Device for removing blockage of chlorine spray gun of fused salt chlorination furnace

A molten salt chlorination furnace, chlorine gas technology, applied in injection devices, titanium tetrachloride, titanium halide and other directions, can solve the problems of easy occurrence of danger, time-consuming and laborious, and achieve the effect of avoiding potential safety hazards and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

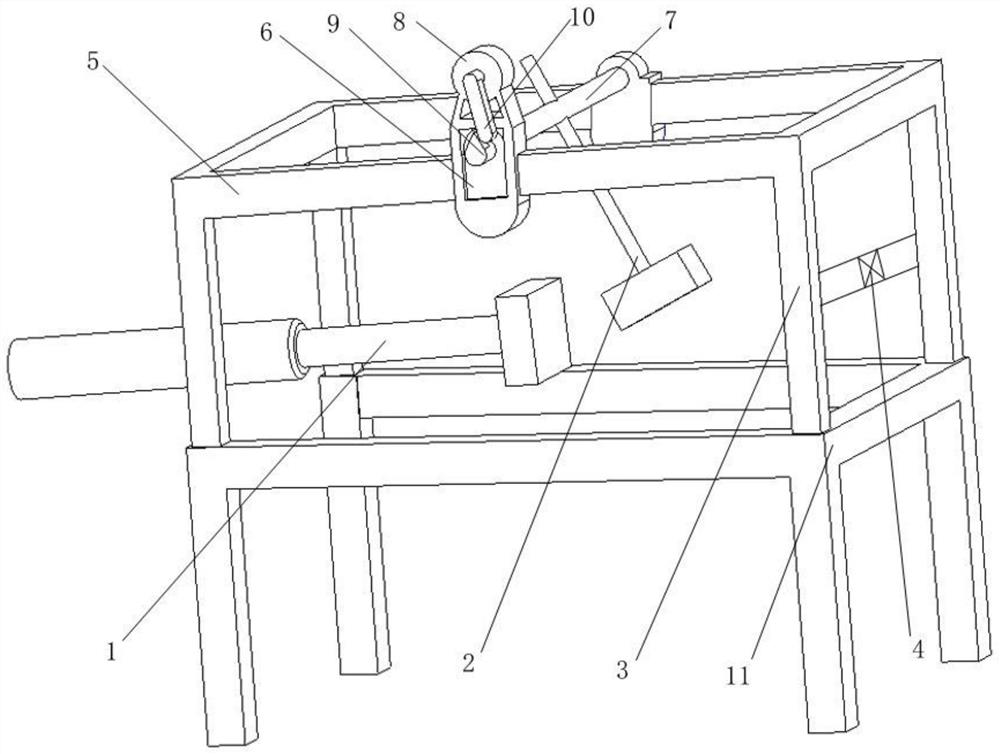

[0024] A device for dredging a chlorine spray gun of a molten salt chlorination furnace, comprising: a needle 1 and an iron hammer 2 for beating the needle 1, and a support frame 3 provided with a lateral movement device, the A swing device is fixed on the lateral moving device, the hammer 2 is arranged on the swing device, and the supporting frame 3 is provided with an inductive detector 4 for detecting the movement of the poking needle 1 .

[0025] The support frame 3 includes beams 5 on both sides of the top, the lateral movement device is arranged on the beam 5, and the lateral movement device includes a guide rail arranged on the side of the beam 5 and a slide block 6 matched with the guide rail. The swinging device is fixed on the slider 6, and the slider 6 is fixedly connected with a transverse motor.

[0026] Described oscillating device comprises transmission shaft 7 and rotating motor 8, and described rotating motor 8 is fixedly arranged on the top of lateral movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com