Preparation method of cross-linked hyaluronic acid filling agent for injection

A technology of cross-linked hyaluronic acid and hyaluronic acid is applied in the preparation of injectable cross-linked hyaluronic acid long-acting filler for soft tissue filling and the preparation of cross-linked hyaluronic acid filler for injection, which can solve difficult problems. Realize the problems of microsphere preparation, low mechanical properties of microspheres, and difficult operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example mainly studies the effect of the sodium hyaluronate content in the aqueous phase on the cross-linked sodium hyaluronate microspheres. The preparation method is as follows:

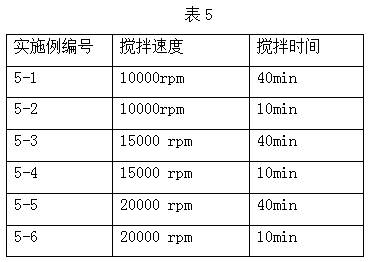

[0043] 1. Maintain a low temperature environment of 2-8°C, add 0.4g BDDE to 16mL water and mix well, then add different qualities of sodium hyaluronate (molecular weight 2000KDa), mix well to get gel 1, add 20 mL 1 to gel 1 Wt% NaOH solution was dispersed by a high-shear dispersing emulsification homogenizer at a speed of 15,000 rpm for 20 min to obtain gel 2, which is the aqueous phase.

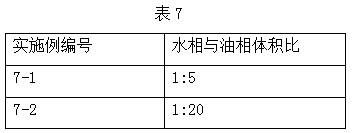

[0044] 2. Add gel 2 to 400mL n-octane containing 2wt% Span80, emulsify with a high-shear dispersing emulsifying homogenizer at 20,000 rpm for 10 minutes, and let stand to remove air bubbles after emulsification is uniform.

[0045] 3. After the emulsification is completed, the temperature of the emulsion is controlled at 30°C, and it is stirred for 12 hours to carry out cross-linking.

[0046] 4. Aft...

Embodiment 2

[0051] This example mainly studies the effect of the amount of cross-linking agent in the water phase on the cross-linked sodium hyaluronate microspheres. The preparation method is as follows:

[0052] 1. Maintain a low temperature environment of 2-8°C, add BDDE of different qualities to 16mL water and mix well, then add 4 g sodium hyaluronate (molecular weight 2000KDa), mix well to obtain gel 1, add 20 mL 1 to gel 1 Wt% NaOH solution was dispersed by a high-shear dispersing emulsification homogenizer at a speed of 15,000 rpm for 20 min to obtain gel 2, which is the aqueous phase.

[0053] 2. Add gel 2 to 400mL cyclohexane containing 2wt% Span80, and emulsify with a high-shear dispersing emulsifying homogenizer at 20,000 rpm for 10 minutes. After the emulsification is uniform, let stand to remove air bubbles.

[0054] 3, with embodiment 1.

[0055] 4, with embodiment 1.

[0056] 5. Same as embodiment 1.

[0057] The amount of crosslinking agent is shown in Table 2 below.

...

Embodiment 3

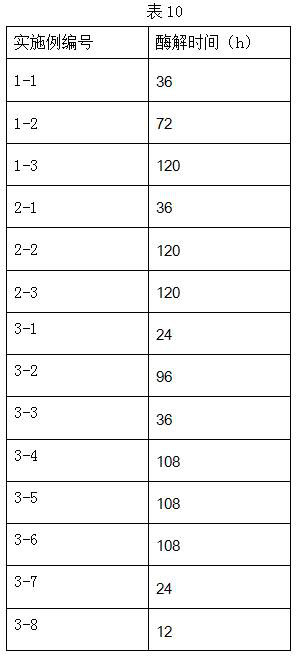

[0060] This example mainly studies the influence of crosslinking temperature and crosslinking time on crosslinked sodium hyaluronate microspheres. The preparation method is as follows:

[0061] 1. Maintain a low temperature environment of 2-8°C, add 0.4g BDDE to 16mL water and mix well, then add 4 g sodium hyaluronate (molecular weight 2000KDa), mix well to obtain gel 1, add 20 mL 1 wt% to gel 1 NaOH solution was dispersed by a high-shear dispersing emulsification homogenizer at a speed of 15,000 rpm for 20 min to obtain gel 2, which is the aqueous phase.

[0062] 2, with embodiment 1.

[0063] 3. After the emulsification is completed, the temperature and time of the emulsion are controlled to carry out cross-linking.

[0064] 4, with embodiment 1.

[0065] 5. Same as embodiment 1.

[0066] The crosslinking temperature and crosslinking time are shown in Table 3 below.

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com