Sediment sampler

A sampler and sediment technology, applied in sampling, instruments, scientific instruments, etc., can solve the problems of cross-sectional structure interference and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

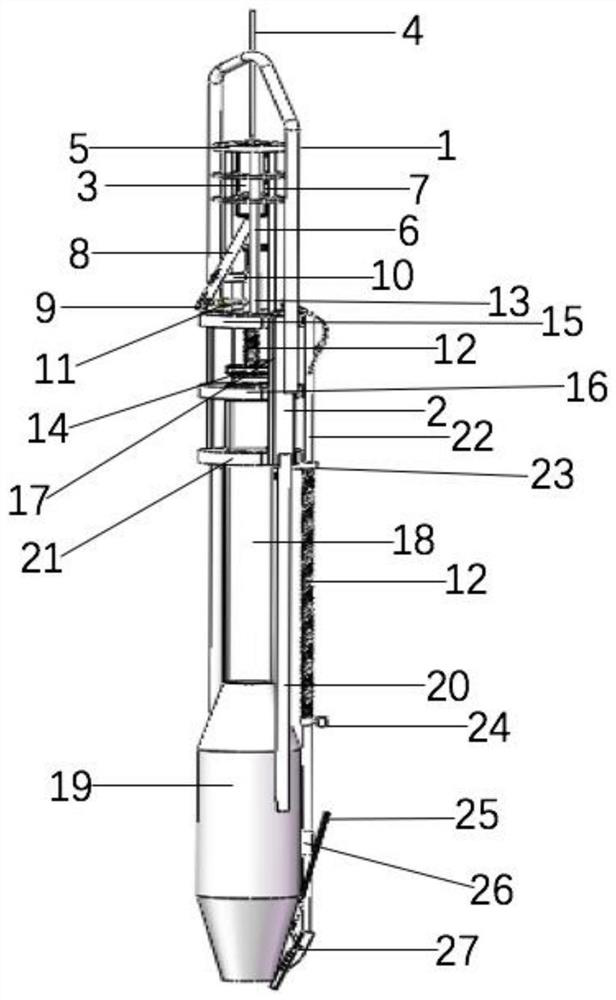

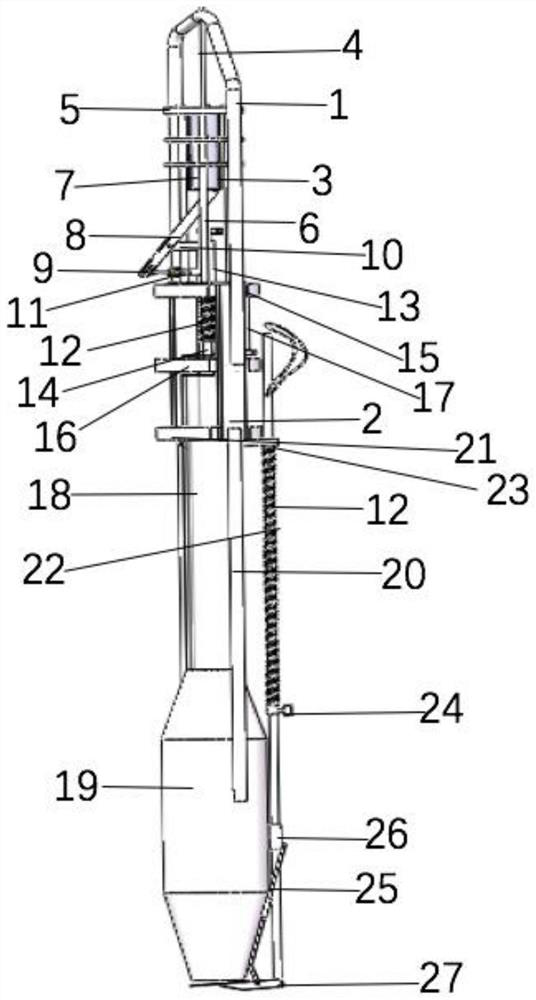

[0031] In this example, see Figure 1-Figure 2 , a sediment sampler, including a handle 1, a connecting plate 2, a cam weight 3, a sampling rope 4, a locking mechanism, a piston 14, a sampling tube 18, a collection cavity 19, a connecting rod 20 and a sealing shovel 27; The cam weight 3 is hung on the lower end of the sampling rope 4, so that the cam weight 3 is on the top of the sediment sampler; the handle 1 is connected to the collection cavity 19 through the connecting plate 2 and the connecting rod 20, so that the The handle 1 is fixedly connected to the lower part of the sediment sampler; the collection chamber 19 is installed in the middle and lower part of the sampling pipe 18; a locking mechanism is installed between the cam weight 3 and the sampling pipe 18, and the locking mechanism is connected to the collection chamber 19 the sealing shovel 27 of the lower port; before using the sediment sampler, the sampling rope 4 is hung with the cam weight 3 without touching t...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, especially in that:

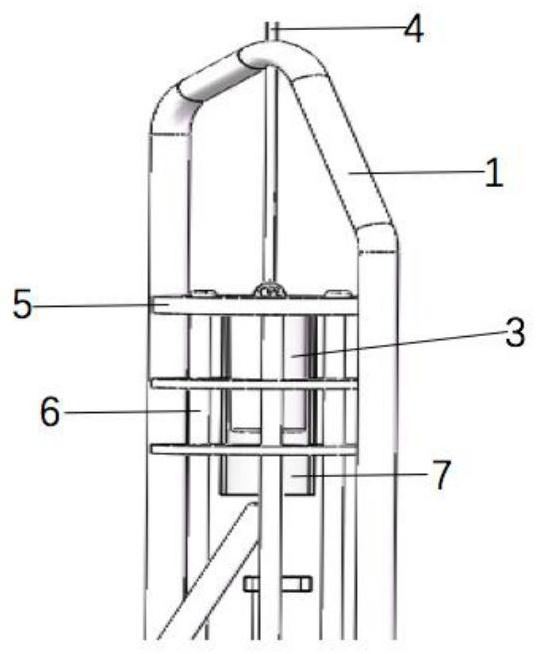

[0034] In this example, see Figure 1-Figure 12 , the handle 1 is welded on the connecting plates 2 on both sides, and the connecting plates on both sides are in a parallel state; the center of the handle is provided with a cylindrical rope hole; the cam weight 3 is a cylinder, and the upper end of the weight is provided with a rope ring, A sampling rope 4 is sheathed on the rope ring; the length of the sampling rope 4 is determined according to the depth of the water and the depth of the sediment, and its upper end passes through the rope hole of the handle; They are: upper cam cover, middle cam cover, and lower cam cover; the three cam covers are concentric and parallel, and have the same outer diameter; the inner diameter and thickness of the middle cam cover and the lower cam cover are equal, and the middle cam cover The inner diameter of the cover is larger than the inner diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com