Coconut cutting machine

A cutting machine, coconut technology, applied in metal processing and other directions, can solve the problems of dangerous manual operation, low degree of mechanization, poor economic benefits, etc., and achieve the effects of reducing personal injury and disability accidents, improving economic benefits, and expanding production scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

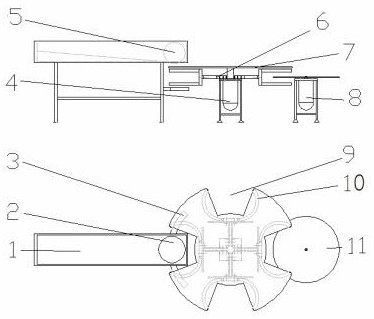

[0009] A rotary table 6 is provided, and a manipulator 10 is arranged on the rotary table 6. A baffle plate 7 is arranged above the manipulator 10. A feeding port 9 is provided at a position corresponding to the baffle plate 7 and the manipulator 10. The left side of the rotary table 6 There is a hopper 1 on the side, a feed port 2 is provided on the right side of the hopper 1, a slideway 3 is provided below the feed port 2, a cutting device is provided on the right side of the rotary table 6, and a saw blade is provided on the cutting device 11 and cutting motor 8.

[0010] Start the rotary motor 4 to drive the rotary table 6 and the baffle 7 to rotate together, and at the same time start the cutting motor 8 to drive the saw blade 11 to rotate at a high speed. At the mouth 2, the manipulator 10 is in the open state, and the coconut 5 in the hopper 1 falls to the lower slideway 3 through the feed port 2 and the discharge port 9. With the rotation of the rotary table, the manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com