Cleaning method of foreign matter on the tension roller of the rewinding unit

A cleaning method and tension roller technology, which are applied in the direction of keeping the roller equipment in an effective state, metal rolling, metal processing equipment, etc., can solve the problems of difficulty in cleaning foreign objects on the surface of the tension roller, affecting the quality and production efficiency, and insufficient cleaning space. , to achieve a significant overall effect, eliminate scratches, improve the effect of safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

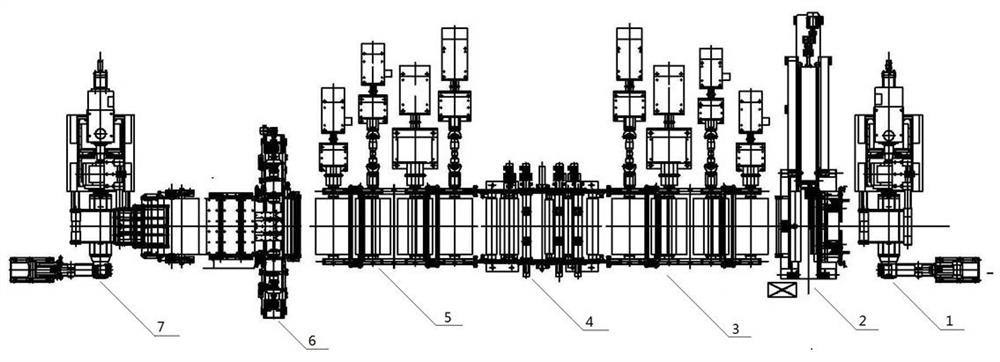

Image

Examples

Embodiment 1

[0022] The method for cleaning foreign matter on the tension roller of the rewinding unit includes the following specific steps:

[0023] ① Modify the uncoiling tension of uncoiler 1 and the coiling tension of coiler 7: increase the uncoiling tension setting to 6kg / mm2, reduce the coiling tension to 0.5kg / mm2, and ensure that the uncoiling tension value is greater than the coiling tension by 5 kg / mm2 , and then remove the tension in the process section to realize automatic reversing, which prevents strip deviation and scratches;

[0024] ②Open the disc shears 6 and cut the strip steel side wires: in the process of reversing, in order to prevent the disc shears 6 from reversing to cut the strip steel twice, open the disc shears frame, cut off the side wires, and start reversing;

[0025] ③Find out the position on the strip steel surface of the bulge embossing: find out the periodicity by finding the embossing position of the bulge on the inspection table, whether it is 3.14m, i...

Embodiment 2

[0031] The method for cleaning foreign matter on the tension roller of the rewinding unit includes the following specific steps:

[0032] ①Find out the position on the strip steel surface of the bulge embossing: find out the periodicity by finding the embossing position of the bulge on the inspection table, whether it is 3.14m, if it is determined to be 3.14m, confirm that it is the embossing of the tension roller bulge;

[0033] ②Mark the circle with chalk on the surface of the strip steel plate: After confirming that it is a tension roller bulge, confirm the embossed position of the bulge by drawing a circle with a water-based pen;

[0034] ③Use a hammer to open the hole at the circle: use a sharp hammer to open the circle;

[0035] ④Reversing the car to find the source of foreign matter on the roller surface: By considering the concave and convex of the tension roller, it is determined that the convex is 1, 4, 5, and 8# tension rollers, and the concave is 2, 3, 6, and 7# te...

Embodiment 3

[0038] The method for cleaning foreign matter on the tension roller of the rewinding unit includes the following specific steps:

[0039] ① Modify the uncoiling tension of uncoiler 1 and the coiling tension of coiler 7: increase the uncoiling tension setting to 6kg / mm 2 , take-up tension reduced to 0.5kg / mm 2 , to ensure that the uncoiling tension value is greater than the coiling tension by 5 kg / mm 2 , and then remove the tension in the process section to realize automatic reversing, so as to avoid the deviation and abrasion caused by the prevention of strip steel;

[0040] ②Find out the position on the strip steel surface of the bulge embossing: find out the periodicity by finding the embossing position of the bulge on the inspection table, whether it is 3.14m, if it is determined to be 3.14m, confirm it is the embossing of the tension roller bulge;

[0041] ③ Mark with a chalk circle on the surface of the strip steel plate: After confirming that it is a tension roller bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com