Bean processing spiral dust-proof stone removing method

A dust-free stone removal, spiral technology, applied in the cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc., can solve the problems of a lot of dust, high vibration and noise, poor production continuity, etc. The degree of stone removal, the reduction of wear and tear, and the effect of smooth falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

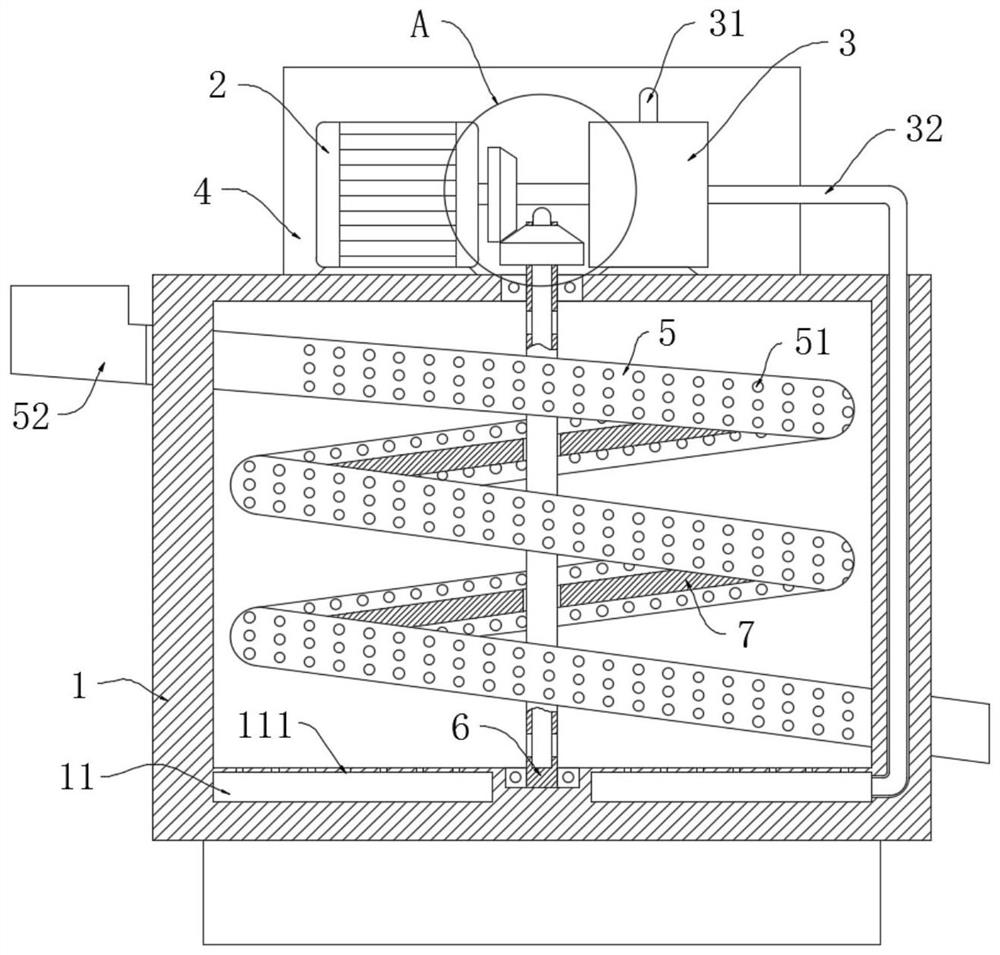

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

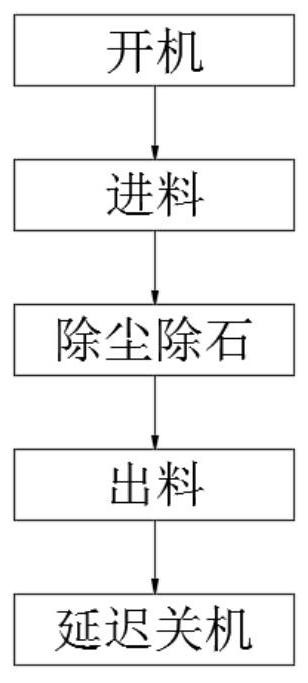

[0036] refer to Figure 1-7 A method for spiral dust-free stone removal for bean processing, comprising the following main steps:

