Uniform flow plating device for inner wall of pipe fitting

A technology of uniform flow and pipe fittings, applied in the direction of current conduction devices, current insulation devices, sealing devices, etc., can solve problems such as uneven coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

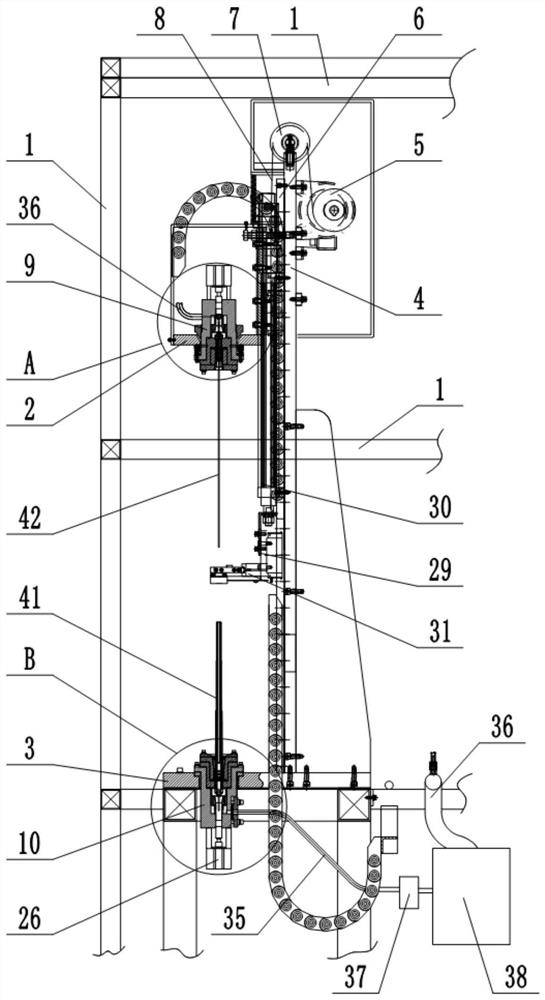

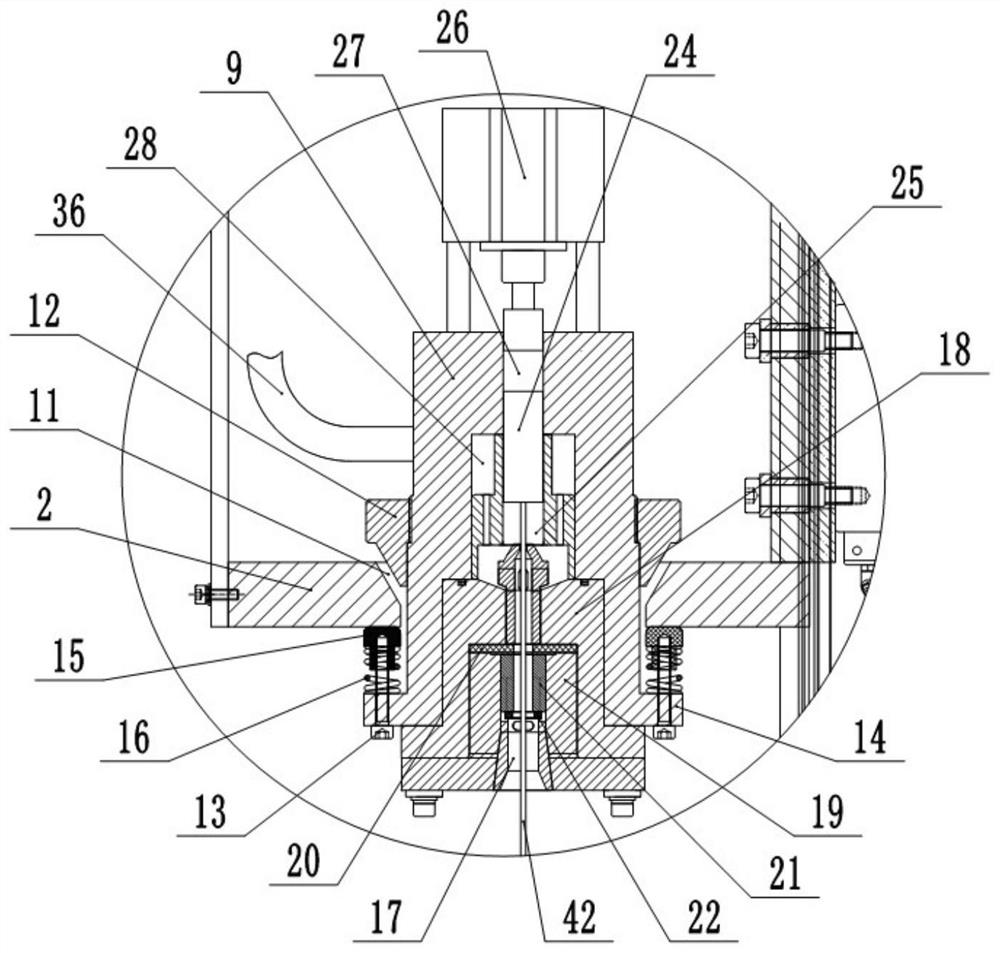

[0037] This embodiment is basically as figure 1 Shown: a uniform flow plating device for the inner wall of the pipe fitting, including a frame 1, a fixing mechanism, a pipe fitting clamping mechanism and an electroplating solution circulation mechanism for filling the electroplating solution into the pipe fitting 41. The fixing mechanism includes an upper mold 2 and a lower mold 3 directly opposite to the upper mold 2, and the lower mold 3 is fixedly installed on the frame 1 by screws. The upper mold 2 is connected with a drive mechanism 1 for driving the upper mold 2 to move. In this embodiment, the drive mechanism 1 includes a guide plate 4 and a drive motor 5 fixedly connected to the guide plate 4. The upper mold 2 is vertically slidably connected to the guide plate. On the plate 4, specifically, the guide plate 4 is welded with a vertically arranged guide rail 6, and the right end of the upper mold 2 is fixedly mounted on the slide block of the guide rail 6 by screws. The...

