Variable-stroke soft pneumatic gripping device and working method thereof

A technology of pneumatic clamping and driving device, applied in the field of mechanical processing, can solve the problems of items that cannot be large, short stroke of soft hand, insufficient grasping space, etc., and achieves large motion trajectory, high clamping adaptability, and clamping effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

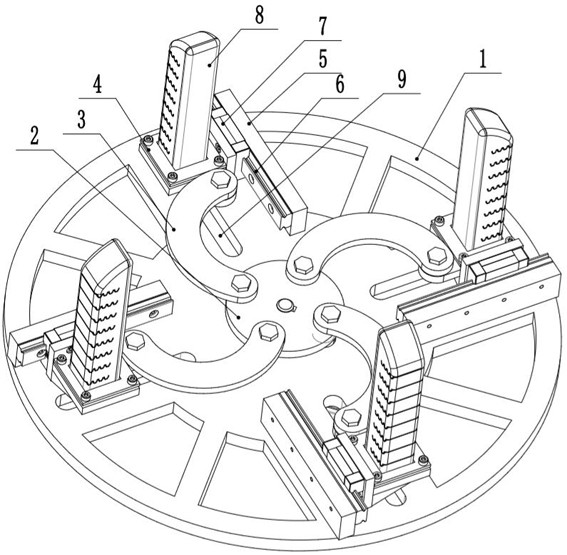

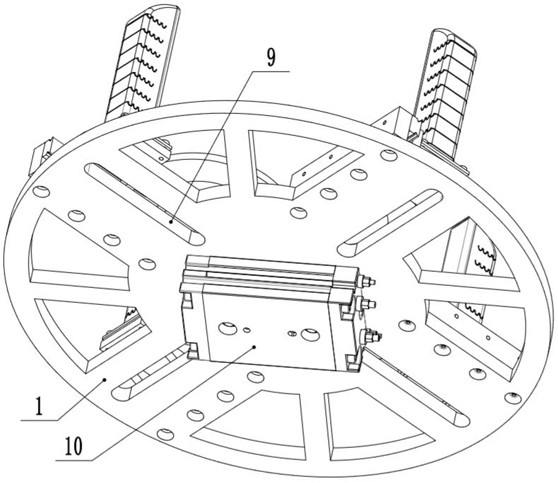

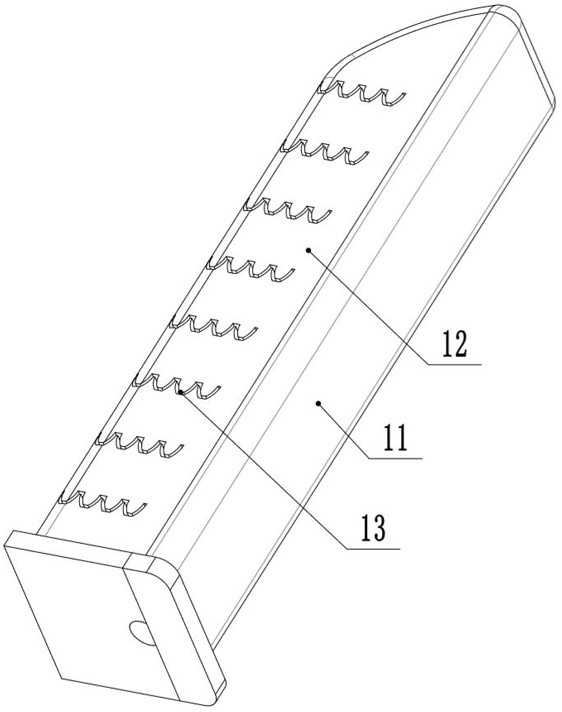

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0029] Such as Figure 1~6 As shown, a variable-stroke soft pneumatic clamping device includes an installation base plate 1, the center of the bottom end of the installation base plate is fixedly connected to the drive device 10, and the center of the top end of the installation base plate is rotated to connect the shaft flange 2, and the shaft flange is connected by the drive device. Drive, the top of the shaft flange rotates and connects some connecting rods 3 along its near edge, the end of the connecting rod away from the shaft flange is all rotated and connected to the moving seat 4, and the top of the moving seat is all fixedly connected to the air claw 8.

[0030] In the embodiment of the present invention, the top of the moving seat is provided with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com