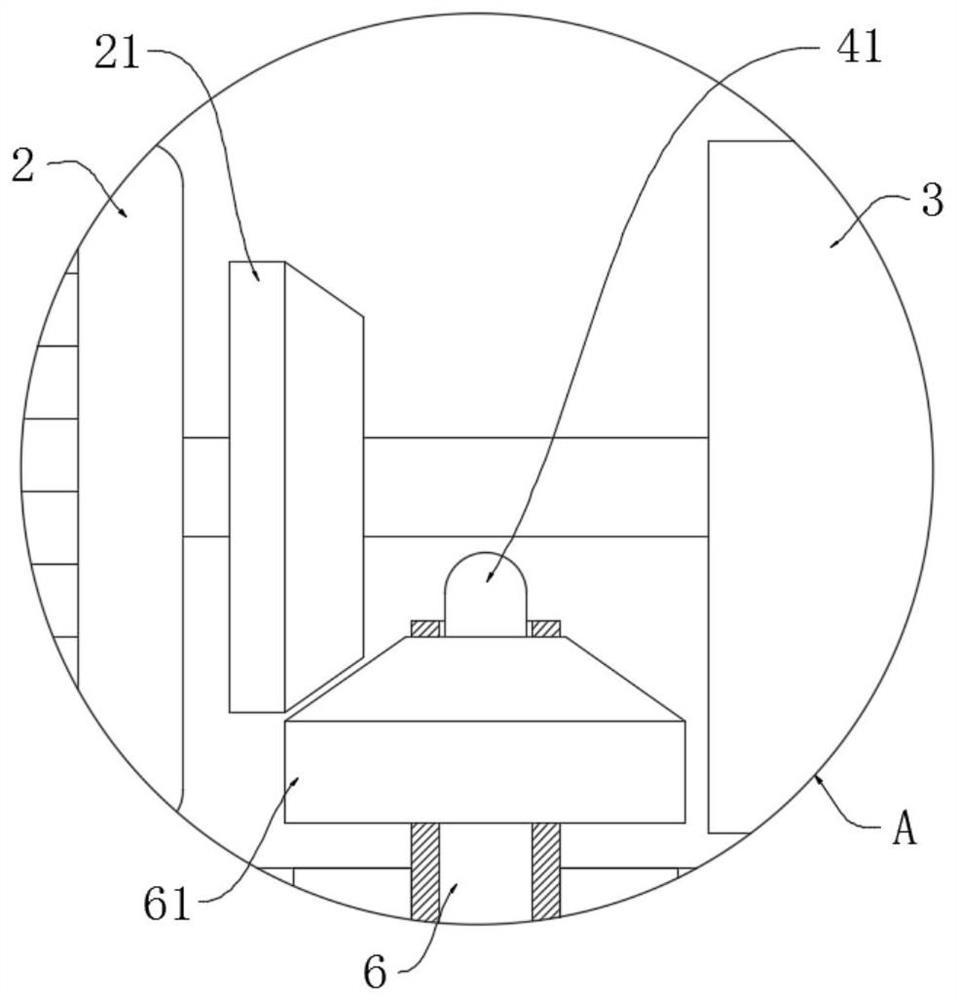

[0037] a: Turn on the power; turn on the power, start the motor 2 to make the fan box 3 work and make the driving bevel gear 21 rotate;

[0038] b: Feeding; the bean raw material is continuously poured through the feeding hopper 52 at a constant speed, and the bean raw material enters the spiral tube 5;

[0039] c: Dust removal and stone removal; the driving bevel gear 21 drives the hollow shaft 6 to rotate through the driven bevel gear 61, so that the thick spiral blade 7 rotates, and the thick spiral blade 7 continuously hits the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com