Tire transmission efficient ore washer

A technology of ore washing machine and tires, which is applied in the field of ore washing machines, can solve the problems of power consumption, support seat falling off, and low efficiency at the same time, and achieve the effects of increasing the spraying range, accelerating cleaning efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

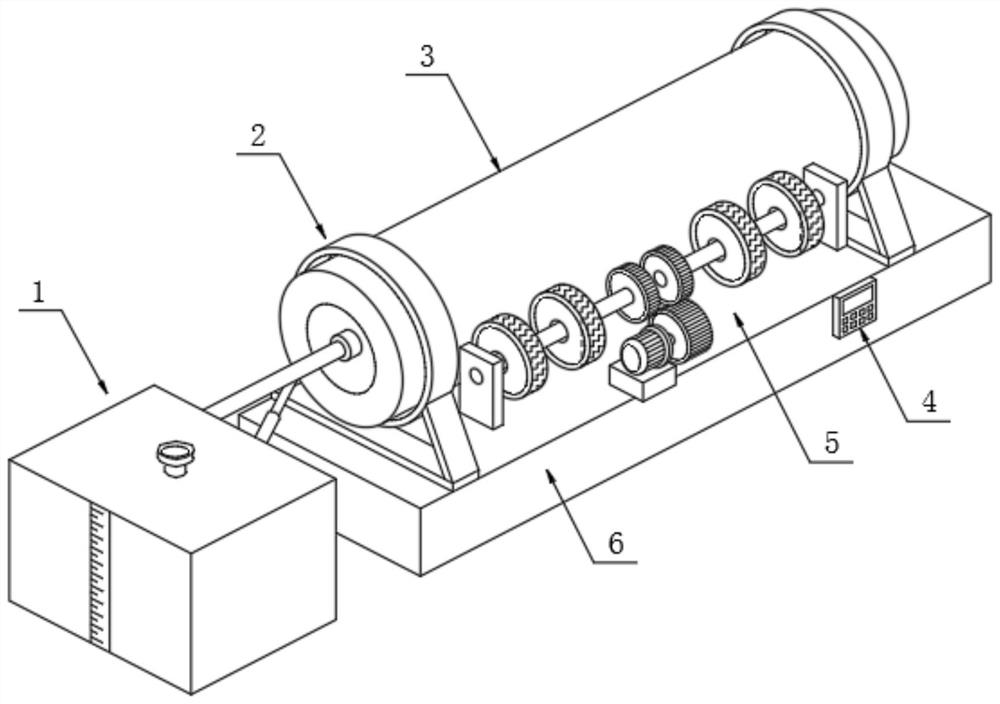

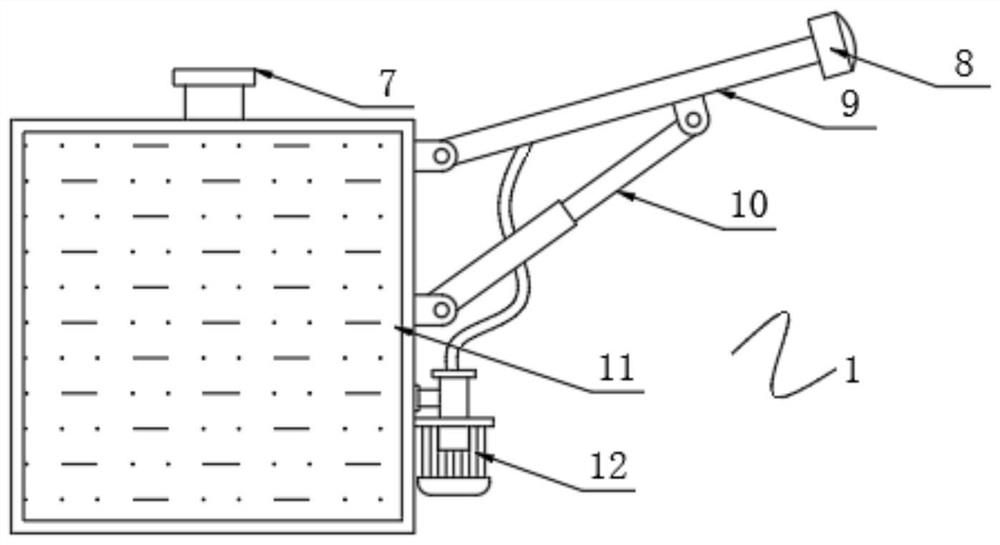

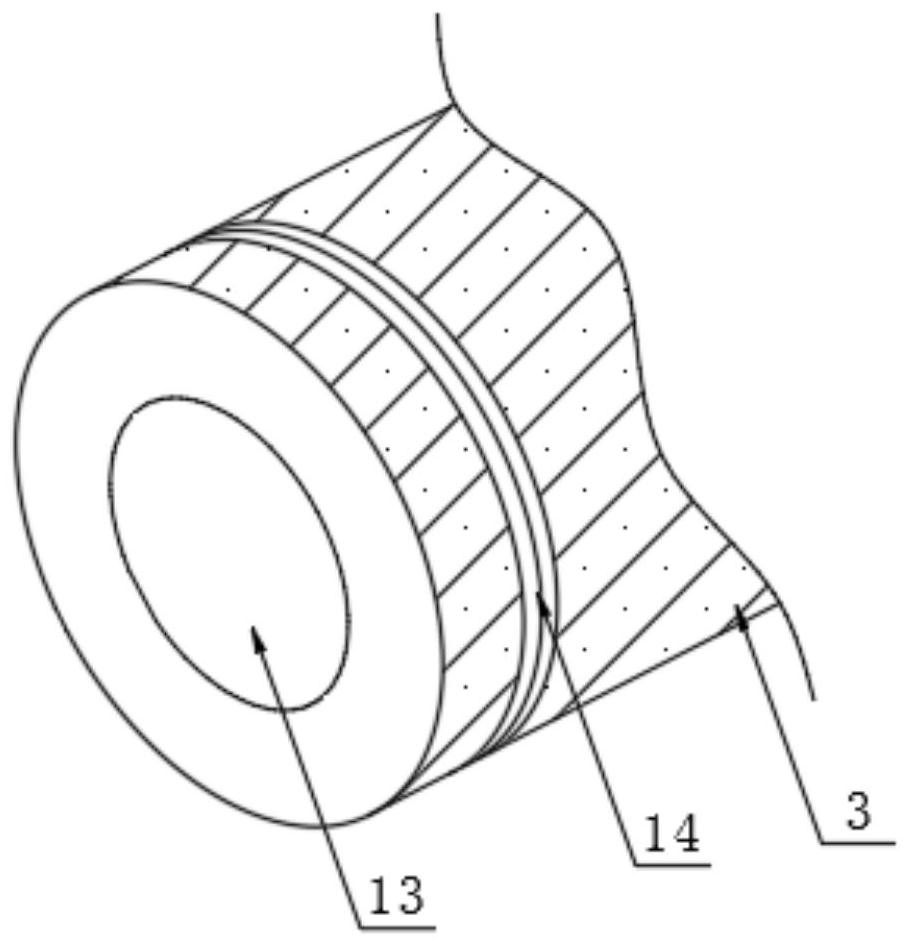

[0025] see Figure 1~6 , in an embodiment of the present invention, a tire-driven high-efficiency ore washing machine includes a main body 3 of the ore washing machine, a support seat 6 installed under the main body 3 of the ore washing machine, and a material injection set at the two ports of the main body 3 of the ore washing machine. port 13, a control switch 4 is fixedly connected to the front surface of the support base 6, and a storage battery is fixedly connected to the rear surface of the support base 6, a DKC-Y110 controller is installed inside the control switch 4, and a The sprinkler assembly 1, the sprinkler assembly 1 includes a water injection port 7, a sprinkler head 8, a connecting pipe 9, an electric push rod 10, a water storage tank 11 and a water pump 12, and one side of the water storage tank 11 is movably connected with a connecting pipe from top to bottom 9 and an electric push rod 10, and a water injection port 7 is fixedly connected to the center of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com