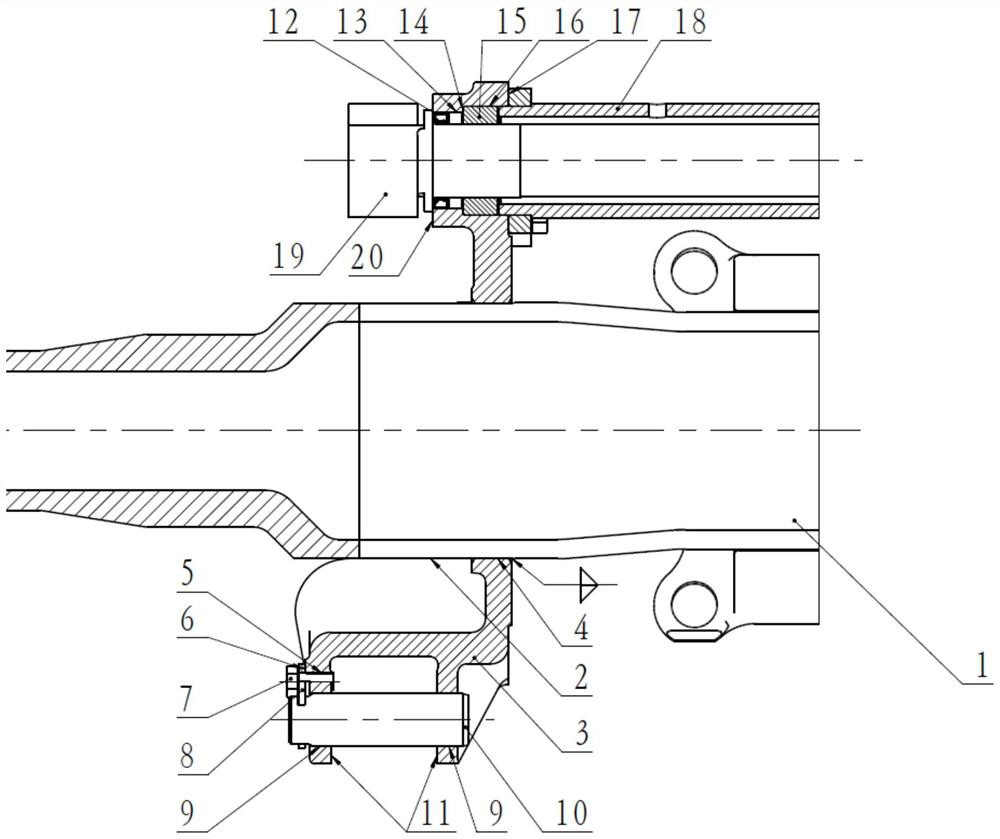

[0021] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

[0022] Such as figure 1 As shown, the present invention provides a brake floor integrated axle housing assembly, including an axle housing 1 and a brake base plate 3, the axle housing 1 is provided with a processed outer circle 2, and the processed outer circle 2 is located on the axle housing 1 Limiting annular protrusions at both ends; the brake base plate 3 is provided with a processed inner hole 4, which is located at the center of the brake base plate 3 and can cooperate with the processed outer circle 2. There are 4 sets of processed inner holes The outer circle 2 is processed, and both sides of the brake base plate 3 are connected with the axle housing 1 into one body through welding process.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com