Floor bearing capacity checking calculation and formwork removal construction method under concrete construction load effect

A technology of construction load and construction method, applied in the direction of floors, special data processing applications, building components, etc., can solve problems such as meager profits, losses, and large consumption of formwork and steel pipe supports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The present invention will be further described below in conjunction with accompanying drawing:

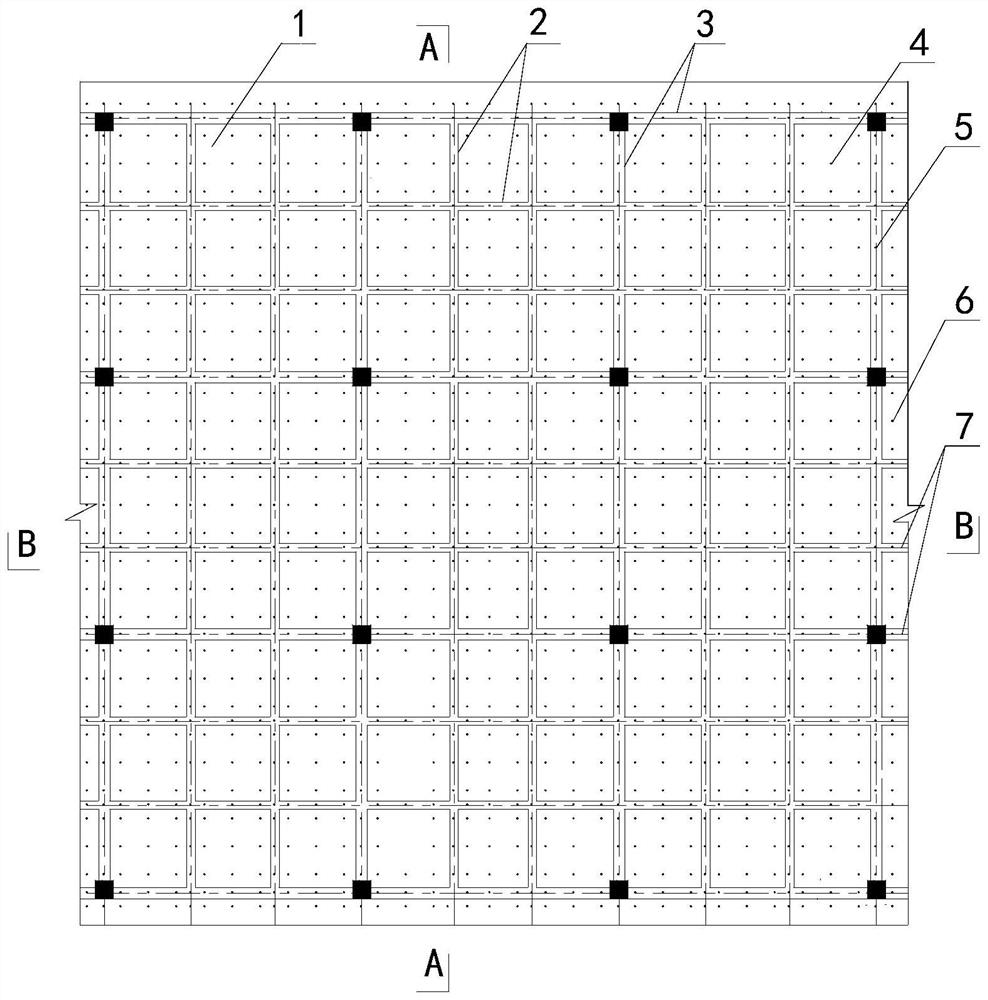

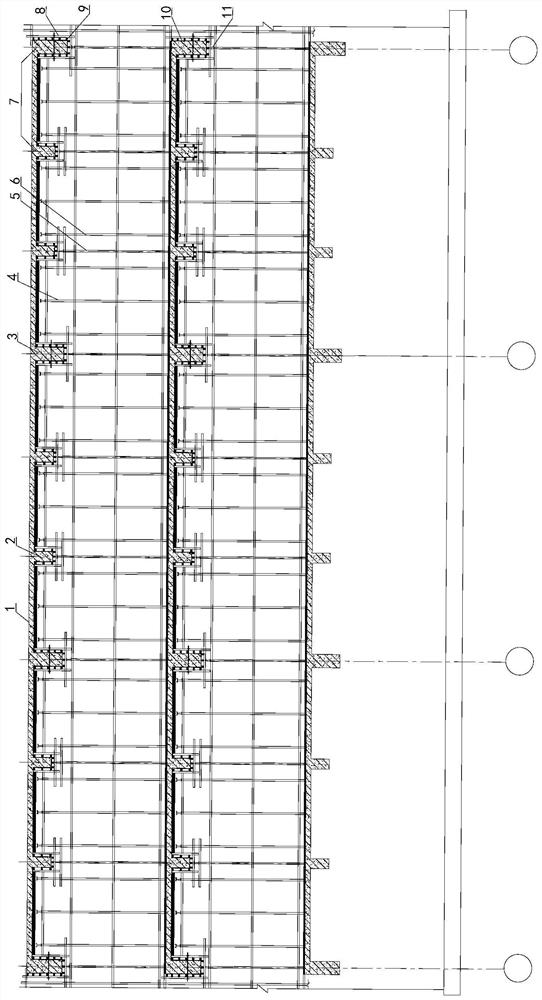

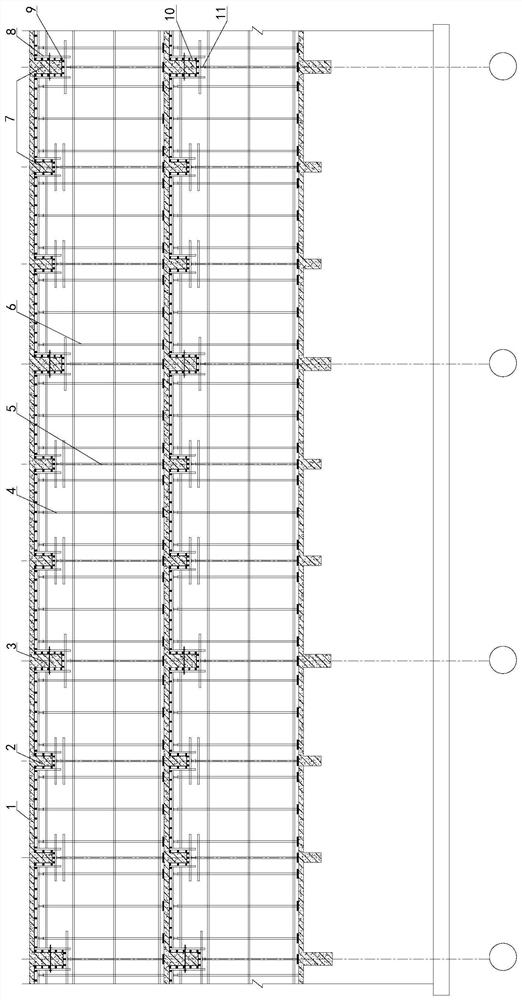

[0105] Such as figure 1 , figure 2 , image 3 Shown, under the action of concrete construction load of the present invention, floor bearing capacity checking and formwork removal construction method, take the following steps:

[0106] 1. Determine the object of floor bearing capacity checking:

[0107] On the structural diagram, select the cast-in-place slab 1, the secondary beam 2, and the frame beam 3 with smaller reinforcement cross-sections, and select the vertical and horizontal frame column grids as the checking objects of the floor bearing capacity;

[0108] 2. Determine the plan of the floor formwork support system:

[0109] 1. Material selection for formwork support system:

[0110] 1) Fastener-type steel pipe formwork support, composed of Q235B grade φ48mm×2.7mm~φ48mm×3.0mm steel pipe vertical pole, horizontal pole, beam bottom and beam side formwork main fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com