Whole-process inventory level early warning and control method for iron and steel enterprise

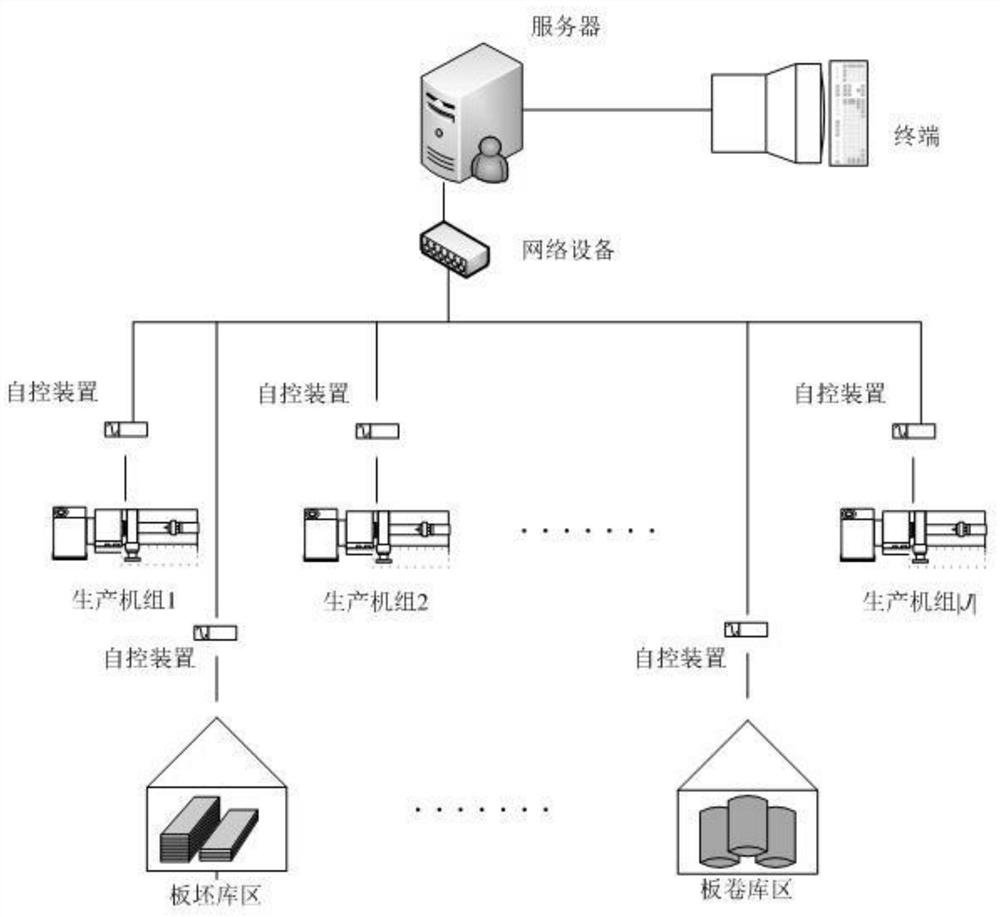

A control method and technology of the whole process, applied in logistics, manufacturing computing systems, instruments, etc., can solve problems such as difficulty in ensuring real-time performance, inability to adapt to the continuous operation mode of production actuators, and long response time for report execution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

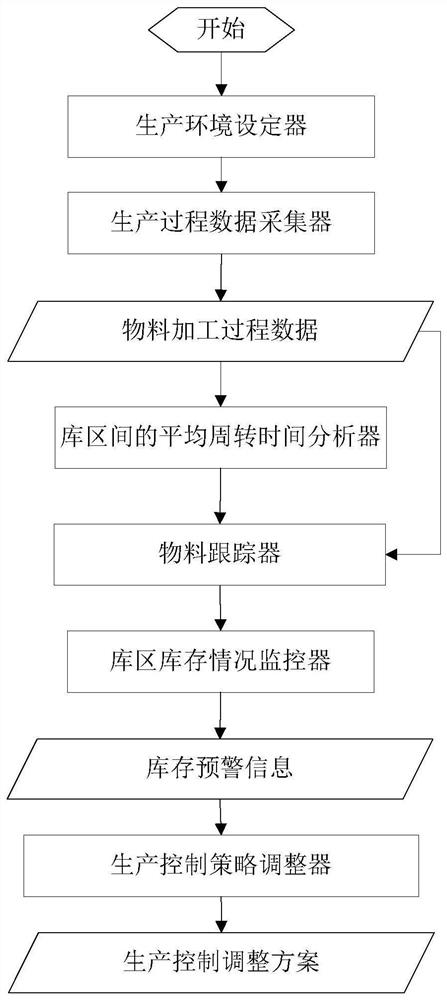

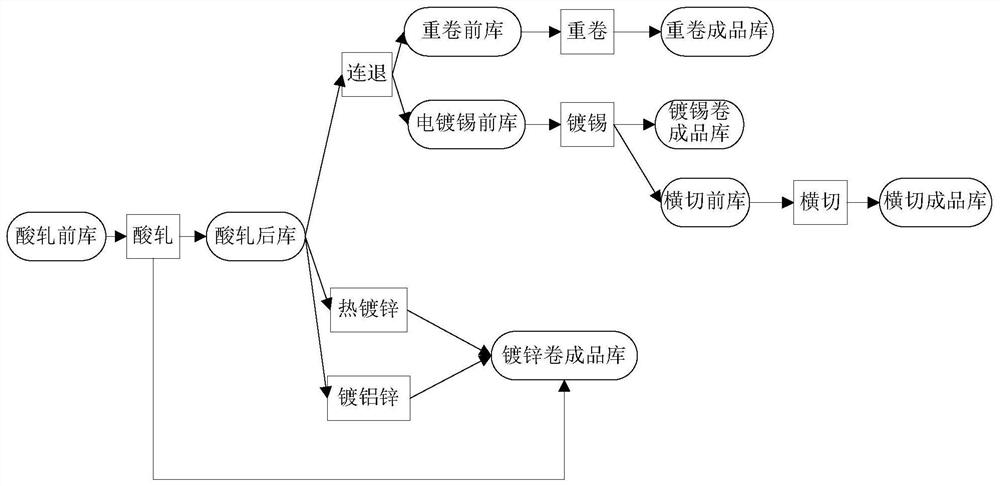

[0054] Embodiment 1: A method for early warning and control of inventory level in the whole process of iron and steel enterprises, said method comprising the following steps:

[0055] Step 1: Start the online production process data collector to collect historical production performance to build learning samples. The historical data is composed of the actual material type attributes after production, storage time, and storage time, specifically including: the material’s tapping mark , grade, packing method, thickness group distance, process path, route storage area, storage time, storage time;

[0056] Step 2: Establish an analyzer for the average turnover time of materials in the warehouse interval, use the online production process data collector to obtain information, and establish a regression analysis model for the turnover time of the LS-SVM warehouse interval. The regression analysis model for the turnover time of the warehouse interval specifically refers to According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com