Wind power generation device for high-temperature flue gas mechanical cooler, and power generation method

A technology of wind power generation device and high temperature flue gas, which is applied to wind turbines, wind power generation, wind turbines and other directions at right angles to the wind direction to achieve the effect of zero energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

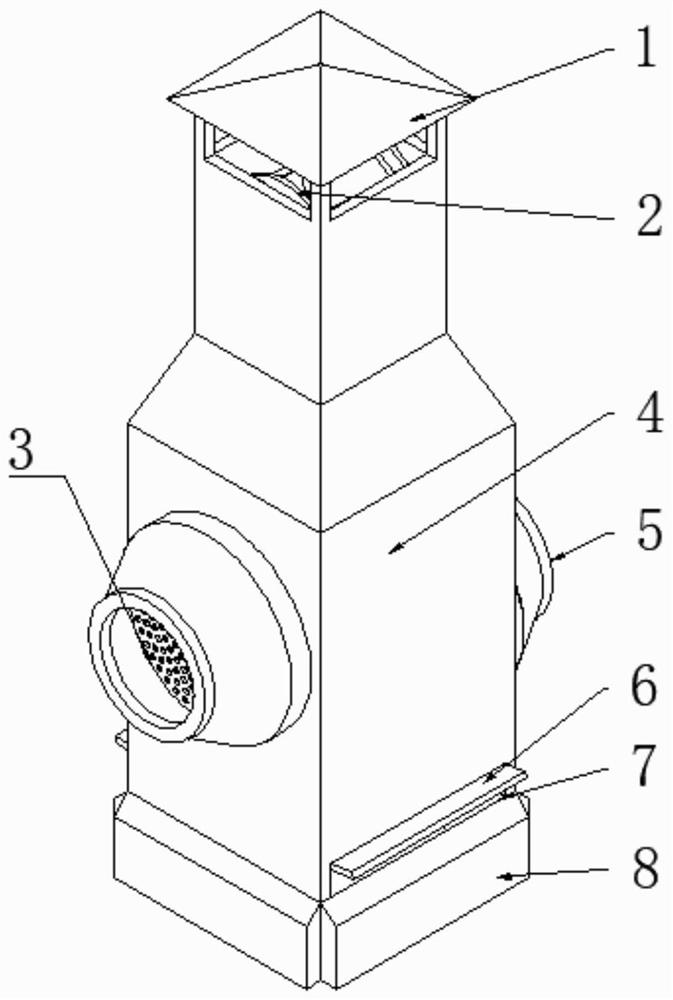

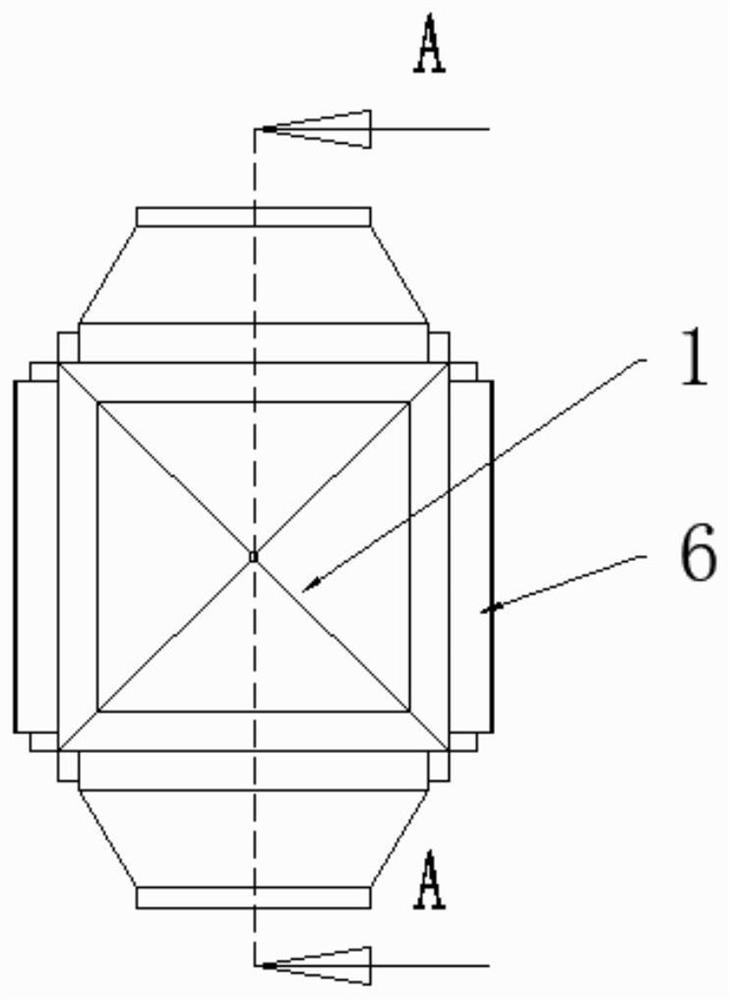

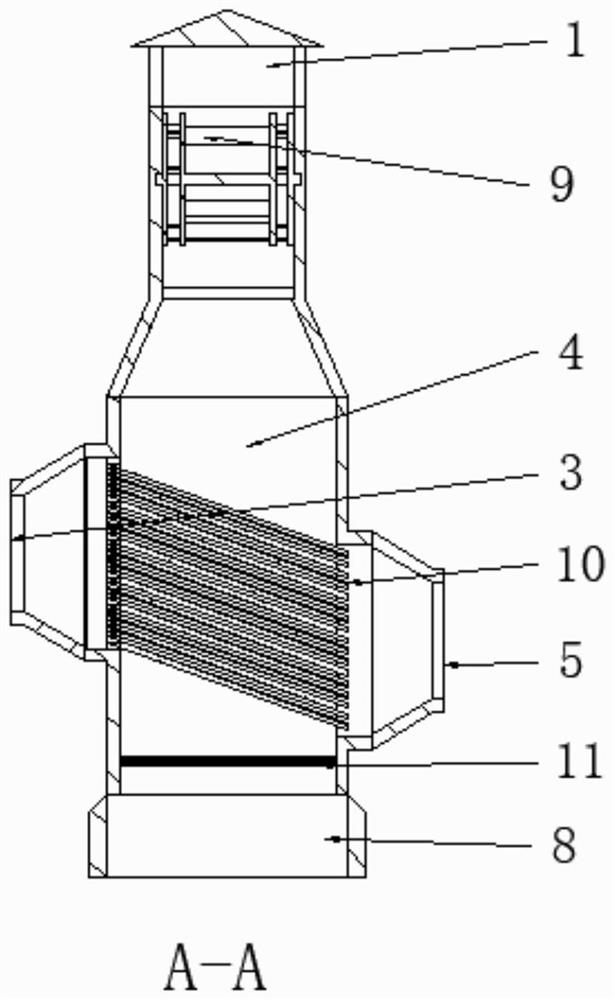

[0019] Embodiment 1 is basically as attached Figure 1~3 Shown: a wind power generation device of a high-temperature flue gas mechanical cooler, including a base 8, a box 4 and a heat exchanger, the bottom of the box 4 is connected to the base 8, and the top of the box 4 is connected to the chimney 1 , a vertical axis wind generator 2 is provided on the box body 4 near the chimney 1, a cold air inlet 7 is provided on the box body 4 near the base 8, and a heat exchanger 10 is arranged on the box body 4, and is located in the cold wind Above the inlet 7, the heat exchanger includes a high-temperature flue gas inlet 5, a heat exchange tube 10, and a high-temperature flue gas outlet 3. The high-temperature flue gas inlet 5 and the high-temperature flue gas outlet 3 are respectively located on opposite sides of the box body 4. 10 is arranged obliquely downward, and the two ends of the heat exchange tube 10 are connected to the high-temperature flue gas inlet 5 and the high-temperat...

Embodiment 2

[0022] The difference between Embodiment 2 and Embodiment 1 is that a plurality of vertical axis wind generators 2 are provided, and the plurality of vertical axis wind generators 2 are installed sequentially from top to bottom, and only one generator is provided.

Embodiment 3

[0023] The difference between embodiment 3 and embodiment 1 is that the heat exchange tube 10 is arranged obliquely downward, and the inclination angle is 30°.

[0024] Through the wind power generation device of the above-mentioned high-temperature flue gas mechanical cooler, wind power generation can be carried out. The chimney 1 is rectangular or square. The height of the chimney 1 is at least 20 meters. The high-temperature flue gas inlet 5 enters the heat exchange tube 10, and the cold air enters from the cold air inlet 7 under the action of the chimney 1, flows through the surface of the heat exchange tube 10 and contacts the heat exchange tube 10 to cool the high-temperature flue gas, The cooled high-temperature flue gas is discharged from the high-temperature flue gas outlet 3, and the temperature of the heated cold air rises to become hot air, which flows upwards and reaches the vertical axis wind turbine 2 so that the vertical axis wind turbine 2 The combined wind wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com