Method for improving solubility of dual hydrophobic protein

A hydrophobic protein and hydrophobic technology, which is applied in the preparation method of peptides, plant protein processing, chemical instruments and methods, etc., can solve the problems that the solubility of two hydrophobic proteins cannot be improved at the same time, and the primary structure and nutritional value of the protein are destroyed. Achieve the feasibility of large-scale industrial application, novel technology, and the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

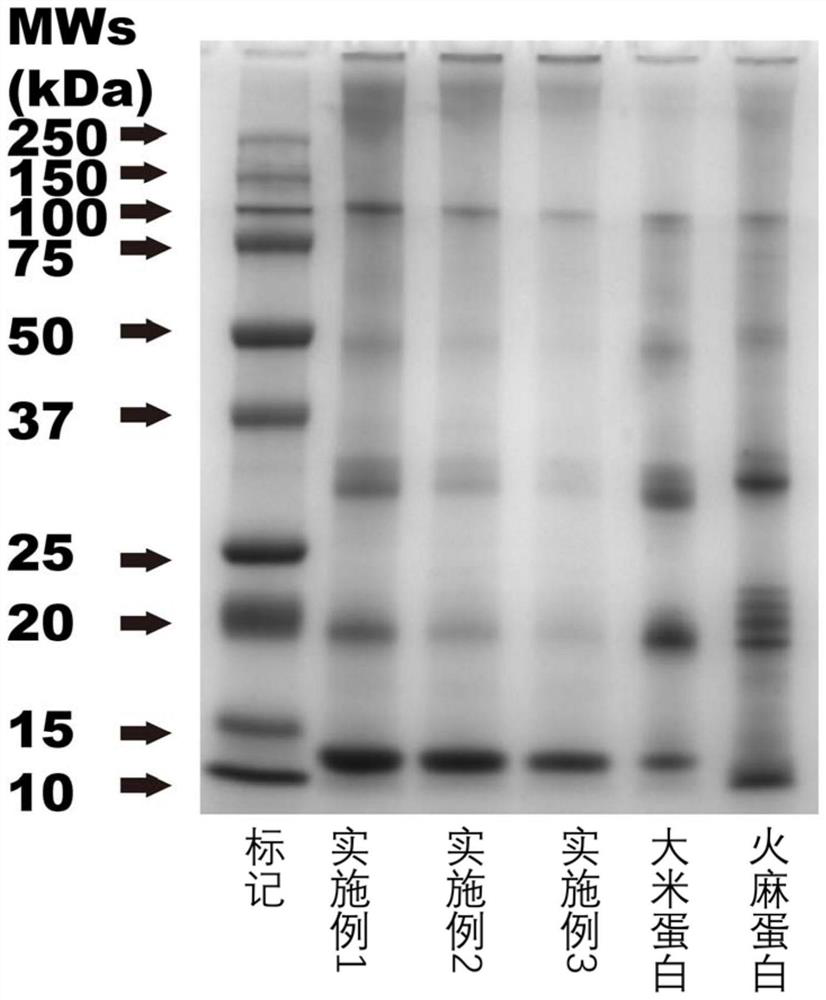

[0033] A method for increasing the solubility of a doubly hydrophobic protein comprising the steps of:

[0034] (1) Alkali dispersion: put rice protein and hemp protein into distilled water at a mass ratio of 1:0.2, stir well, add alkali solution to adjust pH=10;

[0035] (2) Structure unfolding: Stir the feed solution obtained in step (1) for 60 minutes at a stirring rate of 600 r / min, so that the structures of the two proteins in the solution are fully unfolded and the secondary structure is exposed;

[0036] (3) Hydrophobic binding: Stir the feed solution obtained in step (2) for 60 min at a stirring rate of 900 r / min, and at the same time add acid solution dropwise to adjust the pH to 7.0, so that the two proteins can pass through the hydrophobic interaction between the secondary structures produce a combination;

[0037] (4) Desalination by dialysis: dialyze the feed liquid obtained in step (3) for 22 hours through a dialysis bag;

[0038] (5) centrifugation: centrifuge...

