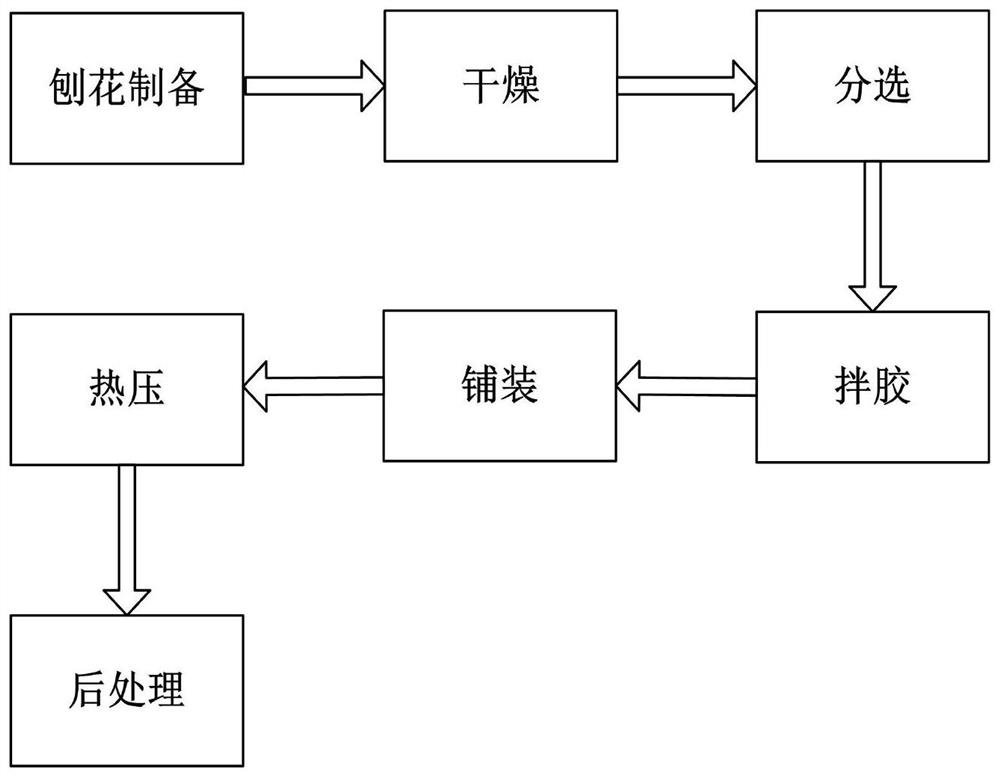

Shaving board production and processing technology

A processing technology and particleboard technology, which is applied in the direction of wood processing equipment, manufacturing tools, and pretreatment of molding materials, etc., can solve the problems of inability to collect glue, inability to mix glue with shavings, and poor preparation effect of particleboard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

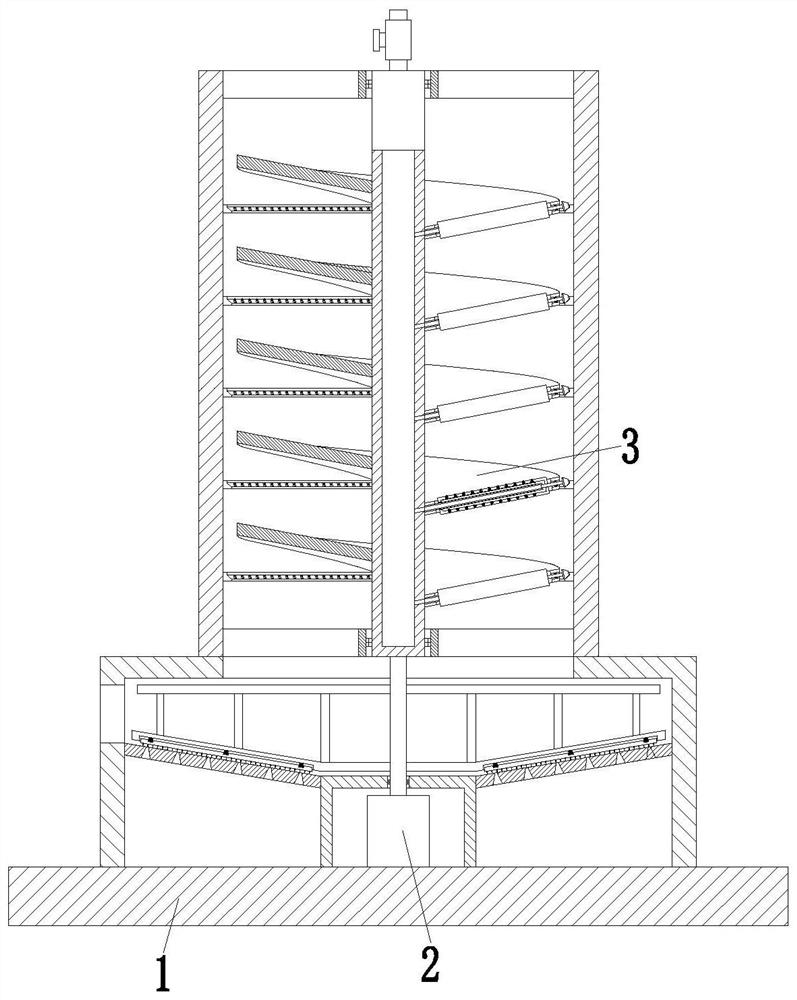

[0035] like Figure 1 to Figure 6 As shown, a particleboard production and processing technology, the particleboard production and processing technology adopts the following processing equipment, the processing equipment includes a base plate 1, a mixing device 2 and a glue mixing device 3, the base plate 1 is uniformly provided with mounting holes, the base plate 1 A mixing device 2 is installed on the upper end, and a glue mixing device 3 is installed on the upper end of the mixing device 2 .

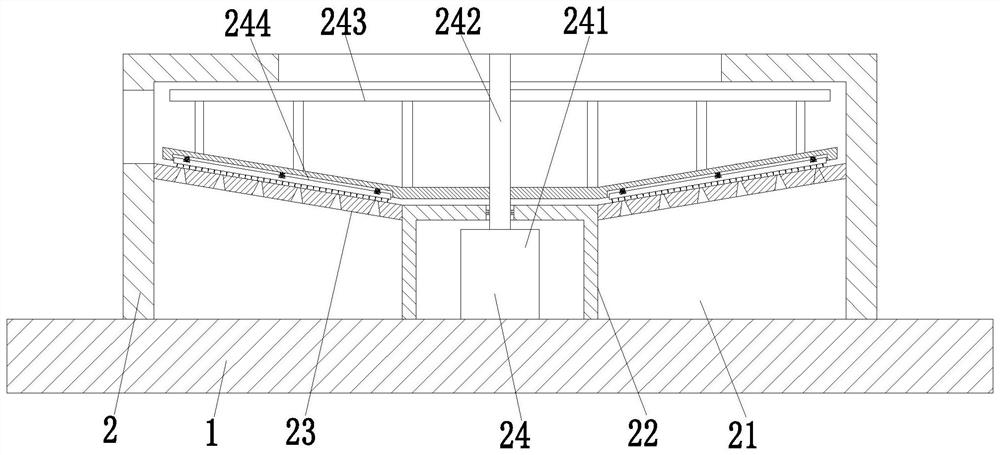

[0036] The mixing device 2 includes a fixed mount 21, a support frame 22, a mixing plate 23 and a mixing mechanism 24, the upper end of the bottom plate 1 is equipped with a fixed mount 21, the upper end of the fixed mount 21 is provided with an open groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com