Streamline tunnel type rotating fluid machine runner design and forming method

A fluid machinery, tunnel-type technology, applied in mechanical equipment, liquid fuel engines, non-variable-capacity engines, etc., can solve the problems of lack of depth, no mention of flow channel forming, and less research on streamlined tunnel-type rotating machinery. Achieve the effect of smooth transition of curvature, smooth curvature change, and small flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

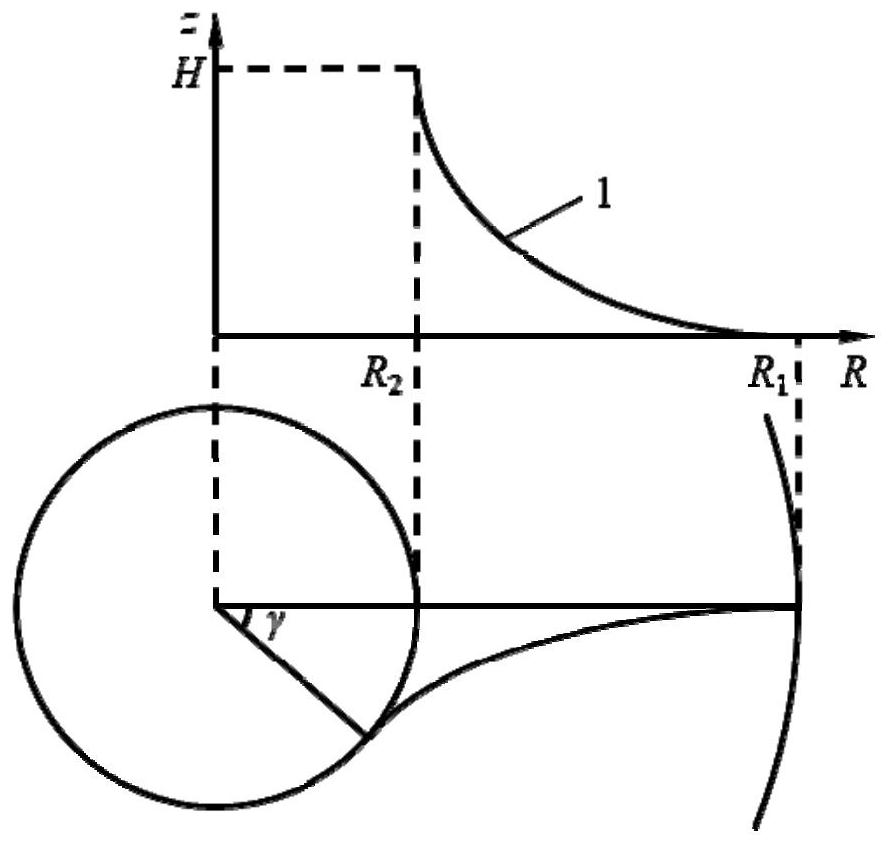

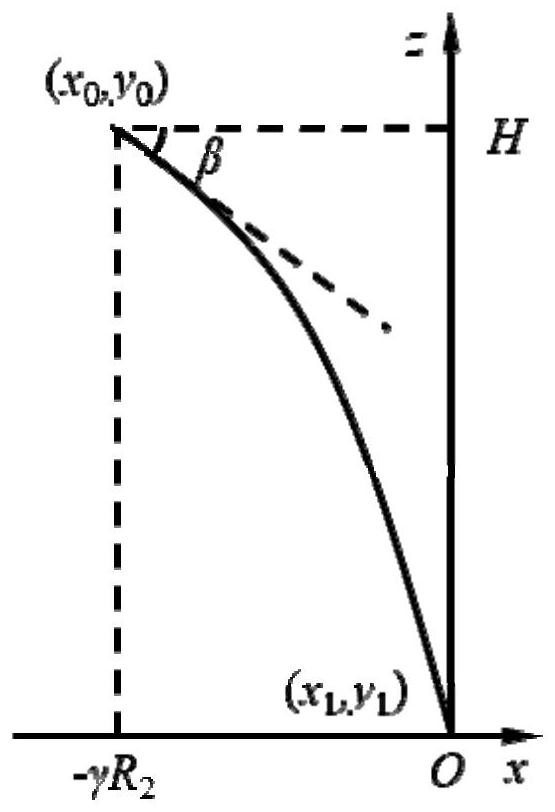

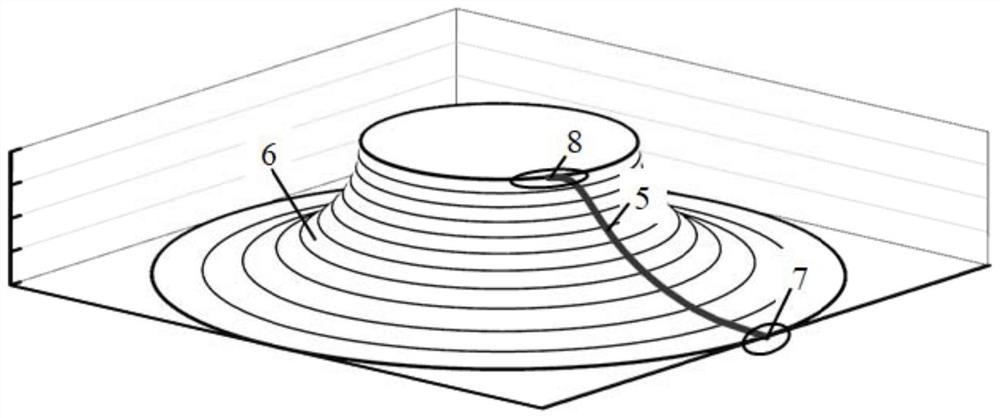

[0031] Such as Figure 1-Figure 5 As shown, the present invention provides a flow channel design and forming method of a streamline tunnel type rotary fluid machine, and the design and forming method includes the following steps:

[0032] S1: Constraint parameters obtained from one-dimensional design include: the radius of the two ends of the centerline far end point 7 and the centerline near end point 8 of the flow channel, and the structure at the two ends of the centerline far end point 7 and the centerline near end point 8 Angle, and assuming the envelope angle of the flow channel, the axial (z-axis direction) distance between the far end point 7 of the center line and the near end point 8 of the center line;

[0033] S2: Considering the near-central point 8 on the center line of the runner, which is closer to the axis, for a single-stage centripetal turbine or centrifugal compressor, the absolute velocity at the near-end point 8 of the centerline is generally close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com