Dust suppression device

A technology of electrical boxes and fog cannons, applied in lifting devices, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve problems such as loud noise and vibration, and inconvenient dust suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

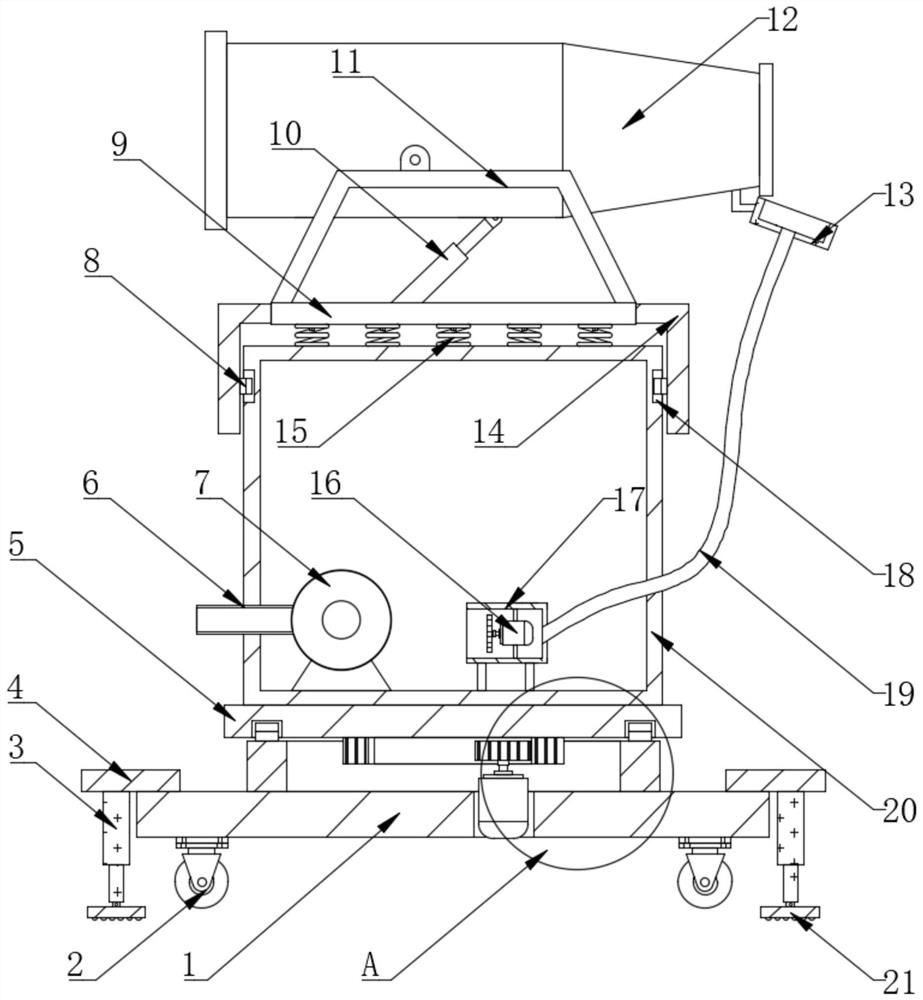

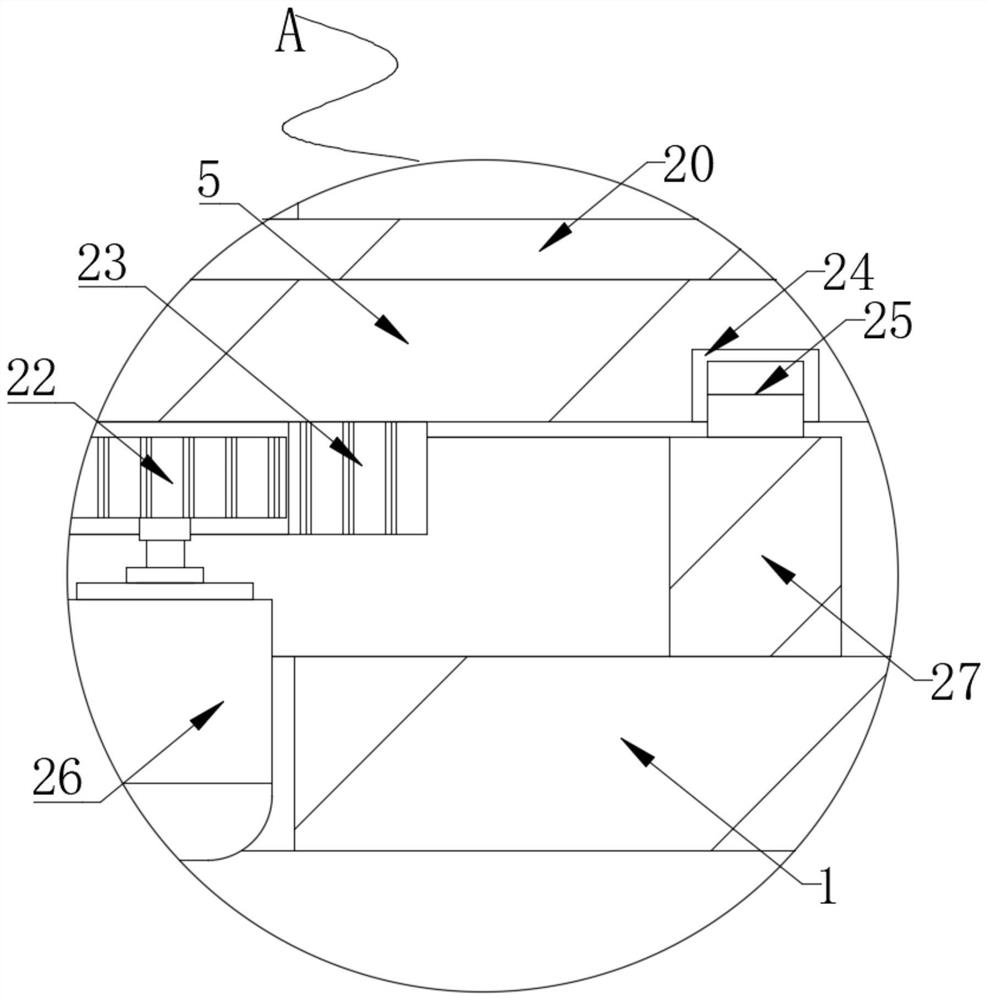

[0024] see Figure 1~2 , in an embodiment of the present invention, a dust suppression device includes a base 1, the four corners of the bottom of the base 1 are connected with moving wheels 2, and the top of the base 1 is provided with an electrical box 20, and the inside of the electrical box 20 is connected with a water pump 7, One side of the water pump 7 is connected with an external water pipe 6, and the top of the electrical box 20 is provided with a fog cannon support seat 9, and both sides of the top of the fog cannon support seat 9 are connected with a fog cannon support 11, and the top of the fog cannon support seat 9 is provided with a hydraulic pressure Push rod 10, one side of two fog cannon brackets 11 are connected with fog cannon 12, the top of base 1 is connected with support ring 27, the top of base 1 is provided with installation groove, and the interior of installation groove is provided with motor 26, The top of the support ring 27 is equipped with an ann...

