Label checking machine

A label inspection machine and label inspection technology, applied in the field of label inspection machines, can solve the problems of labels not being attached, missing labels, and different viscosity, and achieve the effects of avoiding uneven application, simple structure, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

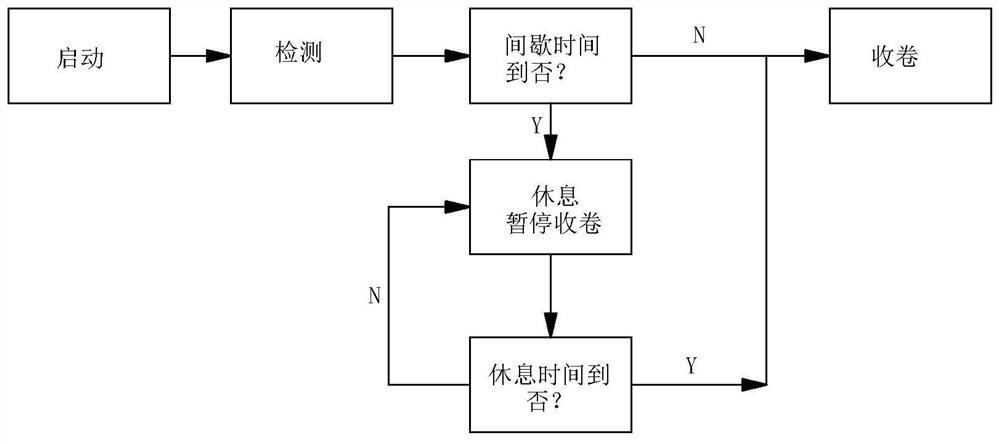

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

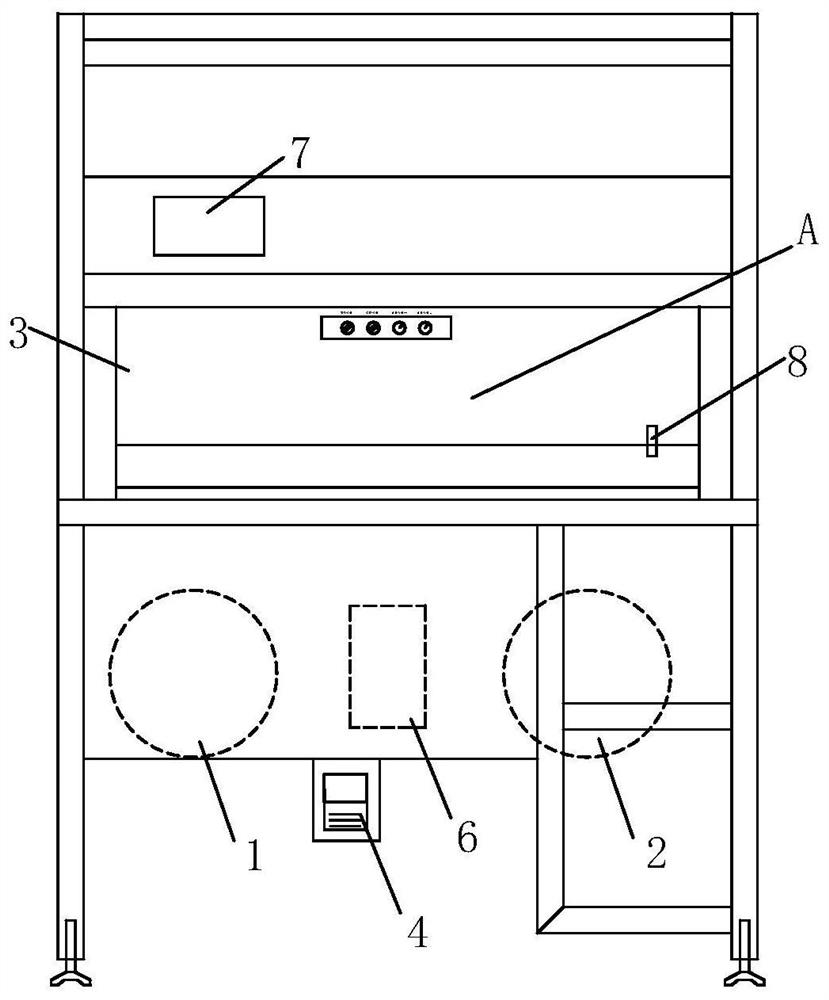

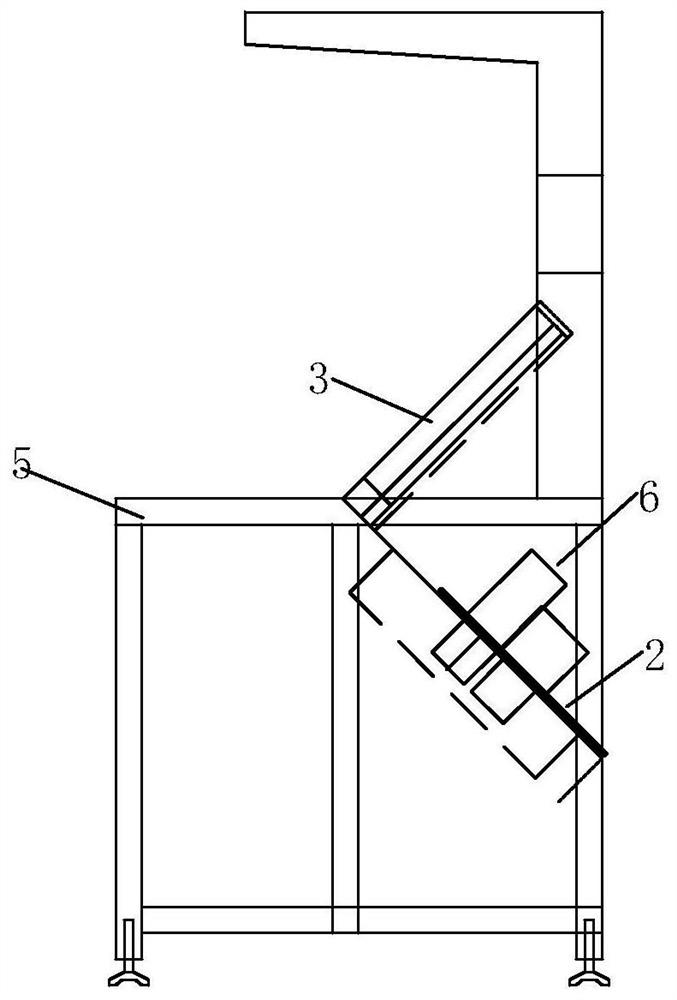

[0033] The invention provides a label checking machine, figure 1 The front view of the overall structure schematic diagram of the present invention. figure 2 The left view of the overall structure schematic diagram of the present invention. like Figure 1-2 As shown: the marking inspection machine provided by the present invention includes: rewinding reel 1, rewinding reel 2, length counting shaft 3, foot switch 4, machine main frame 5, servo motor 6, touch screen 7 and counting sensor 8.

[0034] Rewinding reel 1, rewinding reel 2, meter length rotating shaft 3, foot switch 4, servo motor 6, touch screen 7 and counting sensor 8 are all installed on the main frame 5 of the machine.

[0035] The rewinding reel 1 is used as an unwinding reel during the label inspection process. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com