Printed electronic ink-jet printer

An inkjet printer and electronic technology, applied in typewriters, printing devices, printed circuits, etc., can solve the problems of poor efficiency, inability to match substrate flexibility and adaptability, etc., to improve work efficiency, print coherently and quickly, increase The effect of great flexibility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

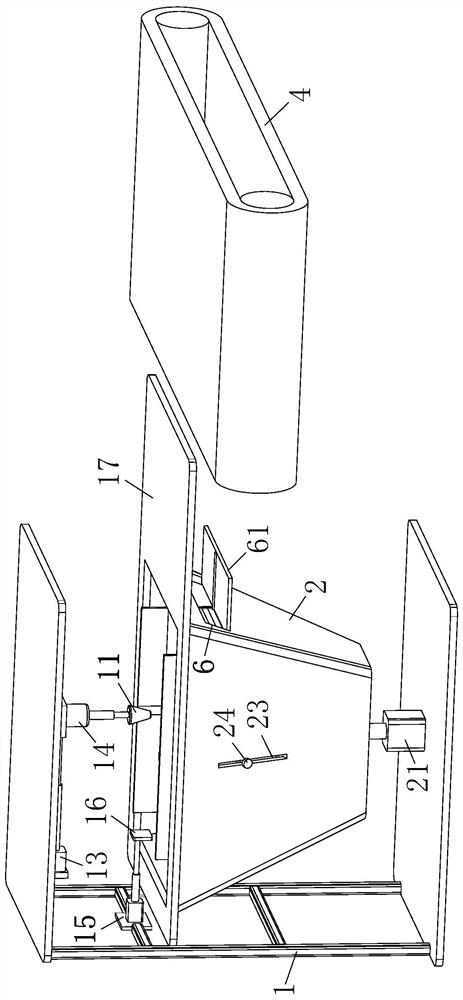

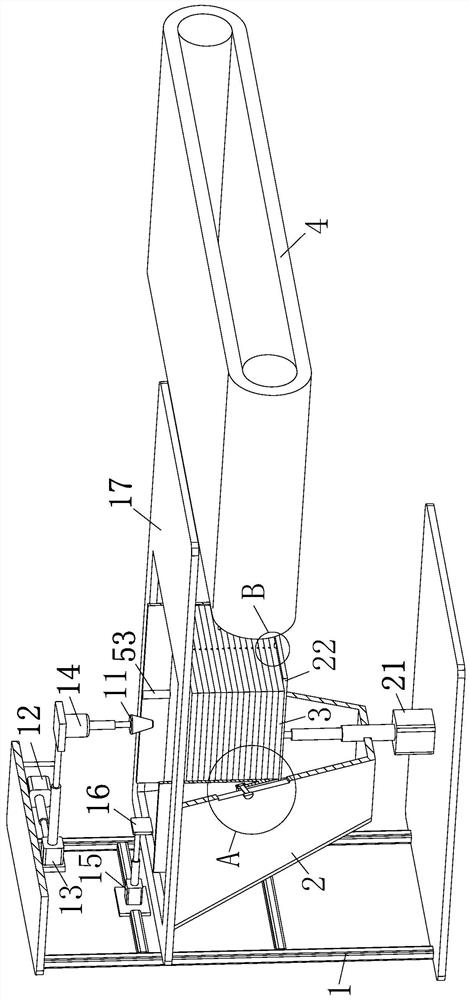

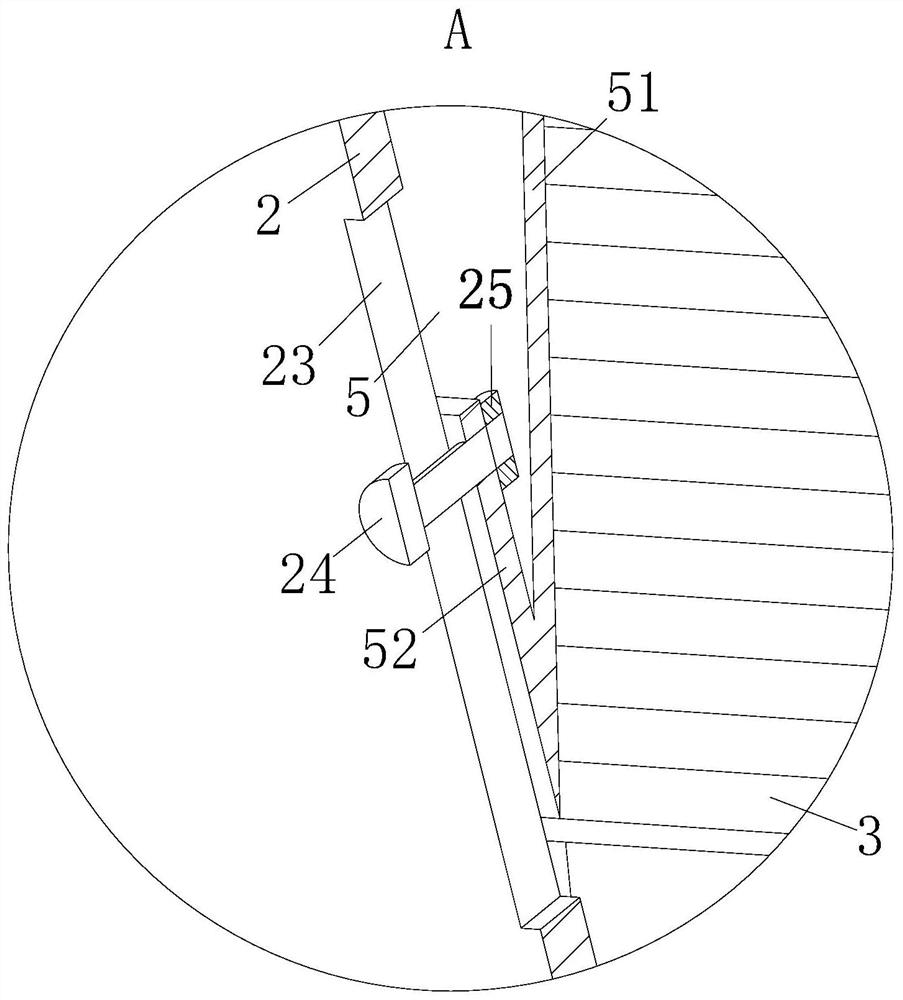

[0026] As an embodiment of the present invention, the side of the positioning chamber 2 corresponding to the side of the drive push rod 15 is symmetrically provided with a sliding groove 23, and the side of the positioning chamber 2 corresponding to the sliding groove 23 is provided with a bent type Sliding plate 5, described sliding plate 5 is made up of vertical positioning plate 51 and inclined adjusting plate 52, the side wall of described adjusting plate 52 fits with the inner wall of positioning chamber 2 at chute 23, and described chute 23 Internal sliding connection is provided with fastening bolt 24, and the inner end of described fastening bolt 24 is screwed with fastening nut 25 through adjusting plate 52; Slider 5 is set on the side of positioning cavity 2, so that the slide plate 5 in the initial state is positioned at the top position of chute 23, prevents substrate 3 from being placed on the inside of positioning cavity 2, and it is hindered, and when substrate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com