DC contactor and vehicle

A DC contactor and moving contact technology, which is applied to vehicle energy storage, vehicle components, relays, etc., can solve the problems of large size and high manufacturing cost of charging devices, and achieve the effects of simplifying structural design, reducing costs, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

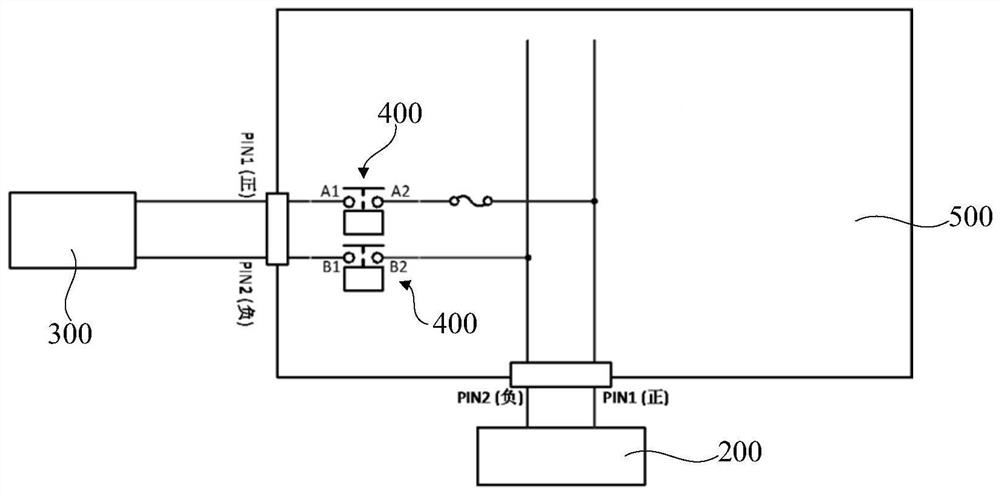

[0046] At present, electric vehicles, as environmental protection and energy-saving vehicles, are more and more widely used, and the fast charging contactors matched with them are also widely used. The DC contactor has become an important power distribution control device in the DC charging circuit of electric vehicles. In the current DC fast charging circuit, taking electric vehicles and DC fast charging devices as examples, see figure 1 As shown, the electric vehicle is provided with a PDU 500 and a high-voltage battery pack 200 connected to the PDU 500. The charging device of the electric vehicle has two terminals: PIN1 and PIN2, wherein PIN1 is a positive terminal, PIN2 is a negative terminal, and PIN1 terminal It is connected to the PDU 500 through a DC contactor 400 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com