Raw material mixing equipment for making bread and pastries

A mixing equipment and pastry technology, which is applied in the field of pastry raw material mixing devices, can solve problems such as poor taste, uneven distribution of pastry ingredients, difficult pastry molding, etc., and achieve the effect of improving shock absorption, improving efficiency and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

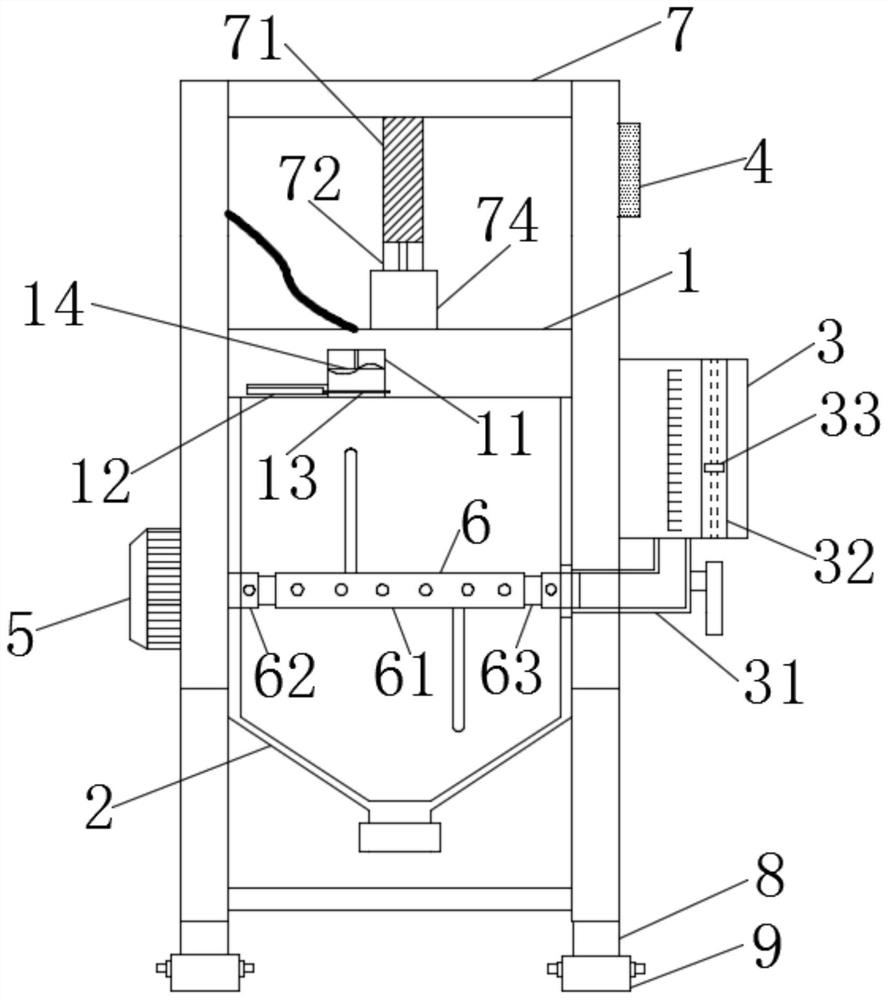

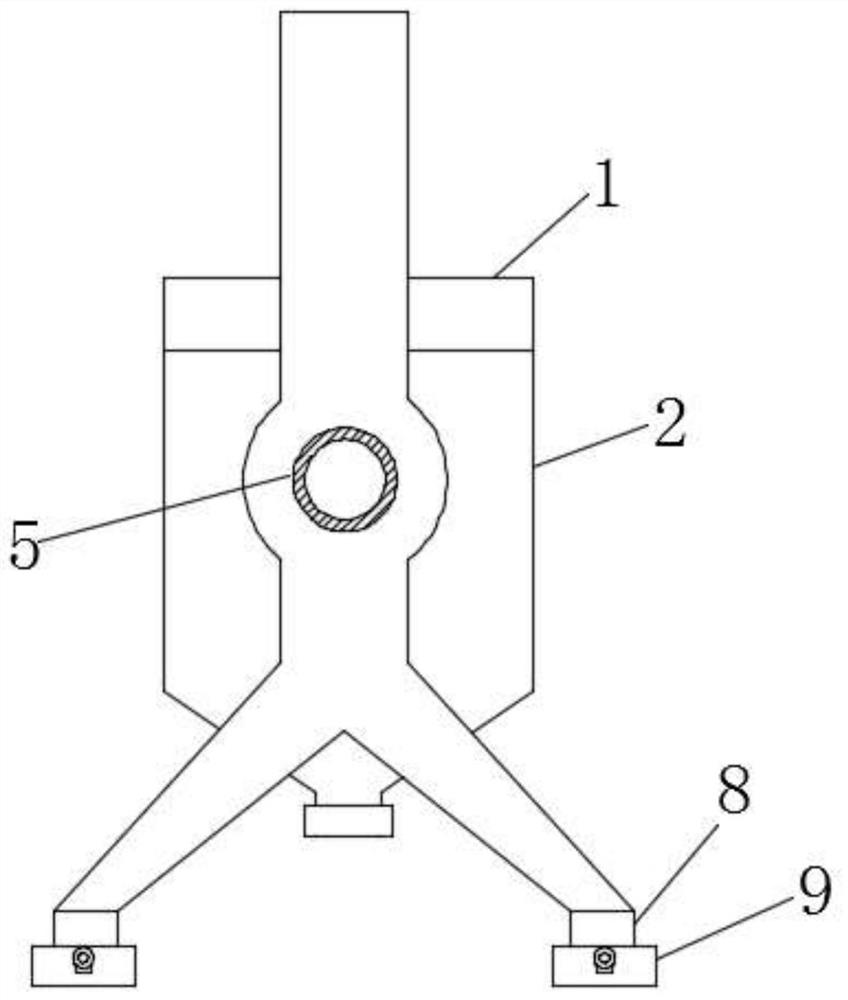

[0029] see Figure 1 to Figure 3 , the present invention provides a technical solution: a raw material mixing equipment for making bread and cakes, including a mixing tank and a support frame, the mixing tank includes a cover body 1, a bucket body 2, a water tank 3, an agitator and a control keyboard 4, The barrel body 2 is provided with a non-stick layer inner wall, the water adding tank 3 is provided with an outlet pipe 31, and the outlet pipe 31 is provided with a valve, and the water outlet of the water outlet pipe 31 is fixedly connected with the barrel wall of the barrel body 2, and the agitator includes a motor 5, a horizontal shaft 6 and the stirring rod, the output end of the motor 5 is connected to the left end of the horizontal shaft 6, the right end of the horizontal shaft 6 is connected to the barrel wall of the barrel body 2 through a bearing, and the right end of the horizontal shaft 6 is rotated and sealed with the inner wall of the water outlet pipe 31, and the...

Embodiment 2

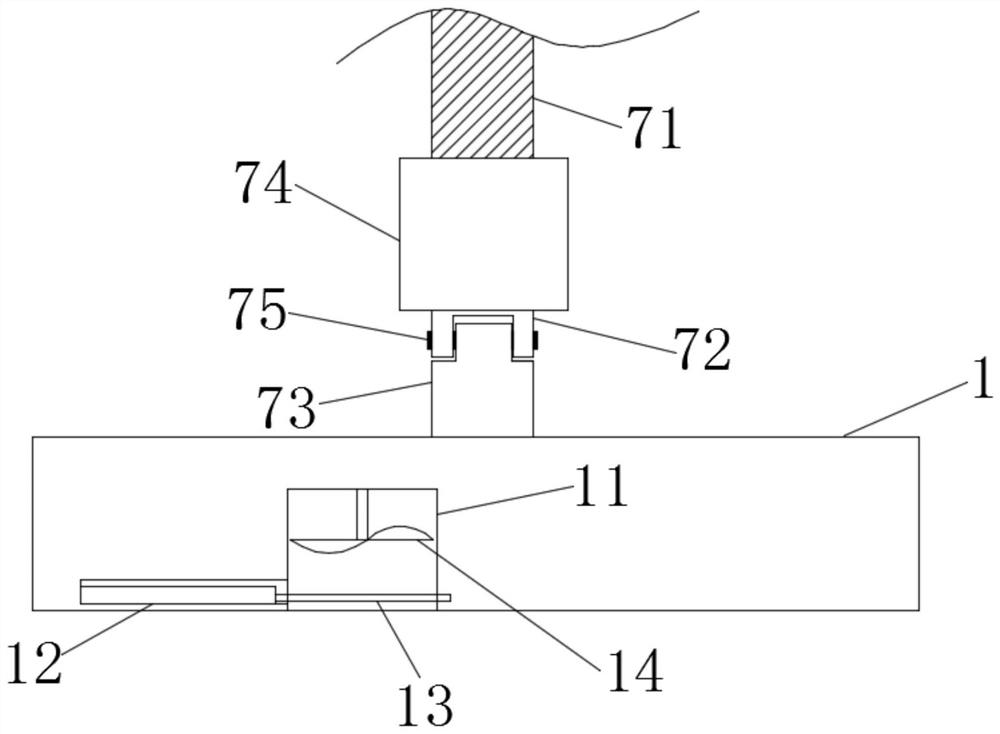

