Diaphragm and sounding device of a sounding device

A sounding device and rubber mixing technology, which can be used in sensors, electrical components, etc., can solve the problems of poor heat and cold resistance of thermoplastic resins, large product distortion, and small steric resistance, and achieve good overall performance and molding consistency. Good, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In the present invention, the method for preparing the diaphragm of the sound generating device includes the following steps: mixing the raw materials containing raw rubber and filler reinforcing agent to obtain the mixed rubber; taking the mixed rubber and molding it into Get the diaphragm.

[0053] The present invention also provides a sound generating device, which includes a magnetic circuit system and a vibration system that cooperate with each other, and the vibration system includes the above-mentioned diaphragm.

Embodiment 1

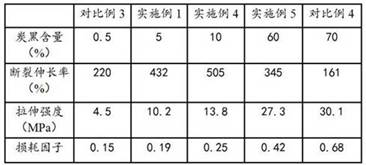

[0056] A vibrating membrane of a sounding device, the vibrating membrane comprises a layer of elastomer layer, wherein the elastomer layer is made of mixed rubber; and the raw materials of the vulcanization accelerator are obtained by mixing, wherein the raw rubber includes polysulfide rubber, and the particle diameter of the filler reinforcing agent is 10nm.

[0057] The filler reinforcing agent adopts carbon black; the content of the filler reinforcing agent is 5% of the total amount of the rubber compound.

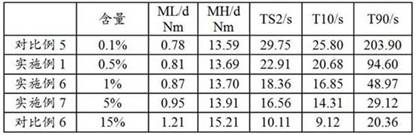

[0058] The vulcanizing agent adopts sulfur, and the vulcanizing accelerator adopts thiuram polysulfide; the content of the vulcanizing agent and the vulcanizing accelerator is 0.5% of the total amount of the rubber compound.

Embodiment 2

[0060] Based on Example 1, the only difference is that the filler reinforcing agent in Example 2 has a particle size of 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com