Easy-to-adhere film and method for manufacturing the same, a polarizing plate, and an image display device

一种制造方法、薄膜的技术,应用在化学仪器和方法、光学、偏振元件等方向,能够解决显示特性降低、条纹状不均等问题,达到粘接性优异、不易粘连、不易光学坏点的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

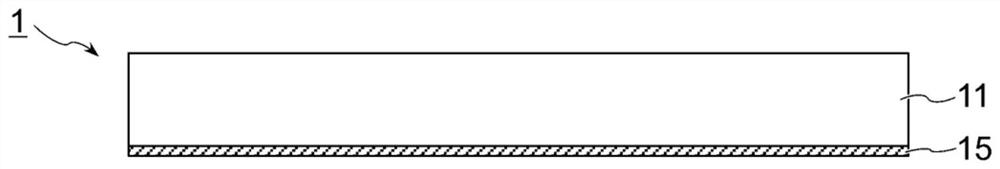

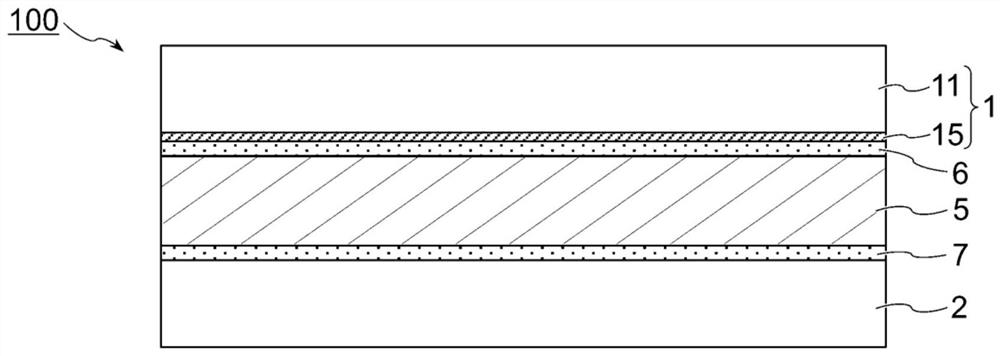

Embodiment 1

[0143] An easy-adhesive film was produced using a film production device equipped with a melt extrusion film forming device, a gravure coater, a tenter type simultaneous biaxial stretching device, and a winding device. As the acrylic resin, pellets of the same imidized MS resin (glass transition temperature: 120° C.) used in the production of “transparent protective film 1A” described in JP-A-2017-26939 Example were used. material. An acrylic resin was melt-extruded from a T-die to form a film with a thickness of 160 μm, and one side of the film was coated with the above-mentioned easy-adhesive composition with a wet thickness of about 9 μm by a gravure coater. In this case, an acrylic film with a thickness of 40 μm is provided with an easy-adhesive layer with a thickness of 50 nm on one side of the acrylic film by stretching to 2 times each in the longitudinal direction (MD) and the width direction (TD) by a simultaneous biaxial stretching tenter. Easy to bond film.

Embodiment 2~4 and comparative example 1、2

[0145] Except having changed the coating thickness of the easily bonding composition, it carried out similarly to Example 1, and obtained the easily bonding film. Table 2 shows the thickness (after stretching) of the easily bonding layer.

Embodiment 5、6 and comparative example 3~5

[0147] The furnace temperature (stretching temperature) at the time of tenter stretching was changed as shown in Table 2. Except having changed stretching temperature, it carried out similarly to Example 1, and obtained the easily-adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com