A water gushing sealing device and its control method

A technology of a plugging device and a control method, which is applied in the directions of earthwork drilling, bolt installation, sealing/isolation, etc., which can solve problems such as inability to efficiently and conveniently block water gushing, and achieve avoidance of adverse effects, reliable plugging, and full reliability The effect of gushing water blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

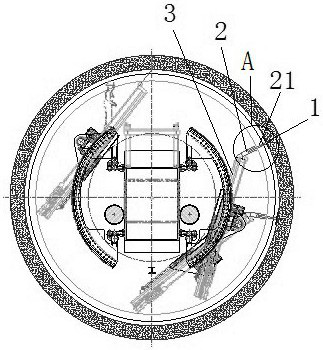

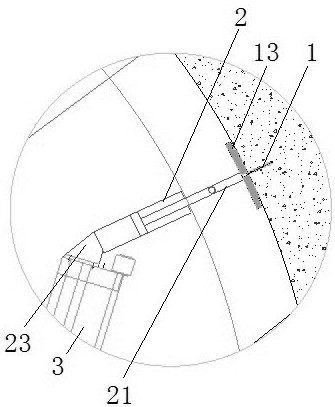

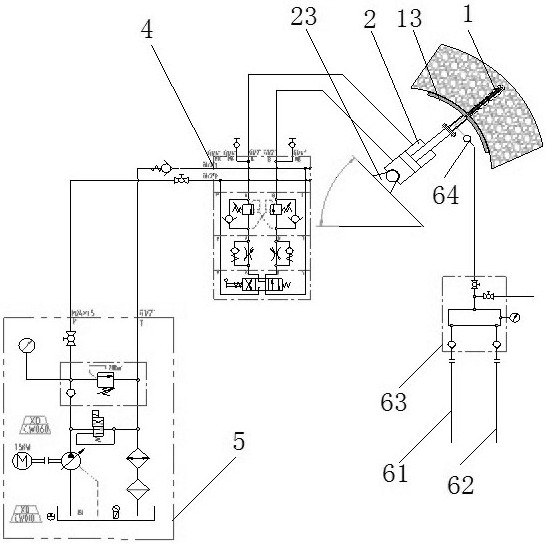

[0028] Embodiment 1, a kind of gushing water blocking device, such as image 3 , 4 As shown, it includes a water stop rod 1 made of seamless steel pipe, and uses the water stop rod 1 to block the water gushing hole. Such as figure 1 , 2 As shown, the water stop rod 1 is connected with an oil cylinder 2, and the oil cylinder 2 is connected with the rotating part of the rock bolter 3, and the oil cylinder 2 is connected with the hydraulic pump station 5 through the control valve group 4. The rotation of the bolter 3 can drive the oil cylinder 2 to rotate in the tunnel, and can drive the oil cylinder 2 to any position that needs to be blocked for construction. The extension of the oil cylinder 2 can drive the water stop rod 1 to insert into the water gushing hole to realize the water gushing hole automatic blocking.

[0029] Further, the oil cylinder 2 is hinged on the rotating part of the rock bolt 3 through the hinge seat 23, the hinge seat 23 is a universal ball joint seat...

Embodiment 2

[0034] Embodiment 2, a control method of a water gushing sealing device, comprising the following steps:

[0035] ① Control the rotation of the bolter 3 until the water stop rod 1 reaches the water gushing hole;

[0036] ② Control the extension of the oil cylinder 2 until the oil cylinder 2 drives the water stop rod 1 to insert into the water gushing hole to ensure that the arc-shaped sealing plate 13 fits with the wall surface at the front end of the water gushing hole;

[0037] ③ If the water gushing is effectively controlled, use expansion bolts to fix the arc-shaped sealing plate 13 on the wall;

[0038] ④ If the water gushing is not under control, control the high-pressure grouting system to perform double-liquid grouting into the water stop rod 1, and use expansion bolts to fix the arc-shaped sealing plate 13 on the wall;

[0039] ⑤Remove the connection between the water stop rod 1 and the oil cylinder 2, and remove the oil cylinder 2 from the rock bolter 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com