Casting sand box turnover machine

A box turning machine and sand box technology, which is applied in foundry equipment, manufacturing tools, and smoke removal, etc., can solve the problems of inability to separate molding sand and castings well, and large dust from pouring sand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

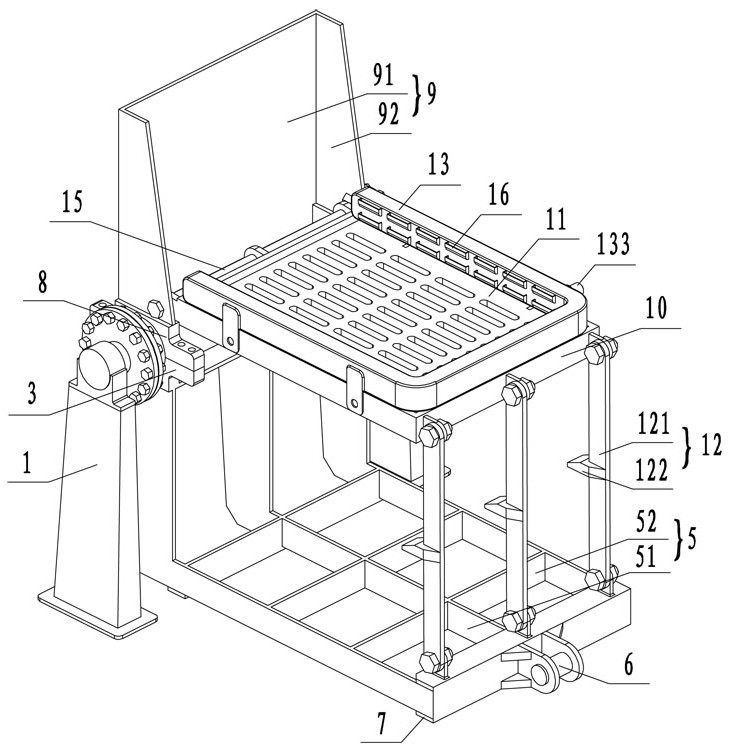

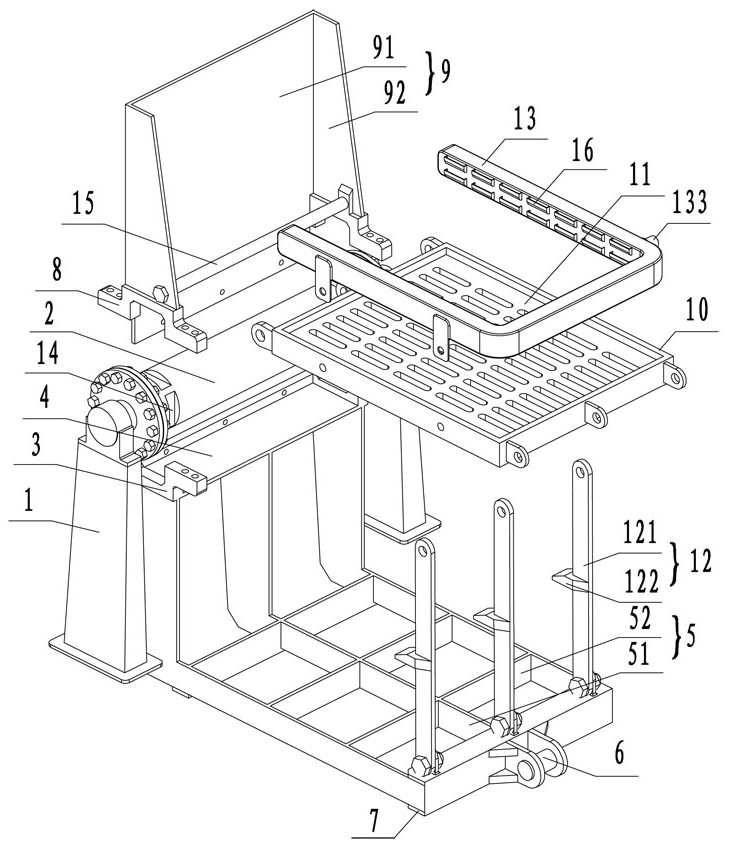

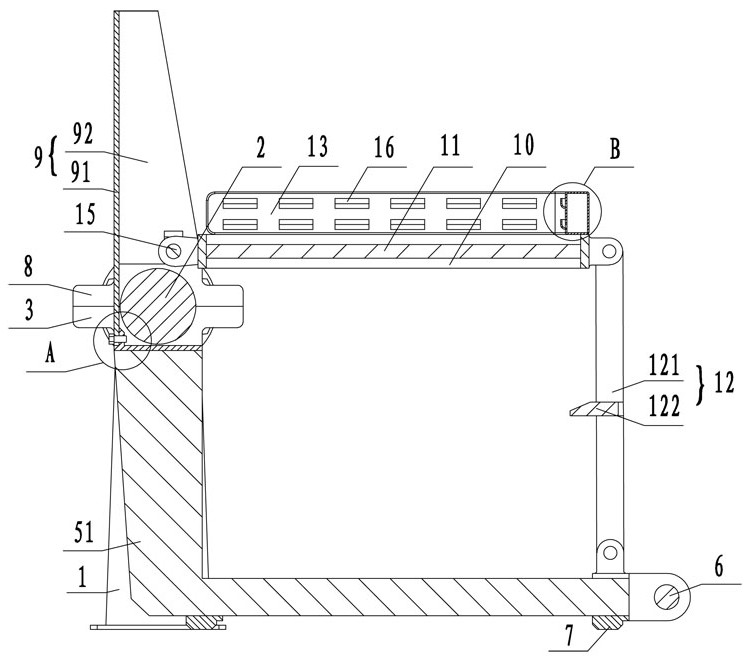

[0032] like Figure 1~Figure 6 As shown, a casting sand box turning machine includes a rotary unit, a bearing unit for carrying the sand box, a chute unit for sand falling, and a limiting unit for limiting the sand box. The rotary unit includes two sides The bracket 1 and the rotary shaft 2 that is rotatably arranged between the brackets 1 on both sides, the rotary shaft 2 is located at the top of the bracket 1, and the two ends of the rotary shaft 2 are symmetrically provided with slots 14.

[0033] Taking the radial direction of the rotary shaft 2 as the center of symmetry, the lower part of the rotary shaft 2 is provided with the bearing unit. The bearing unit includes the lower decks 3 on both sides, the connecting plates 4 fixedly connected to the decks on both sides, and the connecting plates fixedly arranged on the connecting plates. The "L" shaped bracket 5 below the plate 4, the bracket 5 is used to carry the sand box;

[0034] Specifically, the bracket 5 includes th...

Embodiment 2

[0050] like Figure 7 As shown, this embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that in this embodiment, no driving is set as the turning power, and the bracket 1 on one side is provided with a geared motor 17, so The deceleration motor 17 is connected to the rotary shaft 2 through transmission, and the deceleration motor 17 is used as the turning power to perform the operation of turning over the box and dumping sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com