Embodiment 2

[0041] A method for increasing the solubility of a doubly hydrophobic protein comprising the steps of:

[0042] (1) Alkali dispersion: put rice protein and walnut protein into distilled water at a mass ratio of 1:0.5, stir well, add alkali solution to adjust pH=11;

[0043] (2) Structure development: Stir the feed liquid obtained in step (1) for 100 min at a stirring rate of 900 r / min, so that the structures of the two proteins in the solution are fully developed and the secondary structure is exposed;

[0044] (3) Hydrophobic binding: Stir the feed solution obtained in step (2) for 45 minutes at a stirring rate of 900 r / min, and at the same time add acid solution dropwise to adjust the pH to 7.0, so that the two proteins can pass through the hydrophobic interaction between the secondary structures Combine;

[0045] (4) Desalination by dialysis: dialyze the feed liquid obtained in step (3) for 24 hours through a dialysis bag;

[0046] (5) centrifugation: centrifuge the feed ...

Embodiment 3

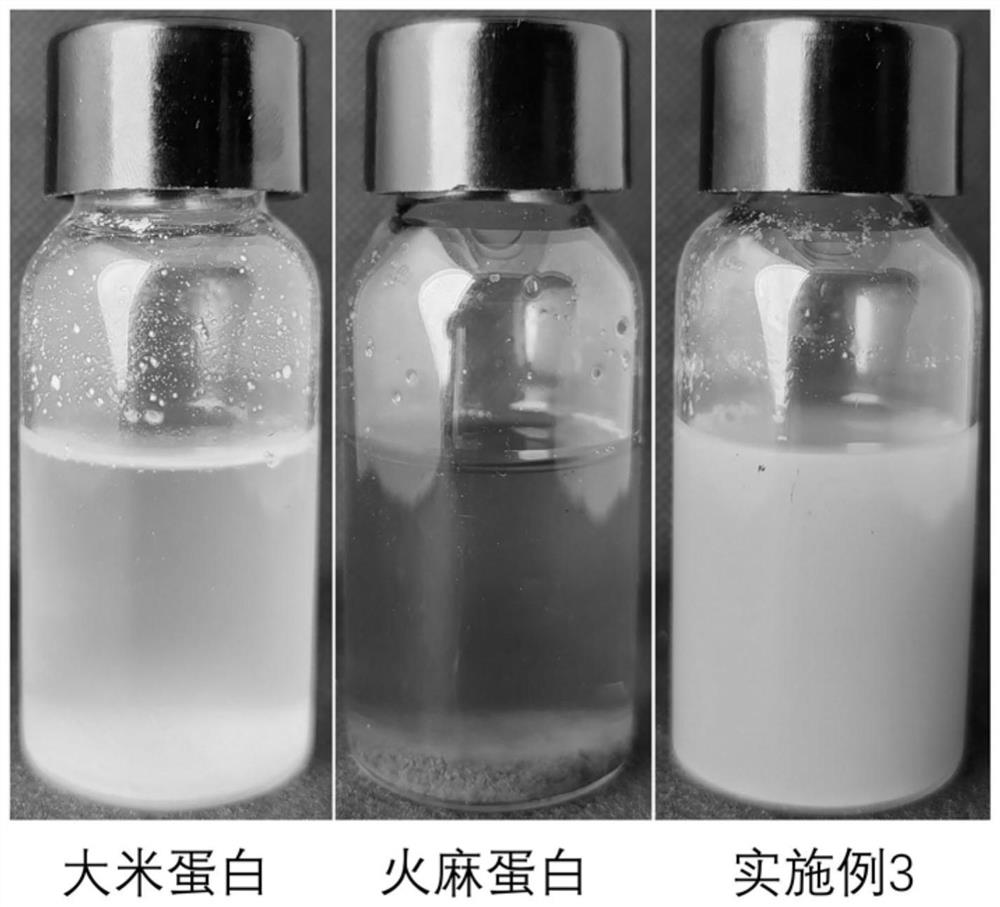

[0049] A method for increasing the solubility of a doubly hydrophobic protein comprising the steps of:

[0050] (1) Alkali dispersion: Put rice protein and hemp protein into distilled water at a mass ratio of 1:1, stir well, add alkali solution to adjust pH=12;

[0051](2) Structure unfolding: Stir the feed solution obtained in step (1) for 45 minutes at a stirring rate of 1200 r / min, so that the structures of the two proteins in the solution are fully unfolded and the secondary structure is exposed;

[0052] (3) Hydrophobic binding: Stir the feed liquid obtained in step (2) at a stirring rate of 600r / min for 75min, and at the same time add acid solution dropwise to adjust the pH to 7.0, so that the two proteins can pass through the hydrophobic interaction between the secondary structures combined;

[0053] (4) Desalination by dialysis: dialyze the feed liquid obtained in step (3) for 26 hours through a dialysis bag;

[0054] (5) centrifugation: centrifuge the feed liquid ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com