Material control device for bagging during rice processing

A rice processing and hopper technology, applied in the field of food processing, can solve the problems of low efficiency and manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

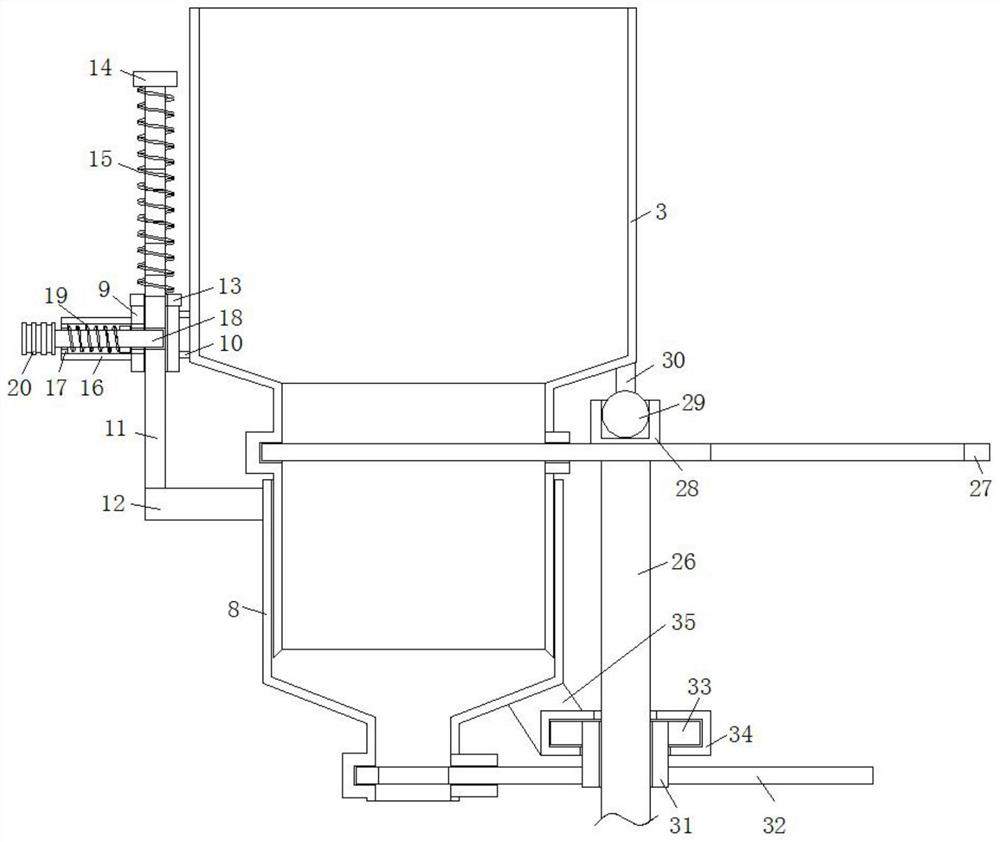

[0024] refer to Figure 1-3 , a material control device for bagging during rice processing, comprising a workbench 1, the four corners of the bottom of the workbench 1 are fixedly connected with support columns 2, a raw material bin 3 is arranged vertically above the workbench 1, and the raw material bin 3 A support frame 4 is fixedly connected between the bottom and the workbench 1. The table top of the workbench 1 is provided with a vertical through hole and is fixedly connected with an installation cylinder 6. The installation cylinder 6 is fixedly connected with a terminal feed pipe 5, and the terminal feed pipe The top of 5 is connected with a receiving hopper 7, the bottom of the raw material bin 3 is a closed structure and the outer sliding sleeve is provided with a control hopper 8, and one side of the raw material bin 3 is provided with a track tube 9, which is fixed between the track tube 9 and the raw material bin 3 A support arm 10 is connected, the inner side of t...

Embodiment 2

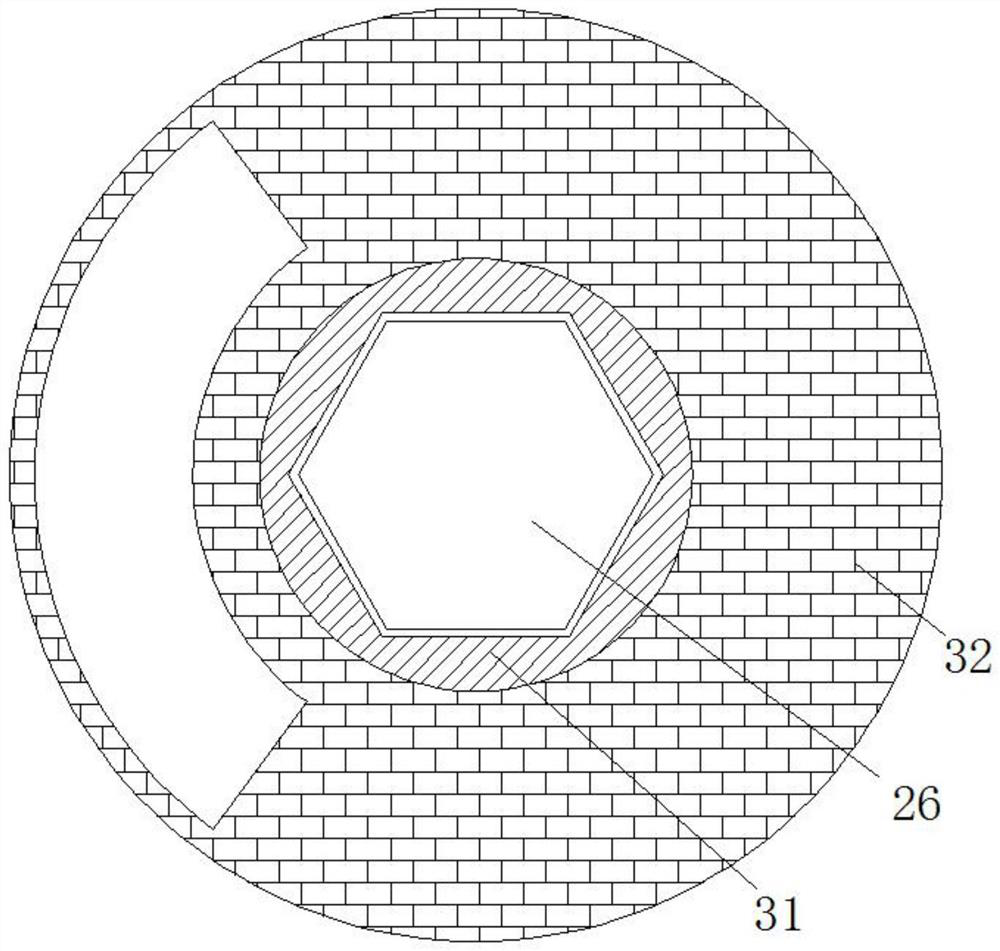

[0028] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, an outer ring 33 is fixedly connected to the outer side of the top of the polygonal sliding sleeve 31, and the outer rotating sleeve of the outer ring 33 is provided with a rotating cover 34, and the rotating cover 34 is connected to the control hopper. Two connecting columns 35 are fixedly connected between the outer walls of 8 .

[0029] In this embodiment, the polygonal sliding sleeve 31 is supported, and the lower material blocking plate 32 is more stable when rotating.

Embodiment 3

[0031] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a notch three is opened on the vertical side of the rotating seat 21, and the driving gear 25 passes through the notch three.

[0032] In this embodiment, the driving gear 25 connected to the output shaft of the motor 24 drives the operation of the whole mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com