High-power single-resonant-cavity air-cooled laser light source suitable for laser deicing

A laser light source, high-power technology, applied in the direction of laser cooling device, structure/shape of optical resonator, laser, etc., can solve the difficulty of chemical deicing chemical agent spilling and smearing, the difficulty of chemical agent spilling and smearing, line The cable contact area is small and other problems, and the effect of high deicing efficiency, moderate output power density and low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

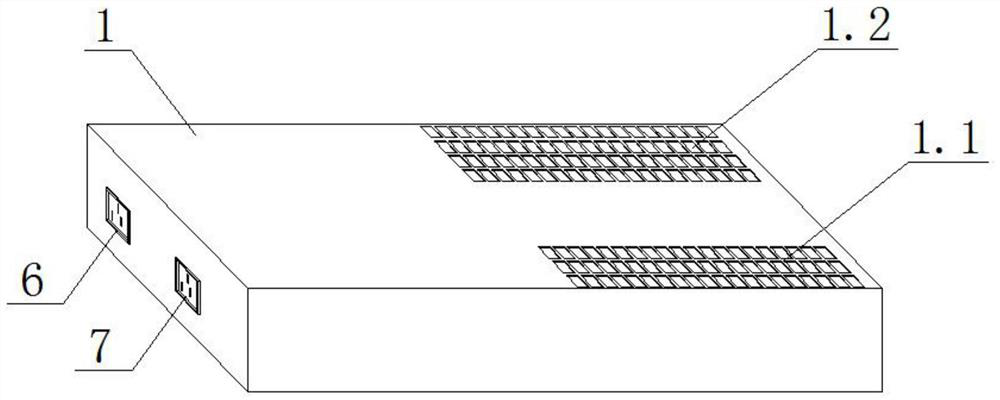

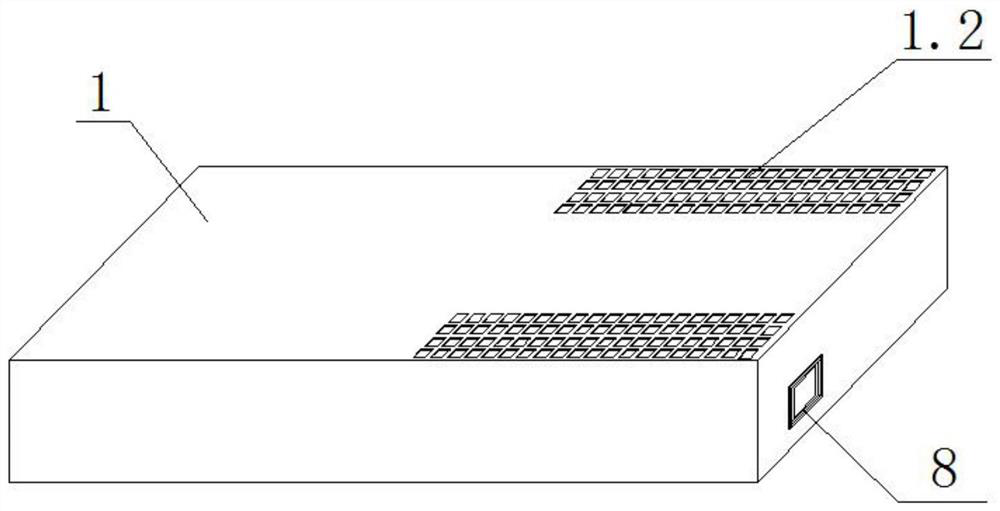

[0029] refer to figure 1 and figure 2 As shown, a high-power single-cavity air-cooled laser light source suitable for laser deicing provided by the present invention includes a light source housing 1, and a fixed substrate 2, an AC-DC conversion power supply 3, a DC The energy storage power supply 4 and the laser generating module 5 are provided with an AC-DC conversion power supply interface 6 , a DC energy storage power supply charging interface 7 and a laser light source control interface 8 outside the light source housing 1 .

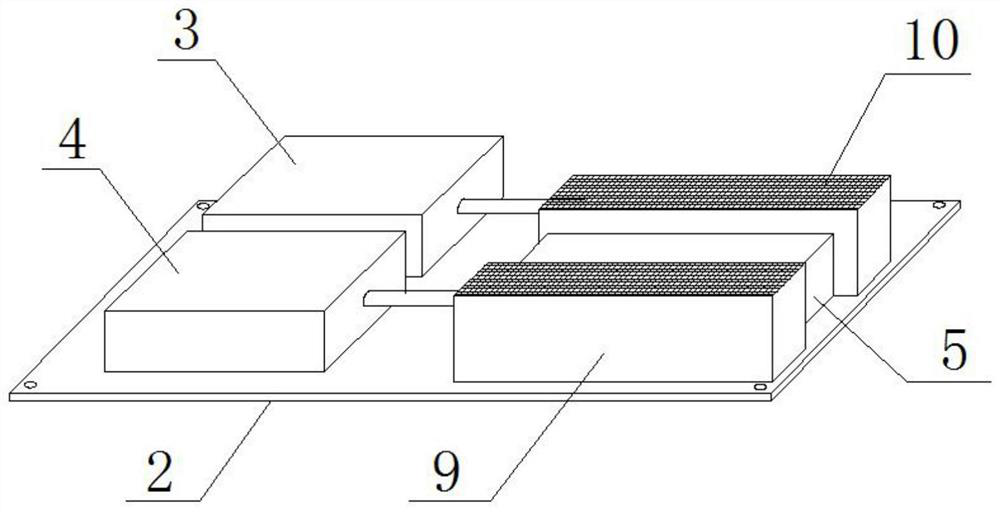

[0030] Specifically, as a specific embodiment of the present invention: see image 3 and Figure 4 As shown, the AC-DC conversion power supply 3, the DC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Gain coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com