Clutch-free synchronous gear shifting control method and system of hybrid power system

A hybrid power system, clutch synchronization technology, applied in hybrid vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of increased switching time, long power interruption time, high cost, etc., to reduce costs and reduce power interruption time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Such as the above shift control method, wherein,

[0088] Shift force F=200N, make the engine close to zero torque mode,

[0089] The half-cone angle of the synchronous ring cone surface is 7°, the locking angle is 51°,

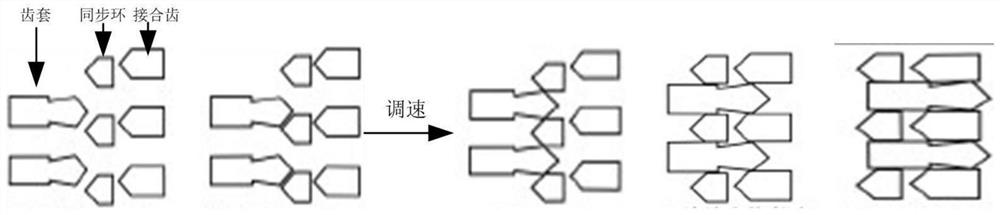

[0090] like Figure 5 As shown, the rotating speed of the engaging gear w=1000rpm, the rotating speed of the gear sleeve is 960rpm, the speed regulating motor regulates the engine speed, so that the rotating speed w of the engaging gear decreases with a certain slope. The speed crossing occurs at 150 ms, and the displacement of the gear sleeve changes greatly after the speed crossing point of the engaging tooth and the gear sleeve. It shows that the speed control system actively controls the rotation speed of the engaging teeth to make it cross with the rotating speed of the gear sleeve. At this time, the synchronous ring will open the shift opportunity window, and the gear sleeve can pass through the synchronous ring to complete the meshing with the...

Embodiment 2

[0092] The magnitude of the shifting force F is: F=150N, making the engine close to the zero torque mode,

[0093] The half cone angle of the synchronous ring cone is 6°30’, the locking angle is 52°,

[0094] like Figure 6 As shown, the rotational speed of the engaging gear w=2000rpm, and the rotating speed of the gear sleeve is 1960rpm. The speed regulating motor regulates the engine speed so that the rotational speed w of the engaging gear decreases with a certain slope. The speed crossing occurs at 160ms, and the displacement of the gear sleeve changes greatly after the speed crossing point of the engaging tooth and the gear sleeve. By simulating the different angular relationships of the gear sleeves and engaging teeth when meshing, both gear shifts can be achieved. It shows that the speed control system actively controls the rotation speed of the engaging teeth to make it cross with the rotating speed of the gear sleeve. At this time, the synchronous ring will open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com