[0034] see figure 1 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a raw material mixing equipment for making bread and cakes, including a mixing tank and a support frame, the mixing tank includes a cover body 1, a bucket body 2, a water tank 3, an agitator and a control keyboard 4, The barrel body 2 is provided with a non-stick layer inner wall, the water adding tank 3 is provided with an outlet pipe 31, and the outlet pipe 31 is provided with a valve, and the water outlet of the water outlet pipe 31 is fixedly connected with the barrel wall of the barrel body 2, and the agitator includes a motor 5, a horizontal shaft 6 and the stirring rod, the output end of the motor 5 is connected to the left end of the horizontal shaft 6, the right end of the horizontal shaft 6 is connected to the barrel wall of the barrel body 2 through a bearing, and the right end of the horizontal shaft 6 is rotated and sealed with the inner wall of the wa...

Embodiment 3

[0039] see figure 1 and Figure 6 , the present invention provides a technical solution: a raw material mixing equipment for making bread and cakes, including a mixing tank and a support frame, the mixing tank includes a cover body 1, a bucket body 2, a water tank 3, an agitator and a control keyboard 4, The barrel body 2 is provided with a non-stick layer inner wall, the water adding tank 3 is provided with an outlet pipe 31, and the outlet pipe 31 is provided with a valve, and the water outlet of the water outlet pipe 31 is fixedly connected with the barrel wall of the barrel body 2, and the agitator includes a motor 5, a horizontal shaft 6 and the stirring rod, the output end of the motor 5 is connected to the left end of the horizontal shaft 6, the right end of the horizontal shaft 6 is connected to the barrel wall of the barrel body 2 through a bearing, and the right end of the horizontal shaft 6 is rotated and sealed with the inner wall of the water outlet pipe 31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com