A self-locking clamping device for automatic machining

A mechanical processing and self-locking clip technology, applied in the field of mechanical processing, can solve the problems of affecting processing, increasing the number of defective products, increasing the impact force and friction force, etc., to achieve the effect of convenient transportation, convenient reprocessing and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

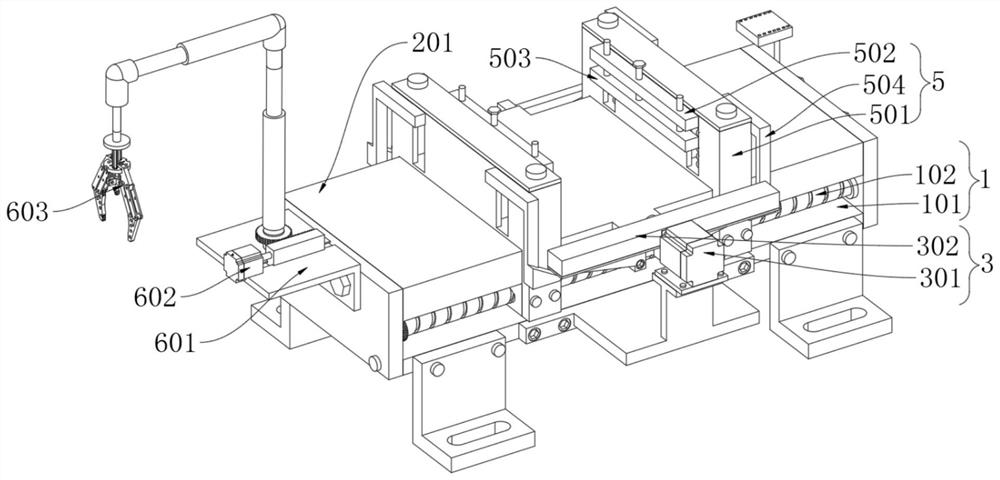

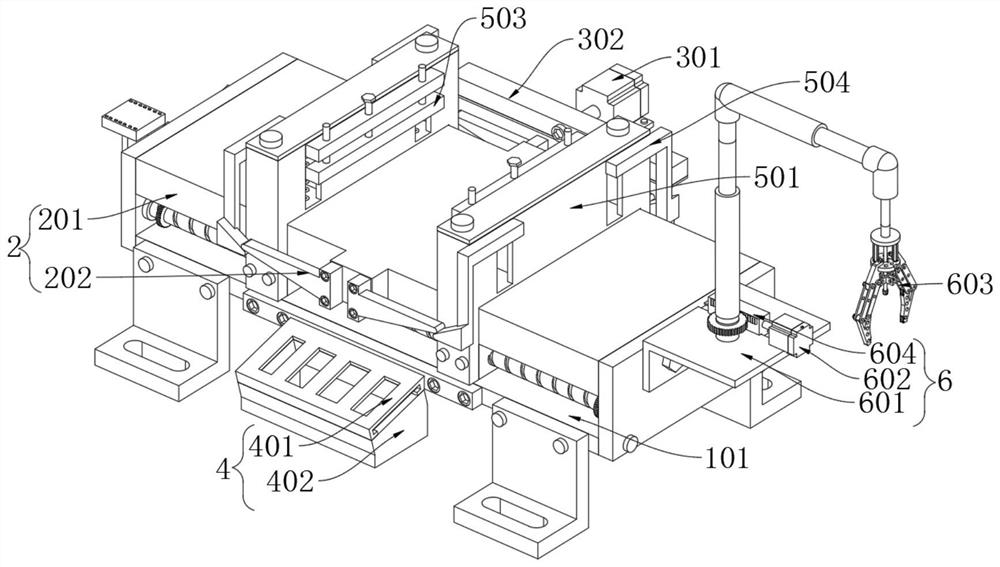

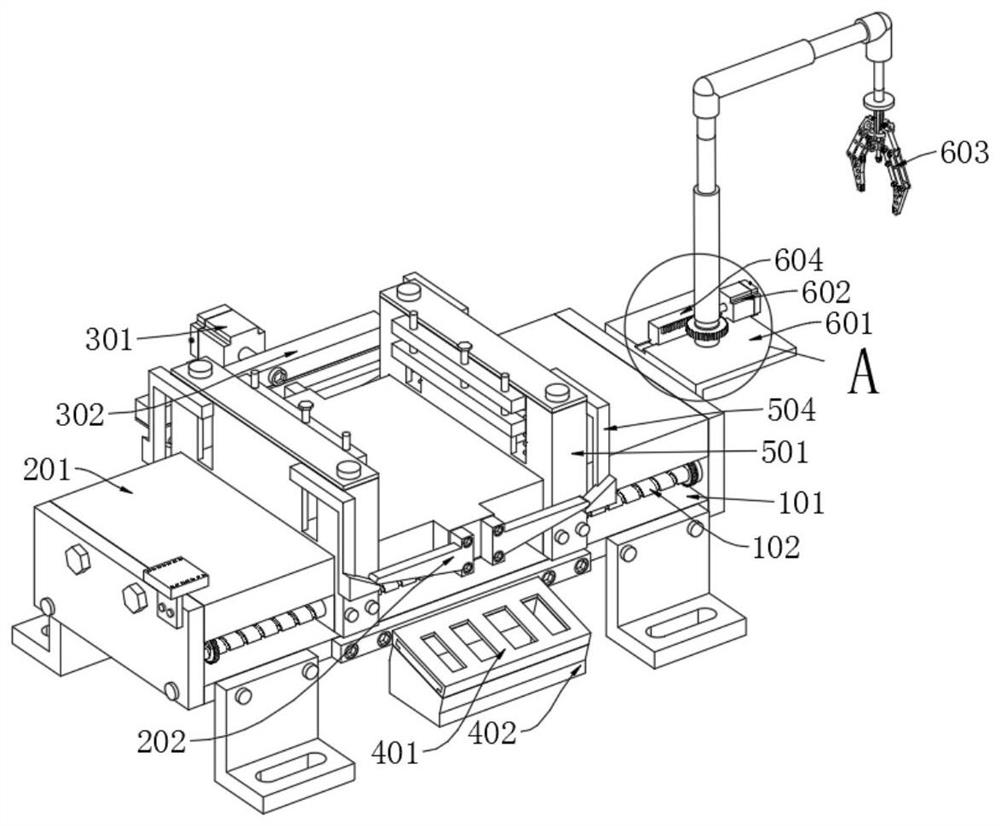

[0041] as attached figure 1 to the attached Figure 13 shown:

[0042] The invention provides a self-locking clamping device for automatic machining, comprising a fixing mechanism 1; the fixing mechanism 1 is provided with two sets of L-shaped fixing plates, and the fixing plates are provided with through holes for convenient connection with the body; The mechanism 1 includes a base 101, a threaded rod 102 and a servo motor 103. Two threaded rods 102 that are rotationally connected are symmetrically installed on the connecting plate of the rectangular base 101, and a gear is installed on the threaded rod 102; the middle position of the base 101 is installed There is a servo motor 103 with a gear, and the gear on the servo motor 103 meshes with the gear on the threaded rod 102, and the other ends of the two threaded rods 102 are connected by a chain, then when the servo motor 103 rotates, the two The two threaded rods 102 can rotate in the same direction, so that the threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com