Anti-silting sewage pump station

A sewage pumping station, anti-silting technology, applied in water/sewage treatment, water/sludge/sewage treatment, water supply equipment, etc., can solve problems such as accumulation, environmental impact, filter damage, etc., to prolong service life, Effect of preventing deposition and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

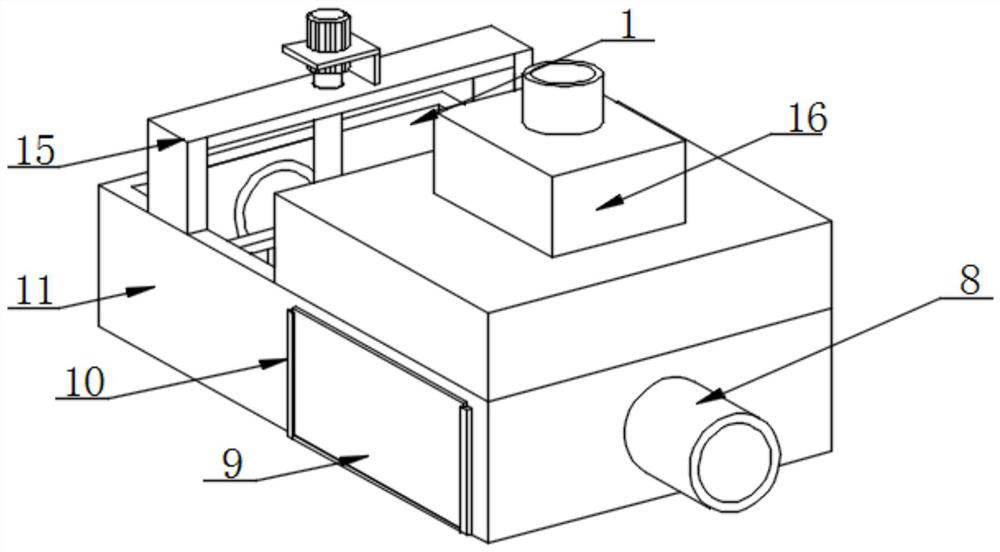

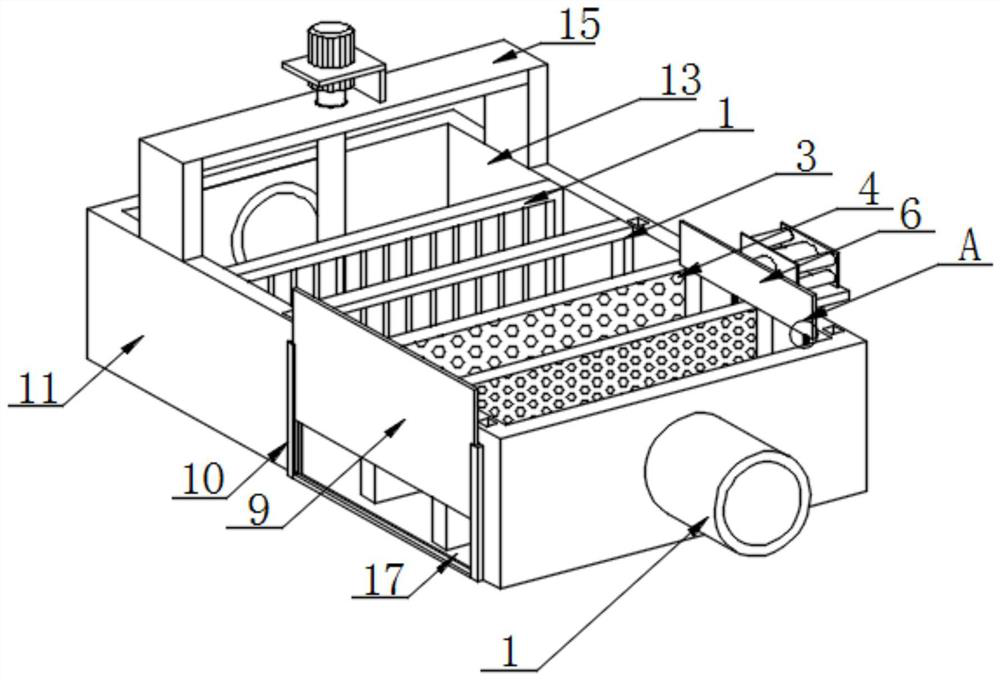

[0028] see Figure 1-8 , in an embodiment of the present invention, an anti-silting sewage pumping station includes a sump 11, and the inside of the sump 11 is respectively provided with a crushing chamber 1 and a filtering chamber 5 from left to right, and the crushing chamber 1 and the filtering chamber 5 pass through Partition plate 3 separates, and the inside of crushing chamber 1 is equipped with speed-reducing plate 13, and the inside of speed-reducing plate 13 is provided with speed-reducing rod 2, and the upper surface of sump 11 is fixedly installed with crushing assembly 15 above crushing chamber 1, The crushing assembly 15 comprises a crushing motor 151, a support 152, a support plate 153, a connecting rod 154, a crushing blade 155, a rotating rod 156 and a spiral blade 157, the upper surface of the support plate 153 is fixedly equipped with a support 152, and the inside of the support 152 is provided with a Motor 151, the driving end of pulverizing motor 151 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com