Embodiment 2

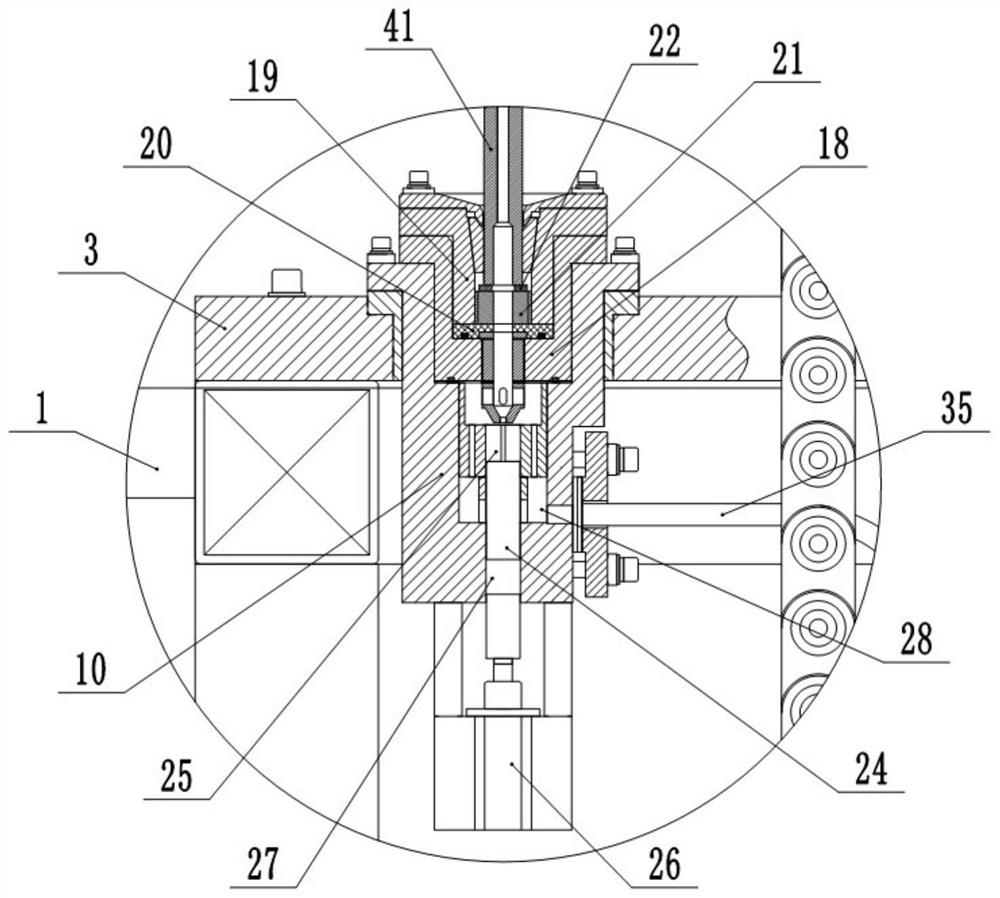

[0057] The difference between this embodiment and Embodiment 1 is that: Figure 5 As shown, the bottom of the lower mold 3 is fixed with a leaking liquid contact box 39 by screws, and the bottom wall of the leakage liquid contact box 39 is provided with a round hole for the output end of the telescopic cylinder 26 to pass through. The bottom wall of 39 is bonded with seal ring three 40, and the output end of telescopic cylinder 26 passes seal ring three 40.

[0058] In this embodiment, the telescopic cylinder 26 on the lower fixed block 10 drives the conductive rod 24 to move downward or upward. Therefore, during the movement of the conductive rod 24, the seal 27 also moves relative to the guide hole. At this time, the electroplating solution may flow from the guide hole. The hole oozes out and drips in the leaking liquid contact box 39 to prevent the electroplating solution from directly dripping on the telescopic cylinder 26 and the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com