A processing device and processing method suitable for inverter shell assembly

A processing device and inverter technology, which is applied to workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problem of restricting the preparation efficiency of the inverter casing, affecting the preparation cost and assembly efficiency of the inverter casing. Low and other problems, to achieve the effect of reliable locking, reliable pressing, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

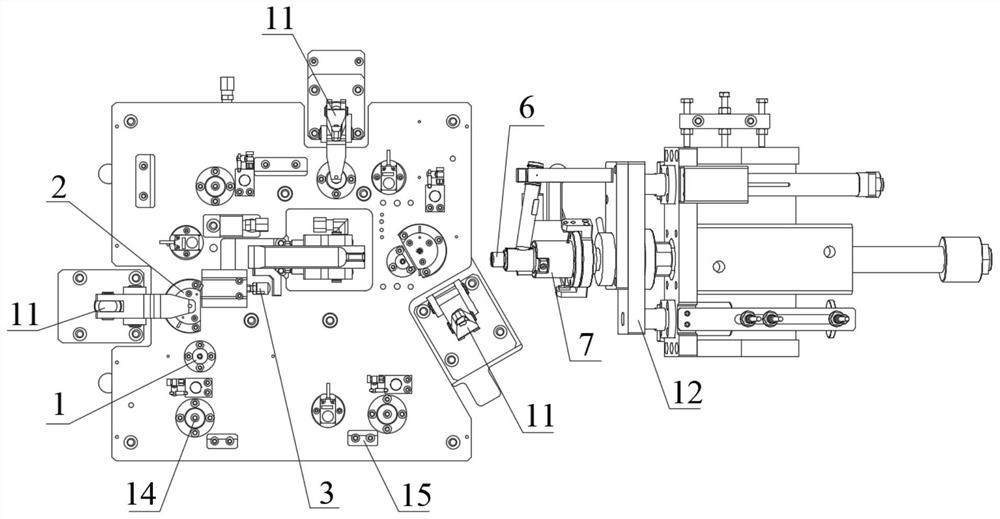

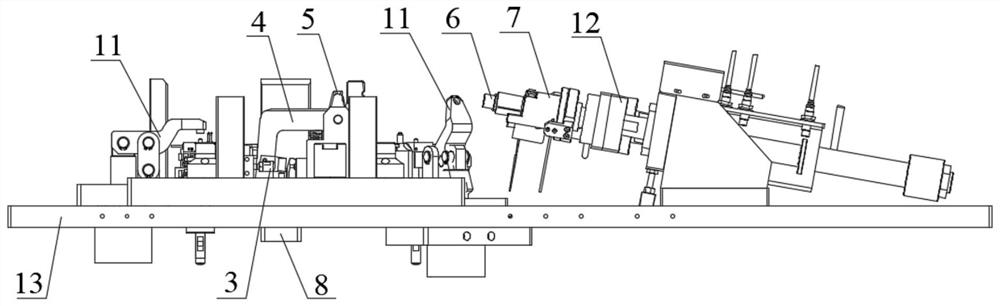

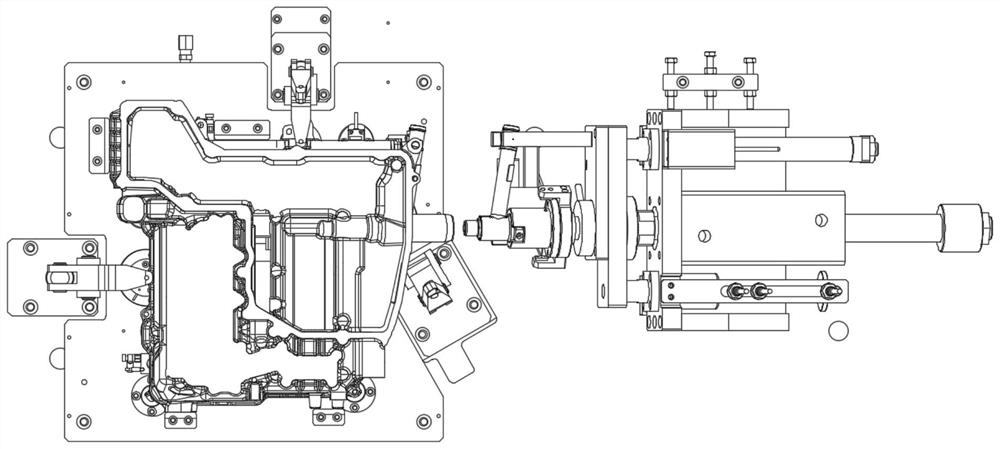

[0051] see Figure 1~4 , the processing device suitable for inverter shell assembly in the preferred embodiment of the present invention includes a workbench 13, which is a plate-shaped structure, fixedly installed or detachably installed at the corresponding processing position, and used for inverter shell assembly. The corresponding placement, clamping and processing of the body. In a preferred embodiment, the assembly of the pin holes and the fittings of the inverter casing can be completed on the workbench 13, and the entire assembly process can roughly include the following steps: (1) Clamp the inverter casing on on the workbench 13; (2) install the pins in the corresponding pin holes on the processing end surface of the inverter housing; (3) assemble the pipe fittings at the corresponding positions on the inverter housing; (4) complete the assembly The inverter casing is removed from the workbench 13 to complete the assembly process.

[0052] Specifically, several posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com