Intelligent blowing-carding production line and production method thereof

A production line, blowing and carding technology, applied in the textile field, can solve the problems of long working hours, unstable structure, noise pollution, etc., to minimize noise, avoid maintenance costs, and save space in workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The following experimental examples and examples are used to further illustrate but not limit the present invention.

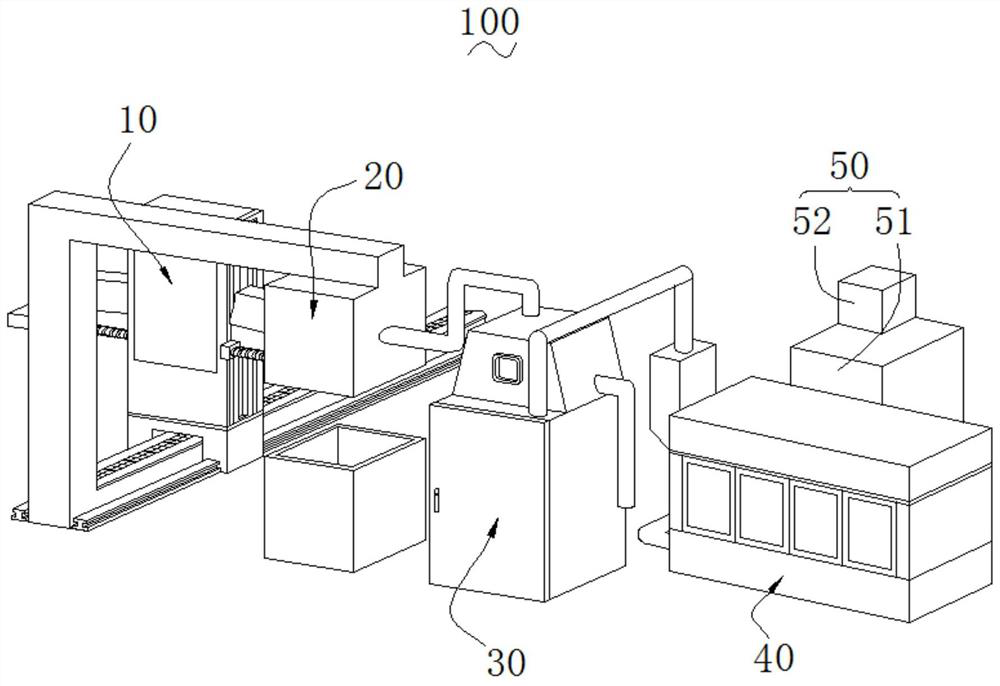

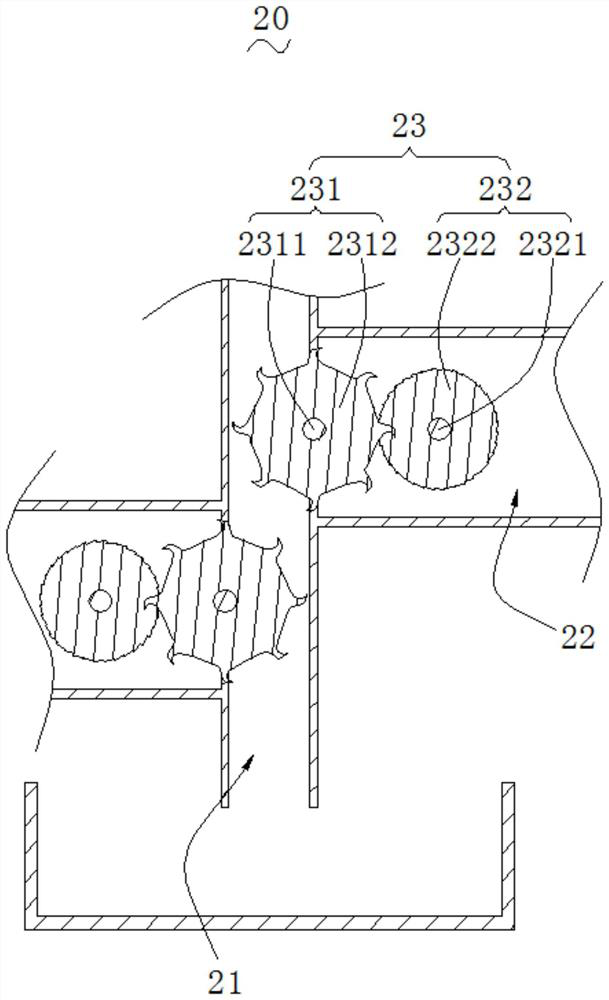

[0038] Please refer to Figure 1 to Figure 6 , the present invention provides a kind of blowing-carding intelligent production line 100, described blowing-carding intelligent production line 100 comprises cotton grasping device 10, heavy object separation device 20, fine opening device 30, multi-bin cotton mixing device 40 and carding device 50.

