Dumper compartment side plate welding platform and welding method

A welding platform and dump truck technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of reducing welding deformation, large deformation of side plate welds, and large deformation of welds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

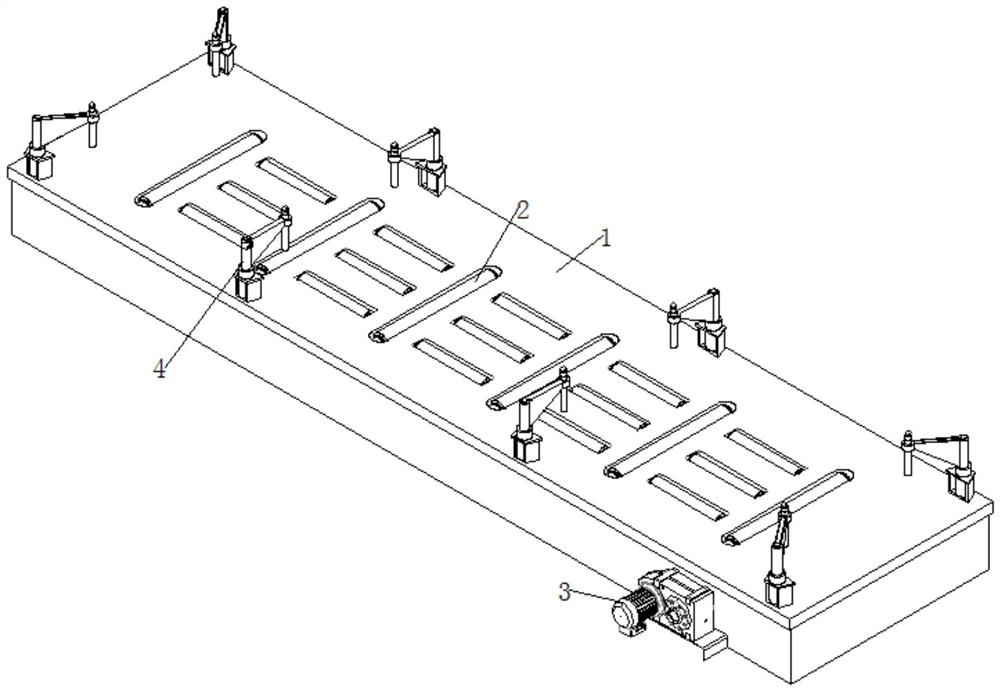

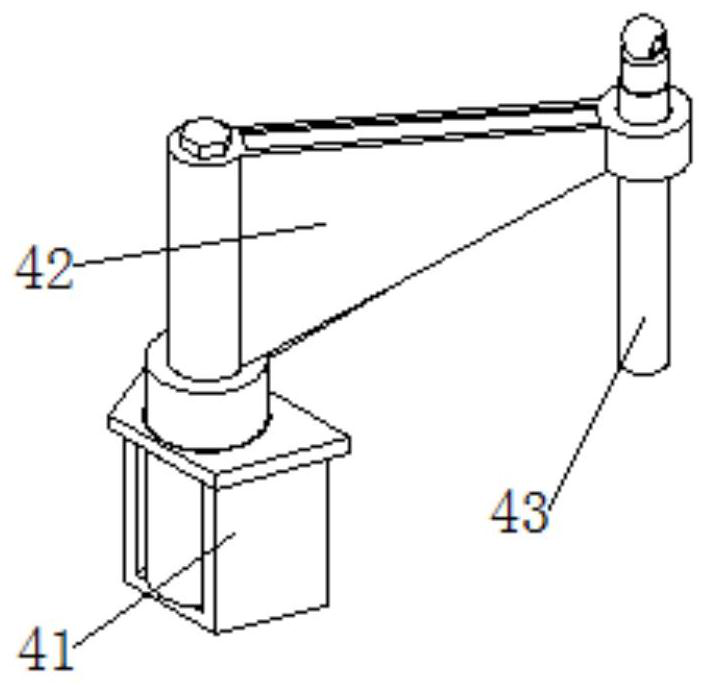

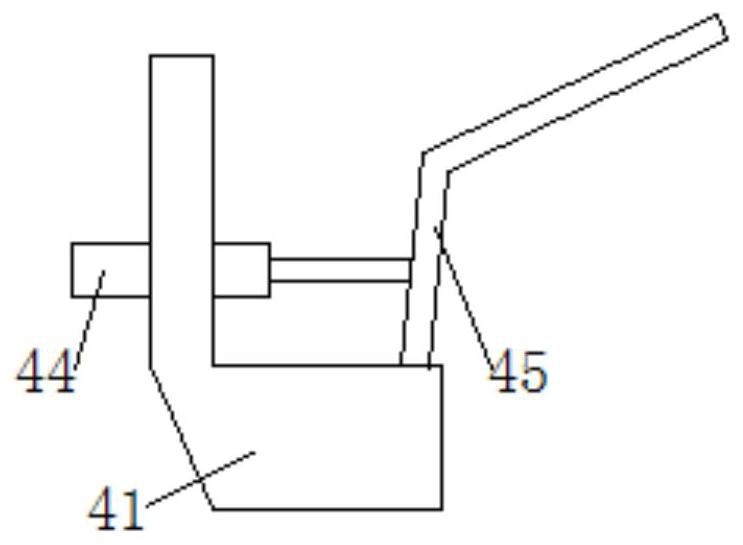

[0034] A kind of dump truck compartment side plate welding platform, such as figure 1 As shown, it includes a workbench 1, a lifting roller 2 and a drive mechanism 3 for controlling the lifting roller 2. The workbench 1 is provided with horizontally distributed and vertically distributed lifting rollers 2 alternately. The working boss 1 side is provided with pressing device 4. The length of the vertically distributed lifting rollers 2 is greater than the set length of the horizontally distributed lifting rollers 2 .

[0035] When in use, the stamped dump truck compartment side plate is placed on the workbench 1, and it is compressed and fixed by the pressing device 4; after fixing, the welding robot on the side of the workbench 1 welds the dump truck compartment side plate After the welding is finished, the pressing device 4 is separated from the side plate of the dump truck, and then the side plate of the dump truck is removed by the driving mechanism 3 and the lifting rolle...

Embodiment 2

[0039] On the basis of Embodiment 1, a welding method for a side plate welding platform of a dump truck compartment comprises the following steps:

[0040] Step 1, place the stamped side panel of the dump truck compartment on the workbench 1. The side panel of the dump truck compartment includes a bottom plate 5, a beam 6, a vertical beam 7, a column 8 and a fence 9, and pass through the pressing device 4 to fix.

[0041] Step two, such as Figure 4 and Figure 5 As shown, the beam 6 and the vertical beam 7 form a side plate grid 10, and the vertical weld 11 and the oblique weld 12 on the z-axis direction in the side plate grid 10 are welded in order from top to bottom; The plate grid 10 is a unit cell, and the unit cells on the bottom plate 5 are welded in the order from left to right, first down and then up.

[0042] Due to the short length of the vertical weld 11, the vertical weld 11 is generally not greater than 80mm and the dispersion is relatively uniform, so the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com