Back face pressing and cutting device for sticky printing machine

An offset printing machine and backside technology, applied in the field of backside pressure-cutting devices, can solve the problems of insufficient cutting and inability to meet the needs of modern label production and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

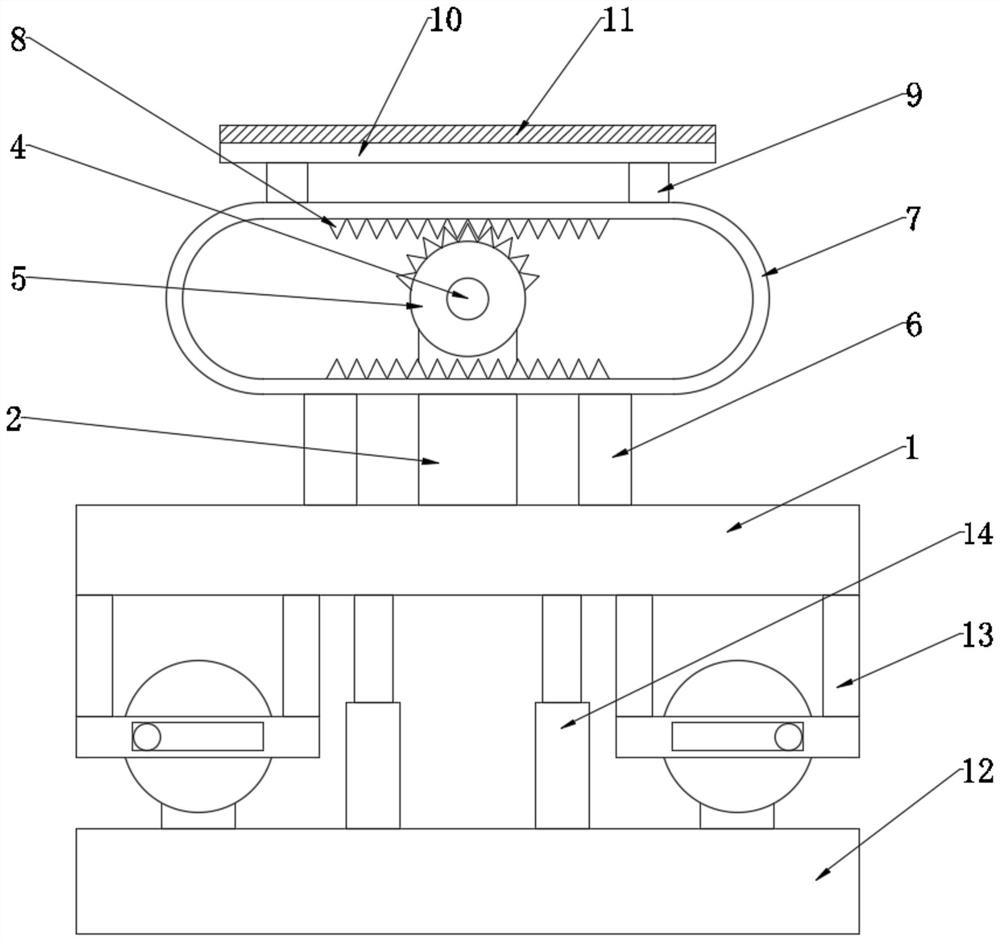

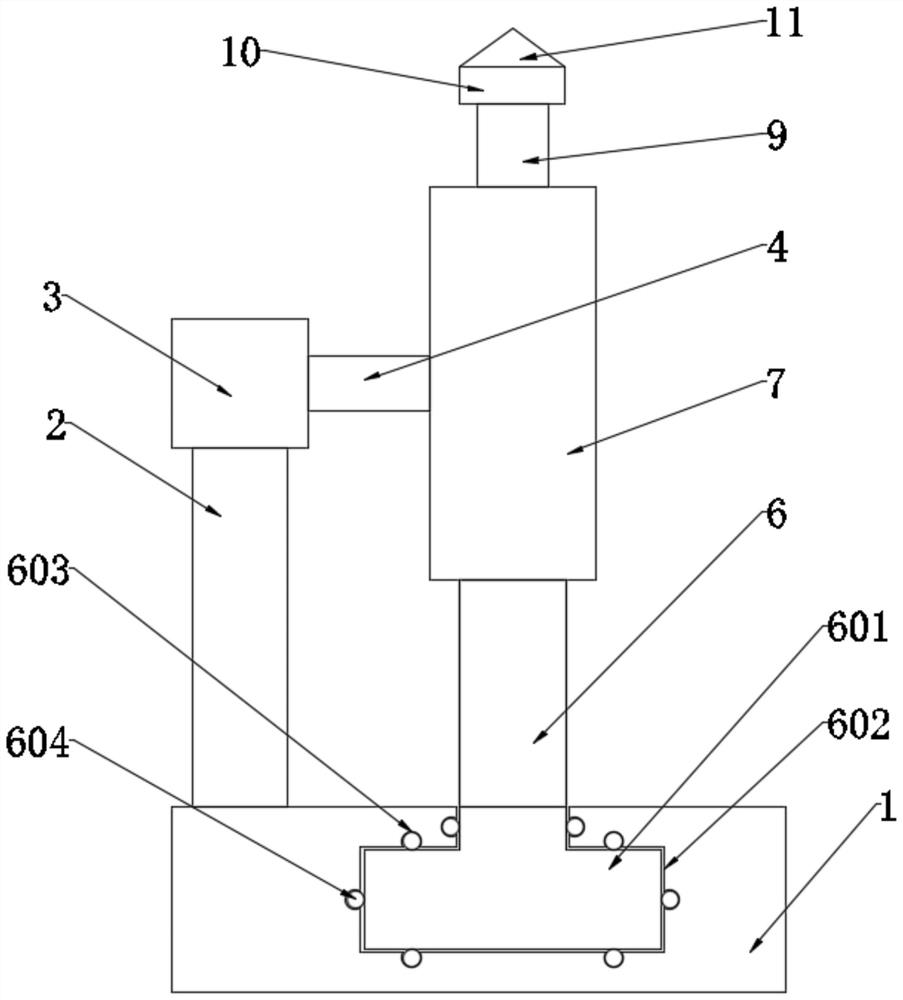

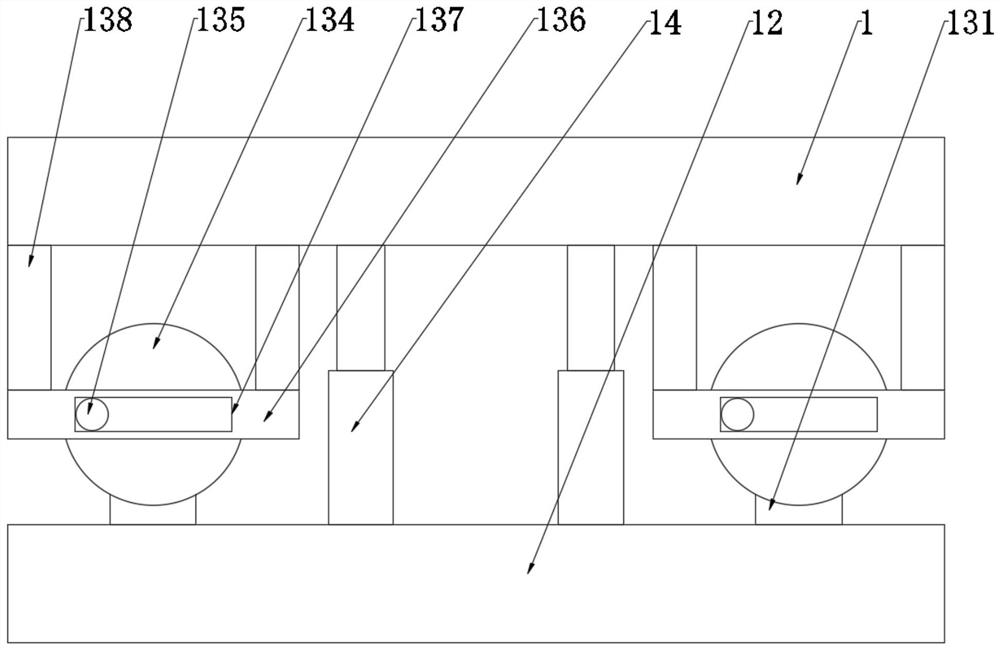

[0034] see Figure 1-6 , a back press-cutting device for self-adhesive printing machines, including a support base 1, a first support rod 2 is provided at the center of the upper surface of the support base 1, and a first drive motor is supported on the top end of the first support rod 2 3. The output end of the first drive motor 3 is connected to the first rotating shaft 4, the outer wall of the first rotating shaft 4 is fixed with an incomplete gear 5, the upper half of the circumferential wall of the incomplete gear 5 is provided with teeth, and the support seat 1 T-shaped clamping blocks 6 are provided on the left and right sides of the upper surface of the upper surface, and the T-shaped clamping block 6 is slidably connected with the support seat 1 through a clamping structure. The top of the T-shaped clamping block 6 is fixed with a waist ring 7, and the waist ring 7 A bar-shaped rack 8 is fixed on the inner walls of the upper and lower sides, and the incomplete gear 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com