Novel flange

A flange, a new type of technology, applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of reducing engineering efficiency, slowing down construction progress, wasting manpower and material resources, etc., to improve engineering efficiency and speed up The effect of construction progress and installation is quick and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

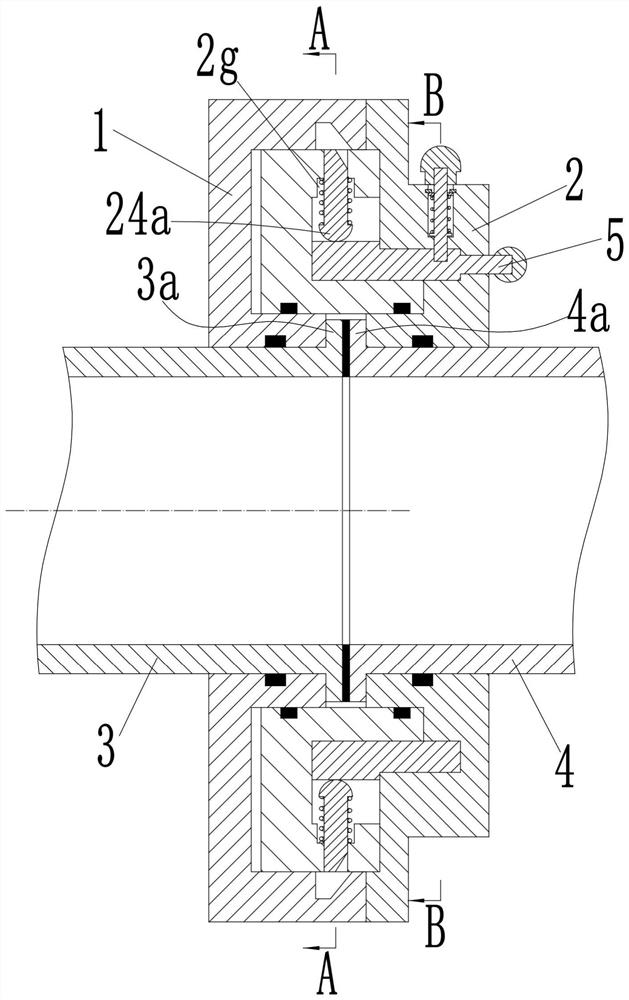

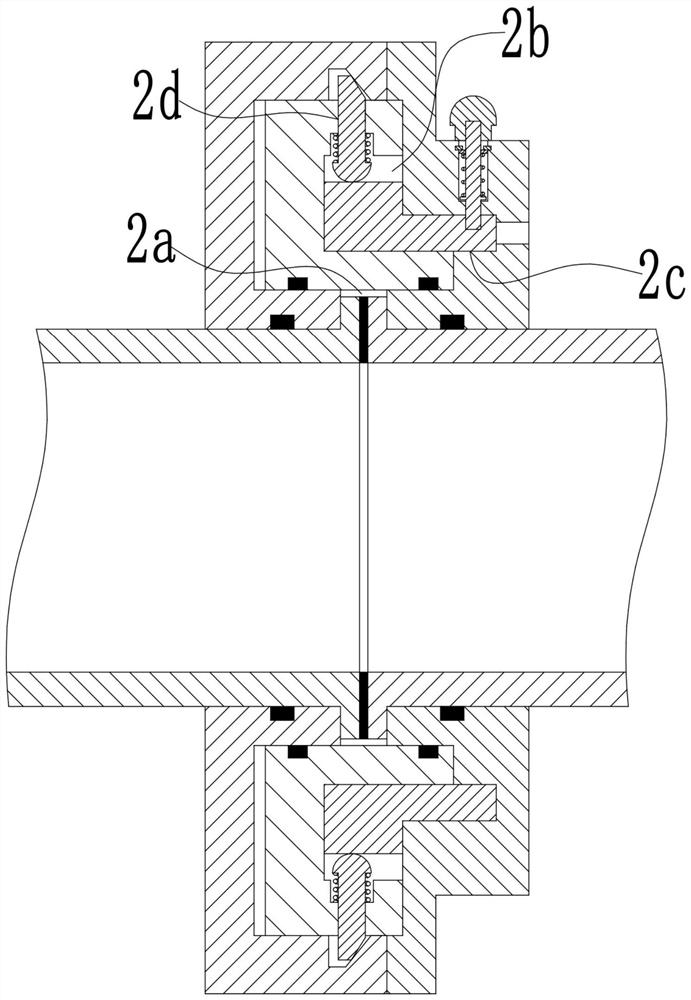

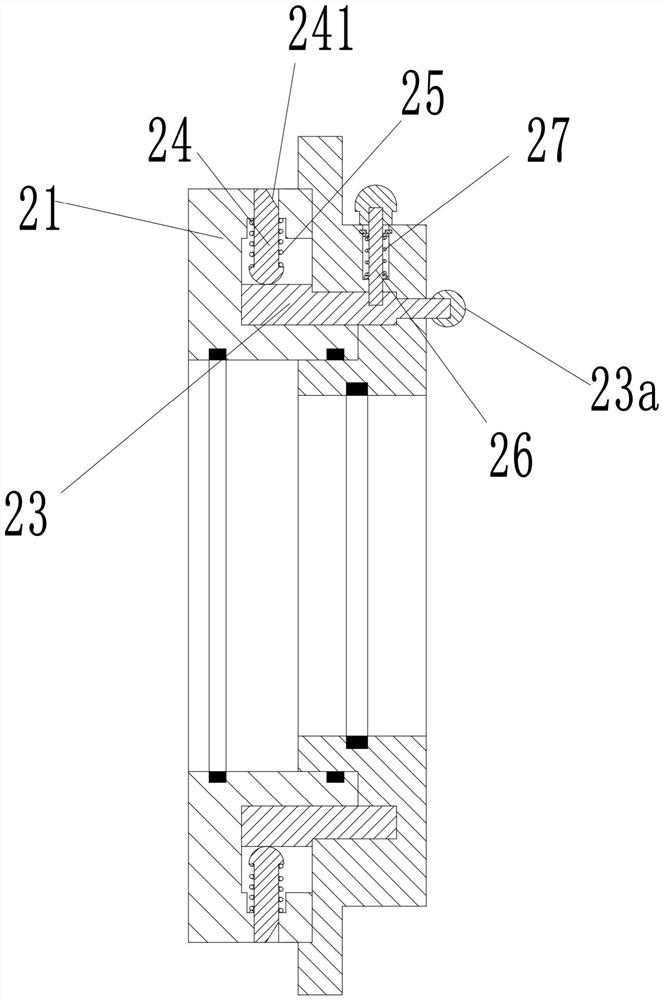

[0024] see Figure 1-10 As shown, a new type of flange is arranged between the left pipe 3 and the right pipe 4, including a left flange 1 and a right flange 2, the right end of the left flange 1 is provided with an annular slot 11, and the right The left end of the flange 2 is fixedly installed with an annular protrusion 21 for inserting into the annular slot 11, and the inner hole of the annular protrusion 21 forms a mounting groove 2a between the left flange 1 and the right flange 2, and the left The right end of pipeline 3 is radially provided with a left flange 3a extending into the installation groove 2a, and the left end of the right pipeline 4 is radially provided with a right flange 4a extending into the installation groove 2a; the annular slot 11 is provided with an annular locking groove 12 on the inner side wall; the right end surface of the annular protrusion 21 is provided with a first annular groove 2b, and the left end surface of the right flange 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com