Flow distribution design method and device for micro evaporation tube type combustion chamber

A flow distribution and combustion chamber technology, applied in computer-aided design, calculation, special data processing applications, etc., can solve the problems of long calculation time and high simulation cost, and achieve the effect of alleviating the long calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

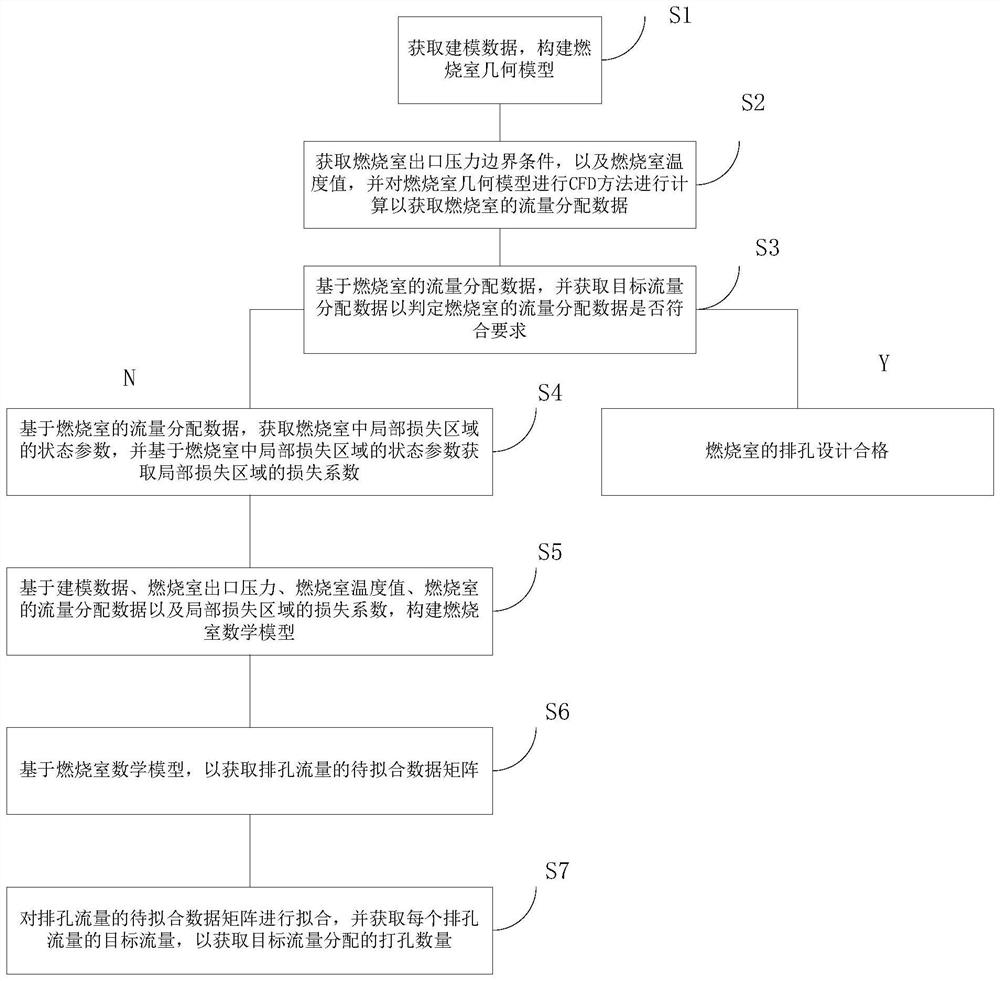

[0058] Embodiment 1 of the present invention provides a flow distribution design method for a miniature evaporator tube combustor, including:

[0059] S1: Obtain modeling data and build a geometric model of the combustion chamber;

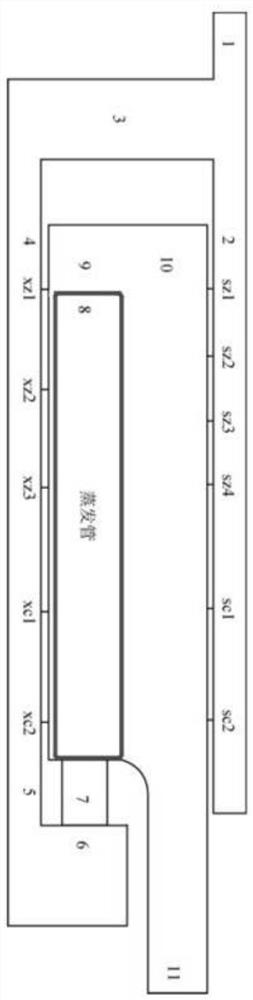

[0060] Further, the modeling data includes the width of the combustion chamber inlet, the height of the ring, the width of the head, the length of the upper and lower rings, the inner and outer diameters of the evaporation tube, the length of the evaporation tube, the size of the flame tube and the height of the outlet of the combustion chamber;

[0061] S2: Obtain the outlet pressure boundary conditions of the combustor and the temperature value of the combustor, and perform CFD calculation on the geometric model of the combustor to obtain the flow distribution data of the combustor, which includes the flow distribution data of each row Orifice flow and evaporation tube flow;

[0062] S3: Obtain target flow distribution data based on the flow dis...

Embodiment 2

[0138] Embodiment 2 of the present invention provides a flow distribution design device for a miniature evaporator tube combustor, including:

[0139] Data acquisition module: used to acquire modeling data and build a combustion chamber geometric model;

[0140] Calculation module: used to obtain the combustion chamber outlet pressure boundary condition and the combustion chamber temperature value, and perform CFD calculation on the combustion chamber geometric model to obtain the flow distribution data of the combustion chamber, the flow distribution data of the combustion chamber includes The flow rate of each row hole and the flow rate of the evaporation tube;

[0141] Judgment module: used to obtain target flow distribution data based on the flow distribution data of the combustion chamber to determine whether the flow distribution data of the combustion chamber meets the requirements;

[0142] If not, then execute the step of S4;

[0143] If so, the design of the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com