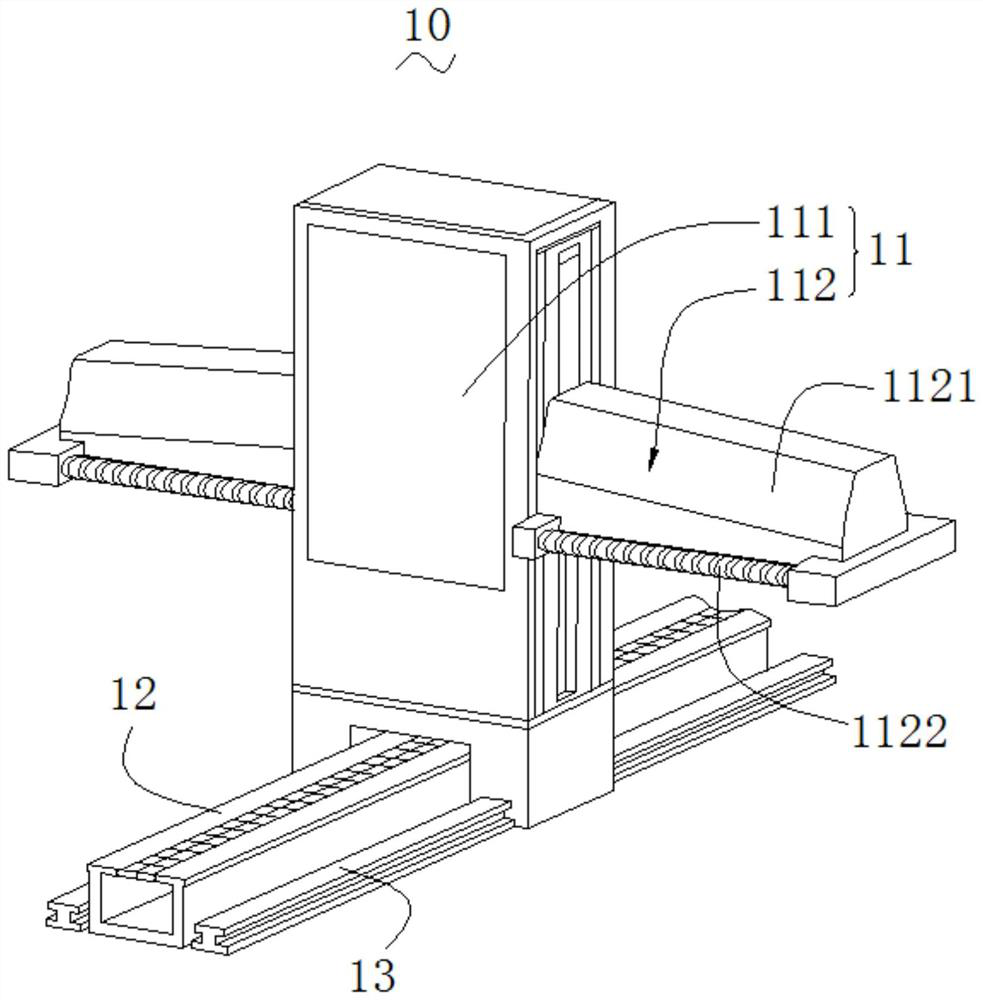

[0039] The cotton grabbing device 10 is used to grab the raw cotton of the cotton pile. Specifically, the grabbing device 10 includes a cotton suction machine main body 11 , a cotton suction channel 12 arranged at the bottom of the cotton suction machine main body 11 , and sliding rails 13 provided at both sides of the cotton suction channel 12 . Wherein, the main body 11 of the cotton suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com