Embodiment 2

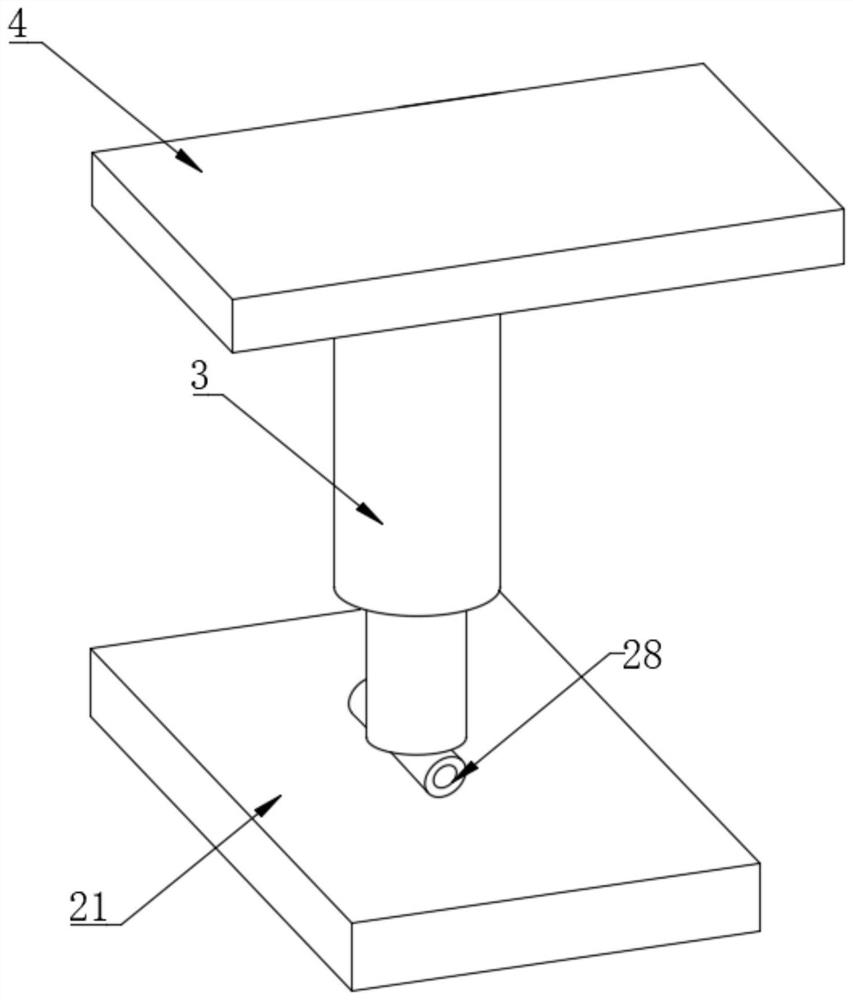

[0032] refer to figure 1 with 3 , a dust suppression device, compared with Embodiment 1, this embodiment also includes two reaction force plates 4 connected to both sides of the top of the base 1, and a hydraulic jack 3 is installed at the bottom of the reaction force plate 4, and the hydraulic jack 3 The bottom end is provided with a support plate 21.

[0033] Wherein, a hinge 28 is arranged between the hydraulic jack 3 and the support plate 21 , the hydraulic jack 3 and the support plate 21 are rotatably connected by the hinge 28 , and the bottom end of the support plate 21 is provided with an anti-slip pad.

[0034]Working principle: Due to the complex environment of the construction site, the base 1 may be dumped and shifted in position on the construction site. At this time, after the base 1 is moved to the designated position, the four hydraulic jacks 3 are turned on, so that the hydraulic jacks 3 drive the The supporting plate 21 that it connects moves toward the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com